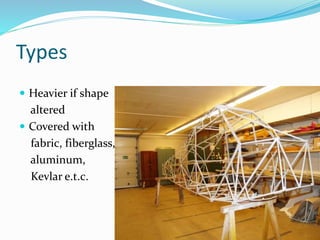

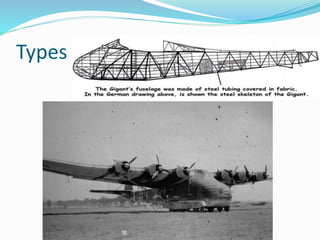

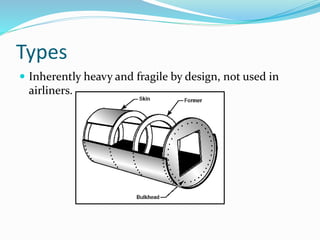

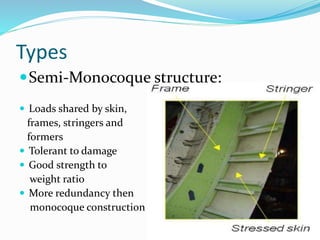

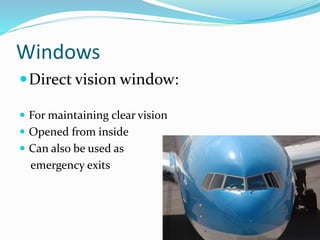

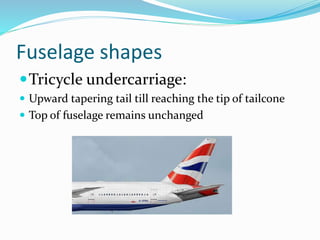

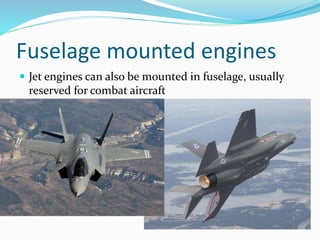

The document discusses the different types and functions of aircraft fuselages. It describes how fuselages form the main body of an aircraft and house key components. There are three main types of fuselage structures: frame, monocoque, and semi-monocoque. Frame structures use a series of pipes but are heavier, while monocoque structures rely on the skin to take all loads but are fragile. Semi-monocoque fuselages provide a balance by sharing loads between the skin and internal structures. The document also outlines features like windows, doors, engines mounts and shapes that fuselages can take.