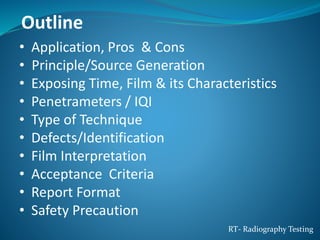

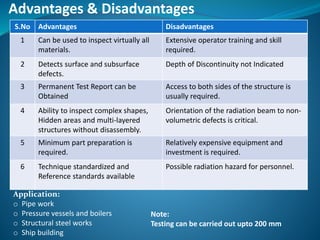

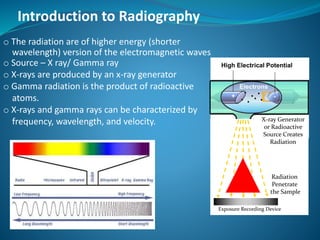

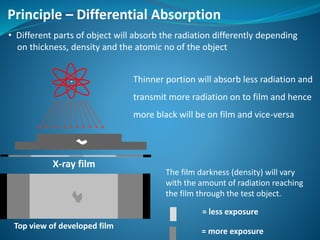

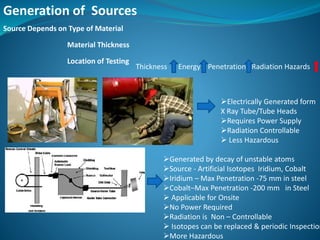

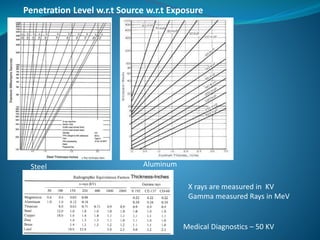

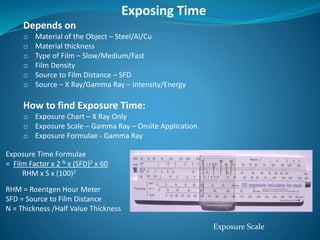

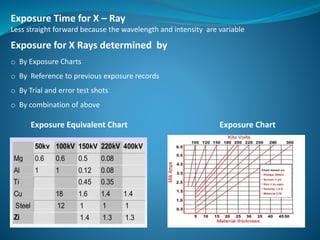

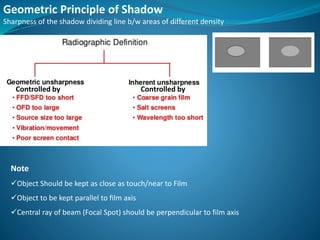

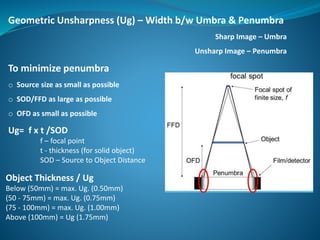

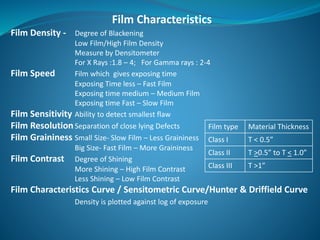

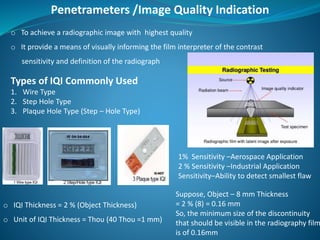

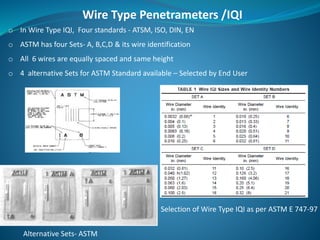

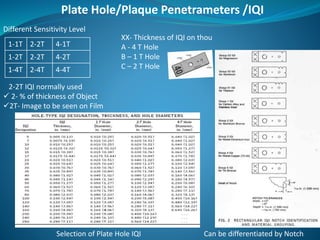

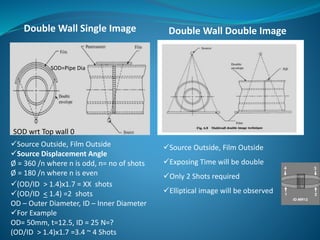

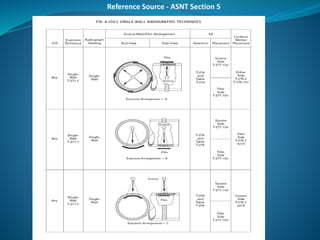

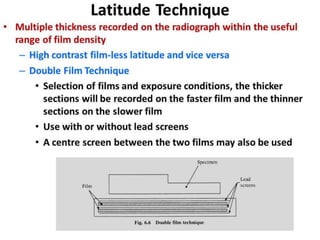

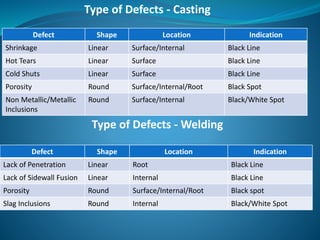

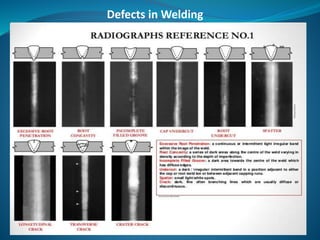

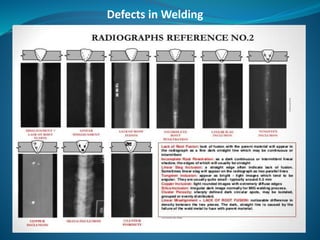

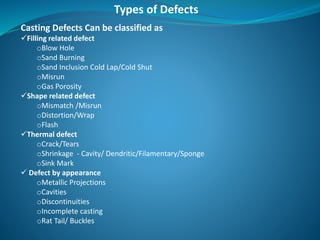

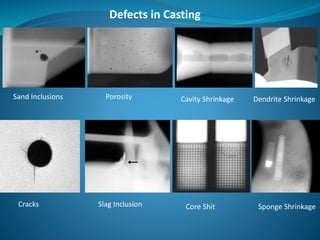

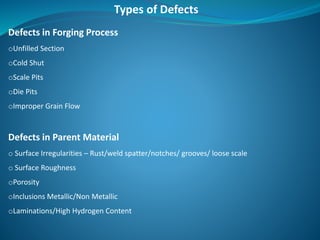

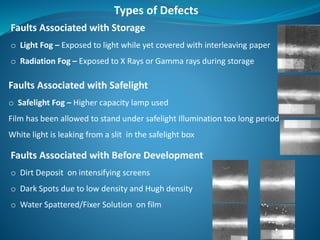

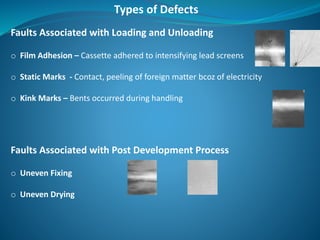

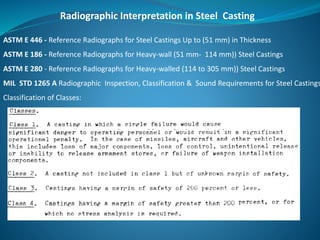

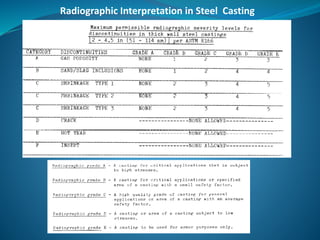

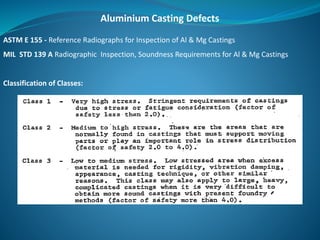

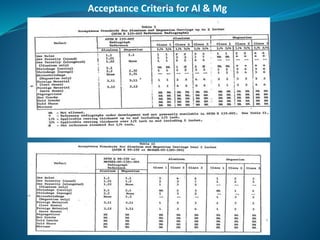

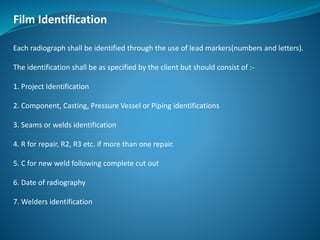

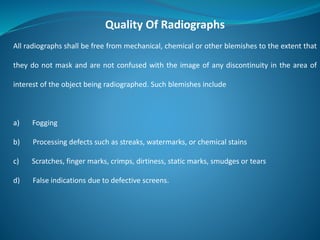

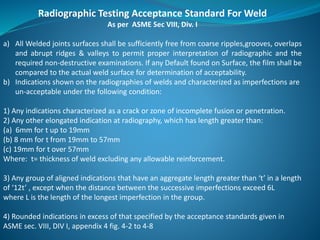

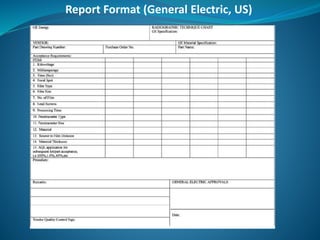

The document presents a comprehensive overview of radiography testing including its applications, principles, techniques, and associated advantages and disadvantages. It covers film characteristics, exposure time calculations, various defects in materials, and standards for interpreting radiographs. Safety precautions and reporting formats for radiographic evaluations are also discussed.