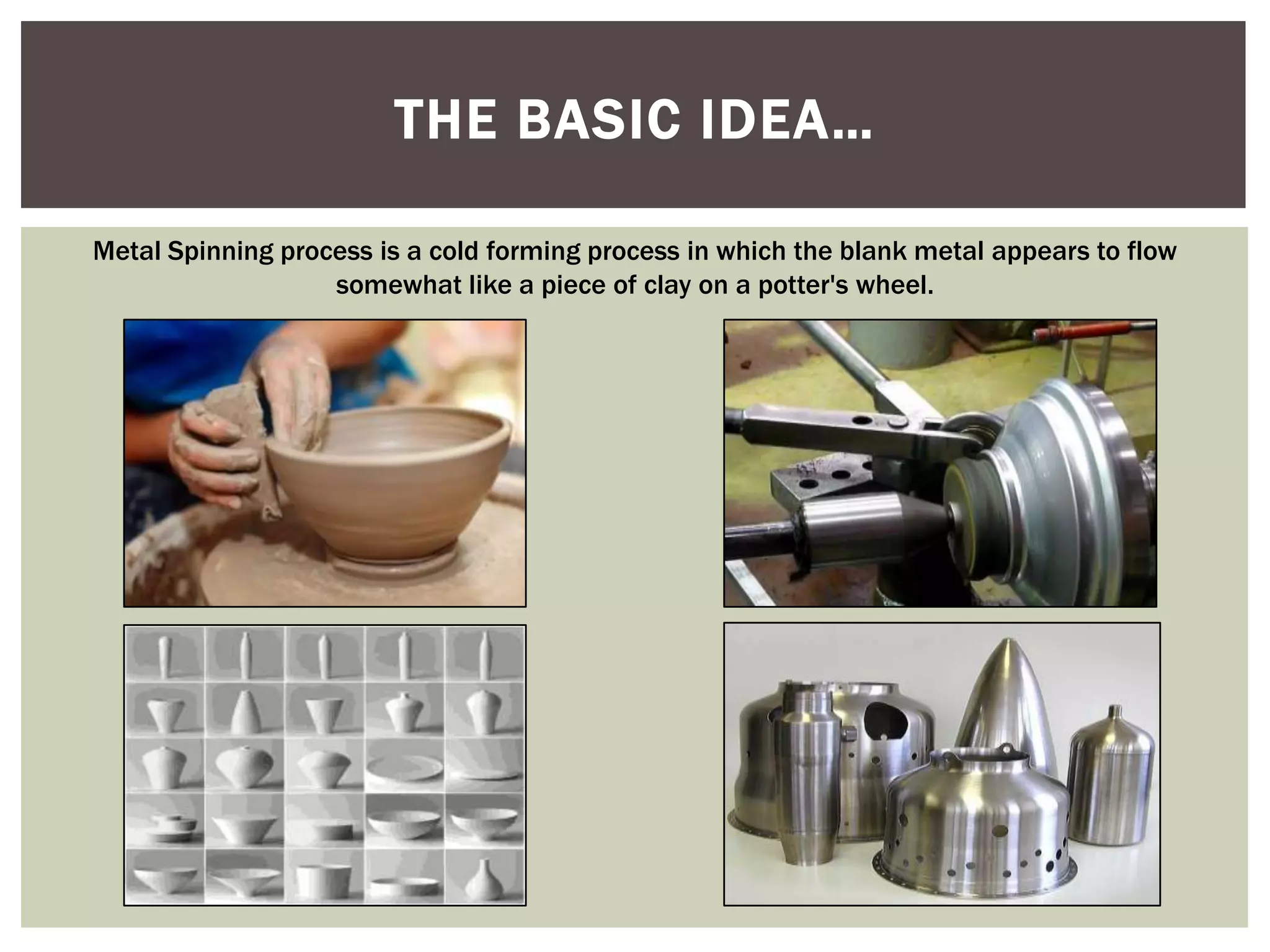

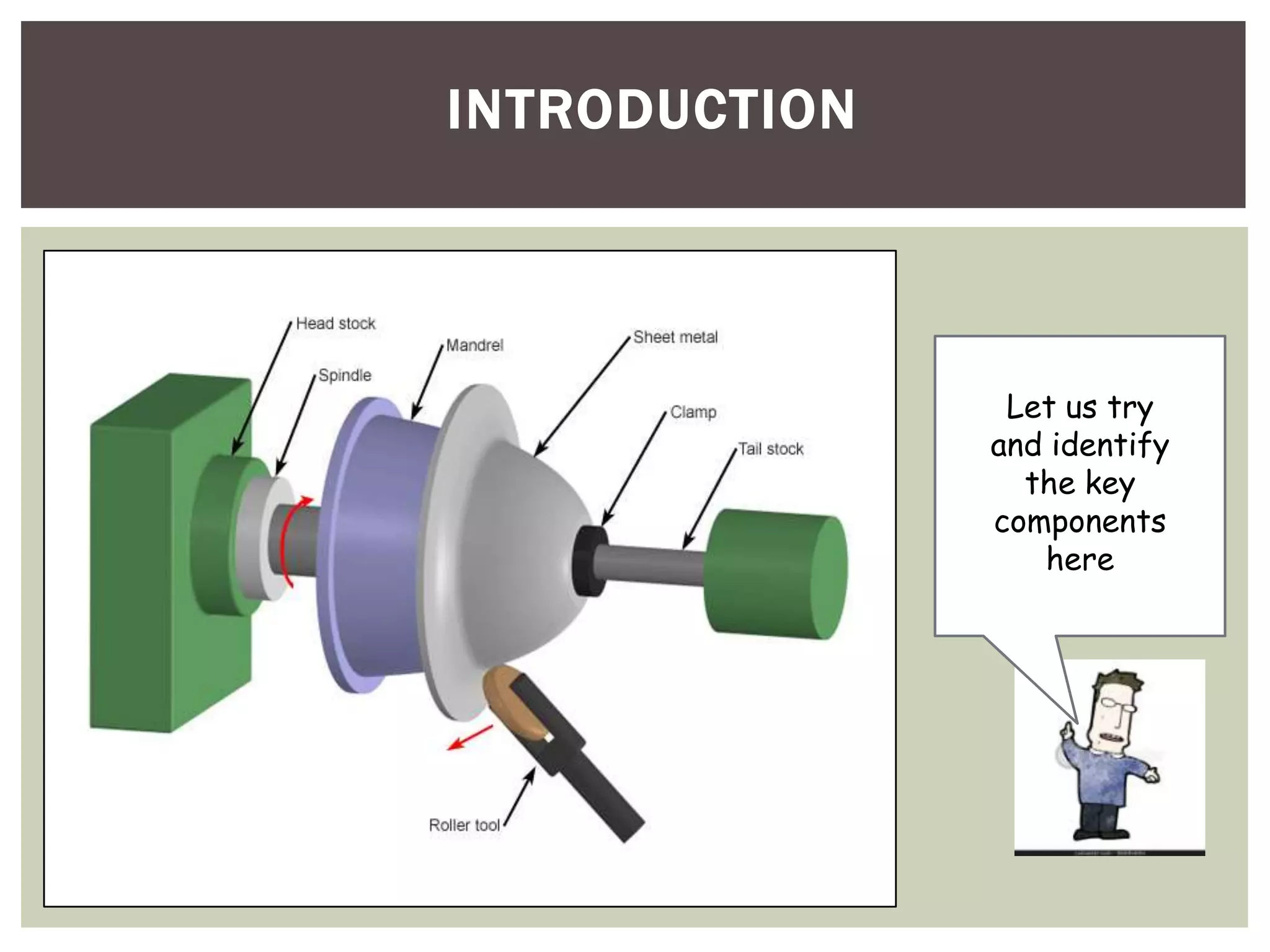

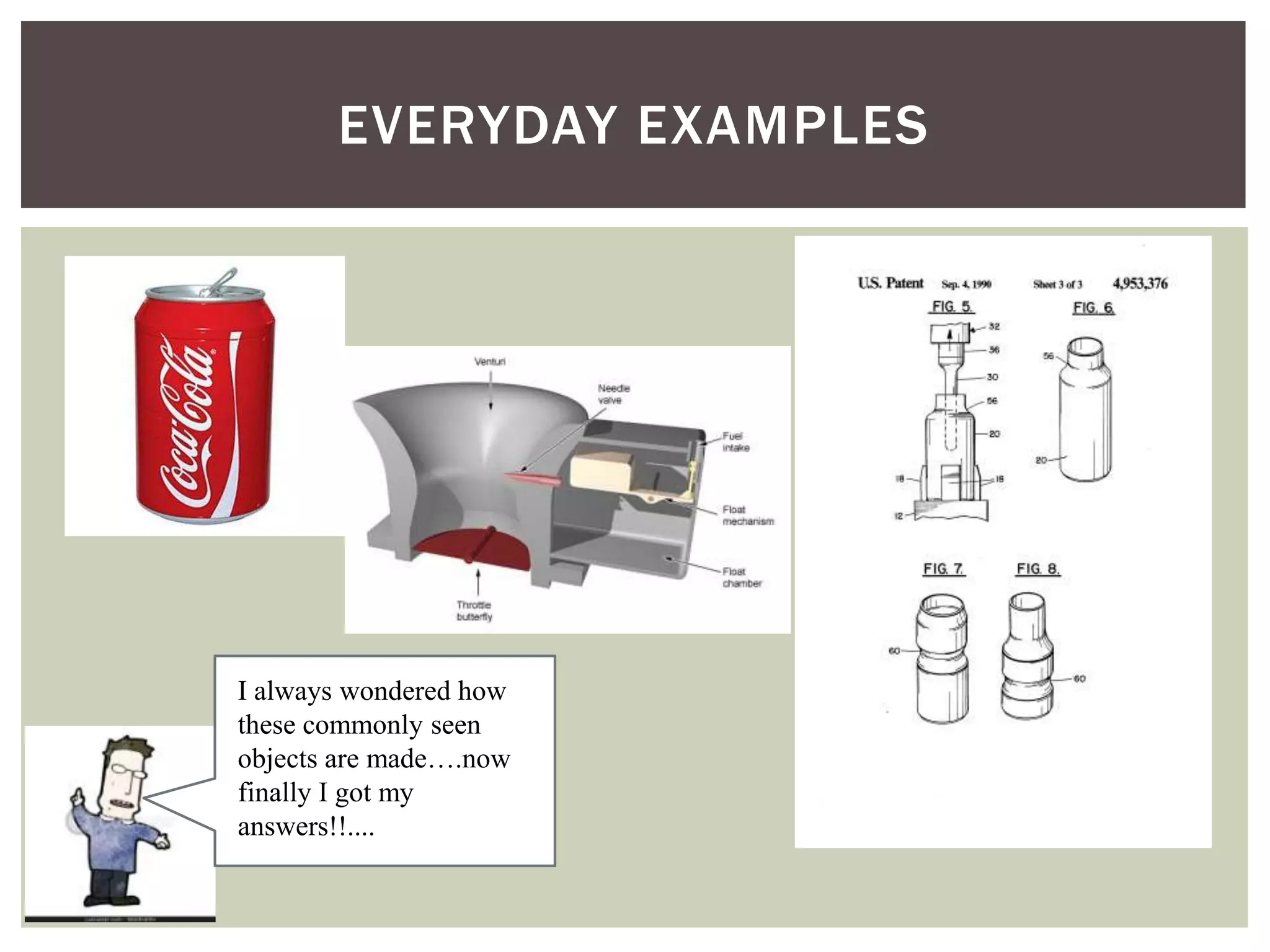

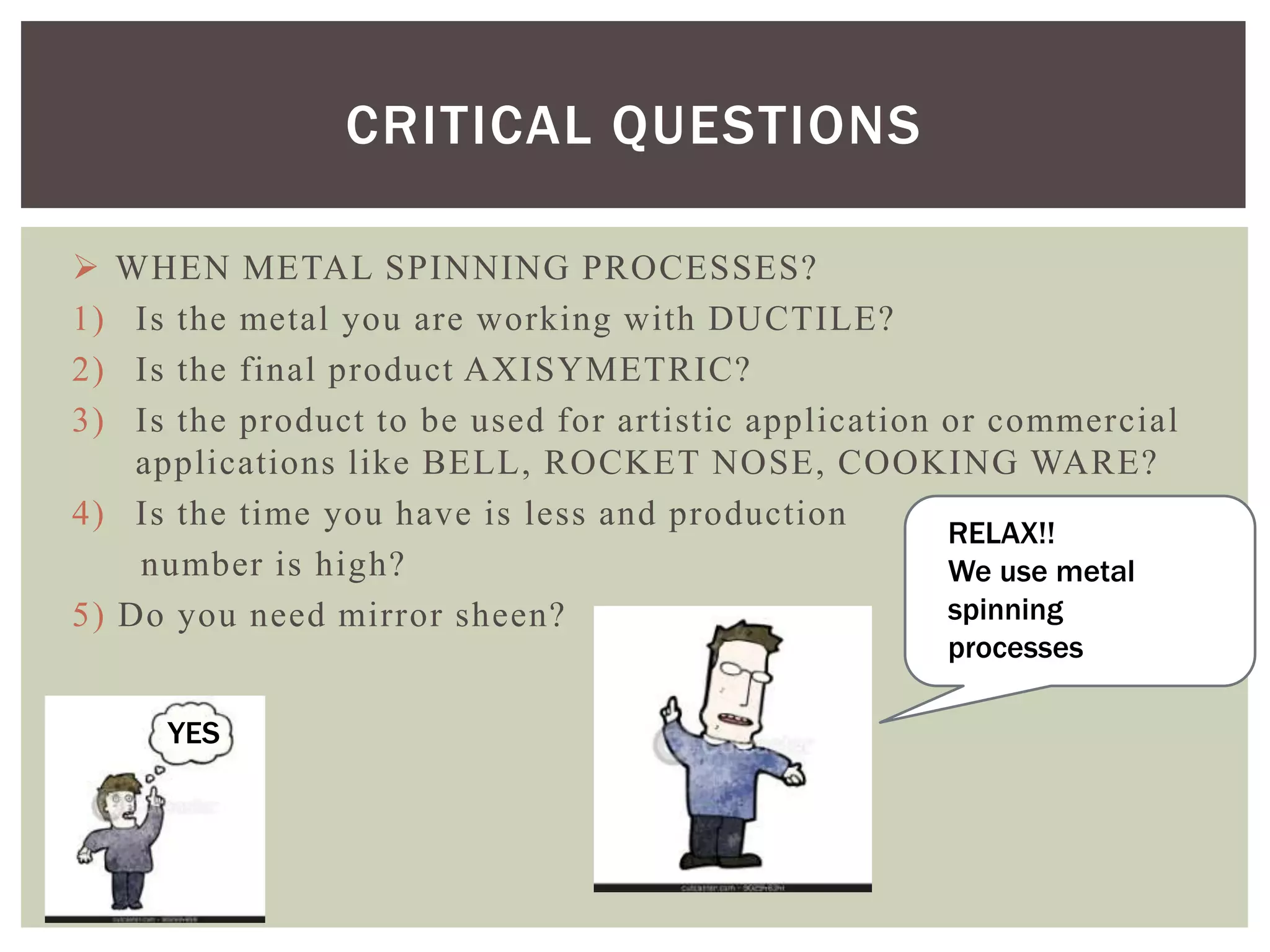

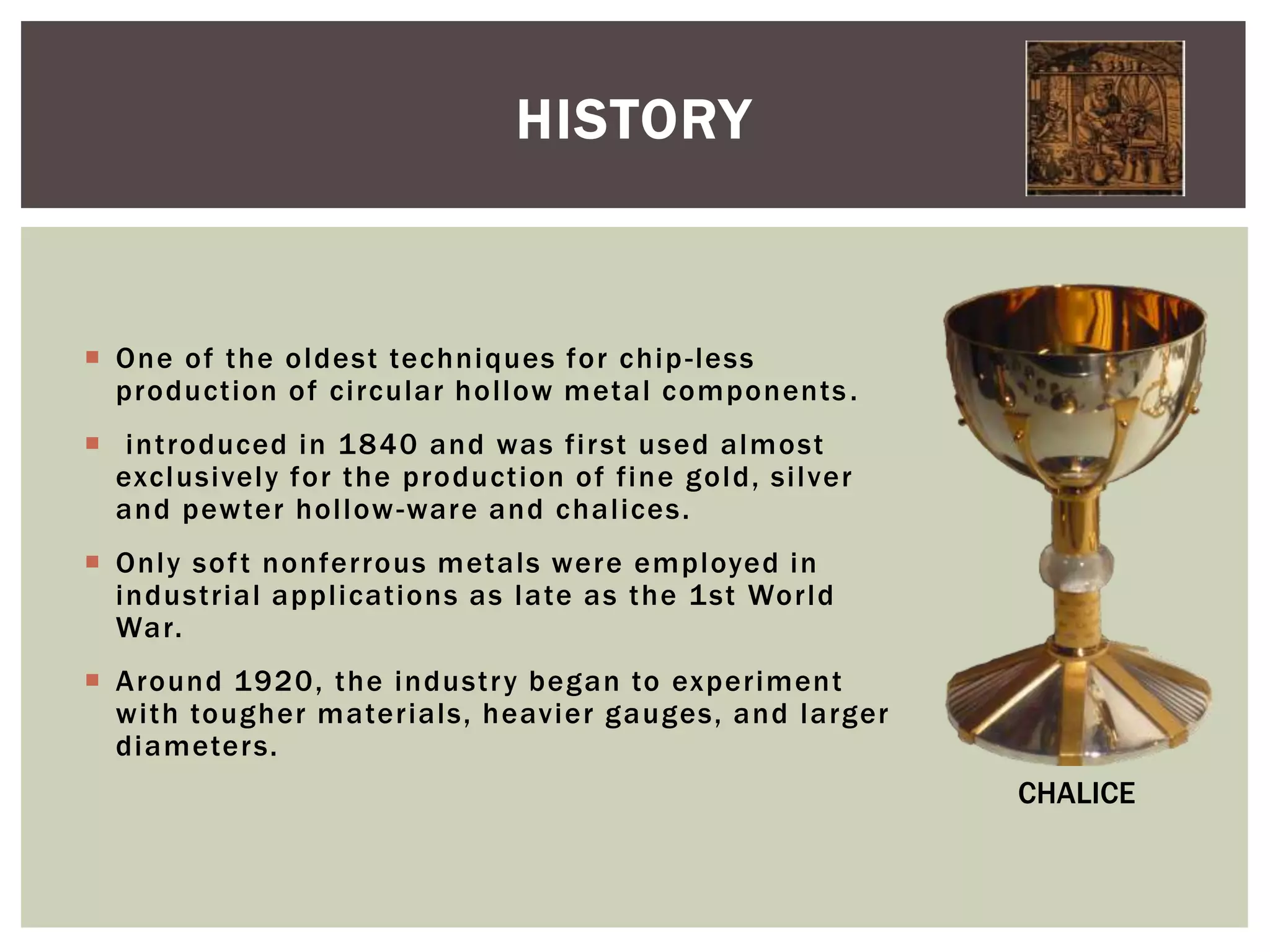

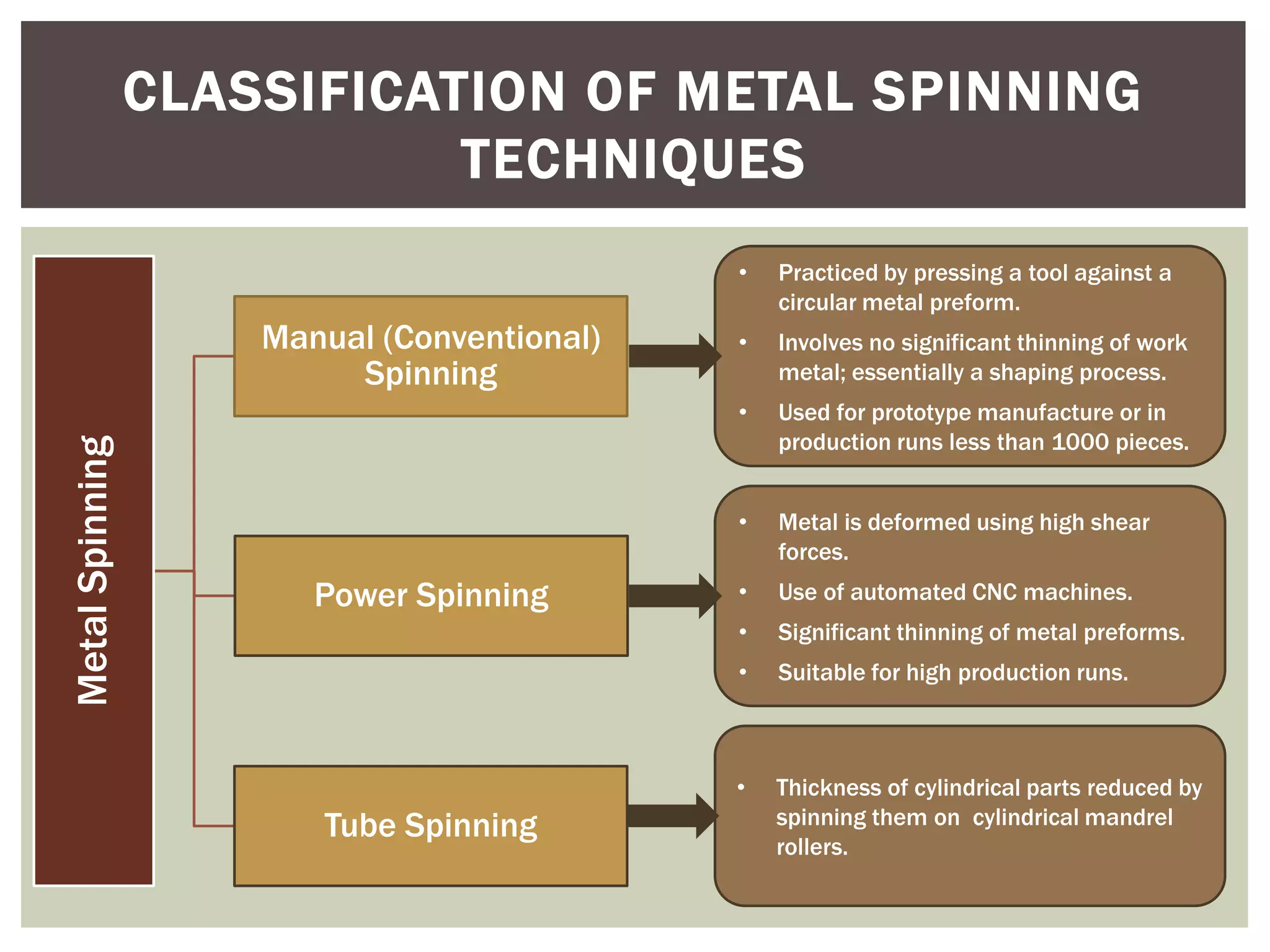

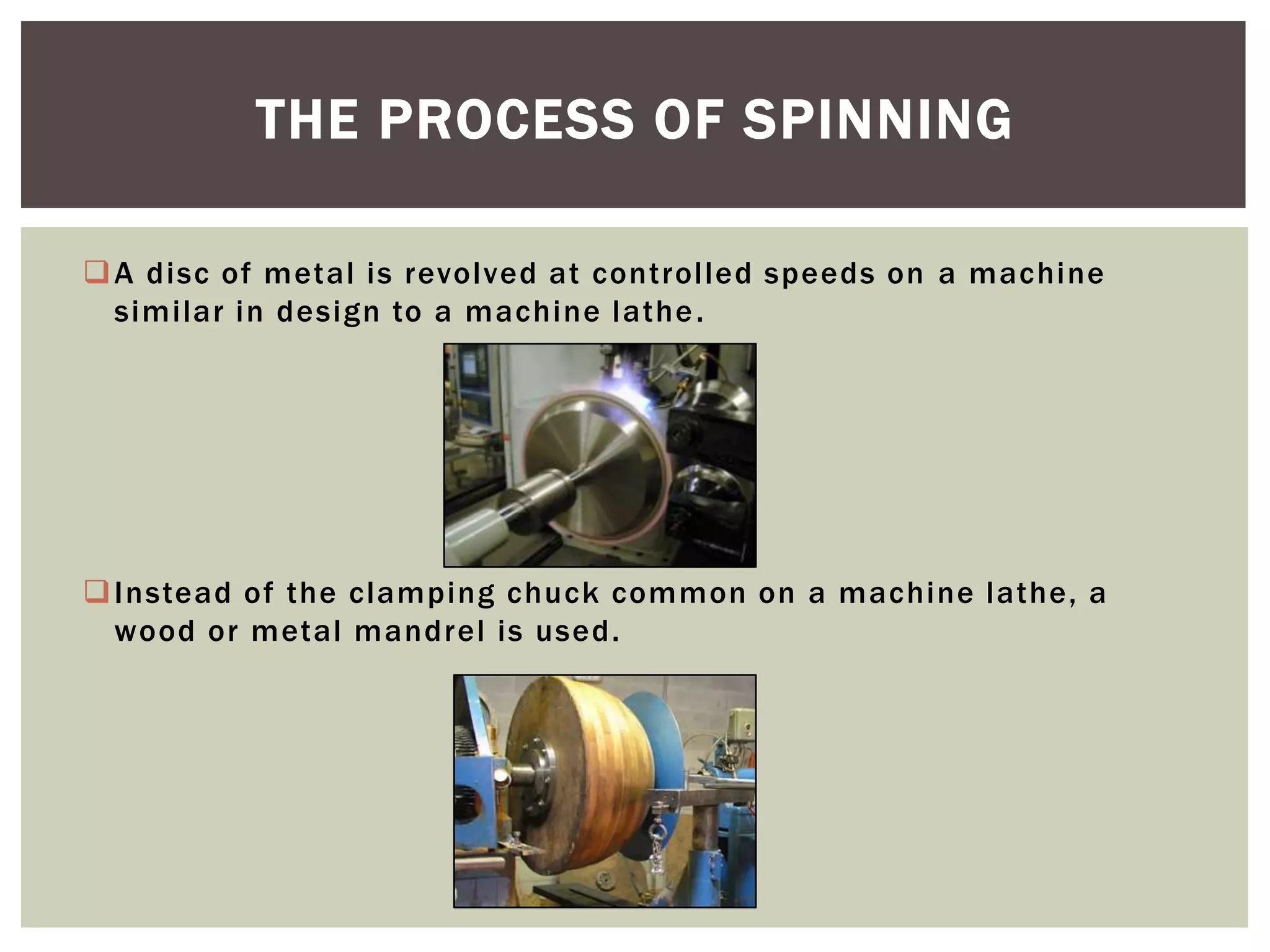

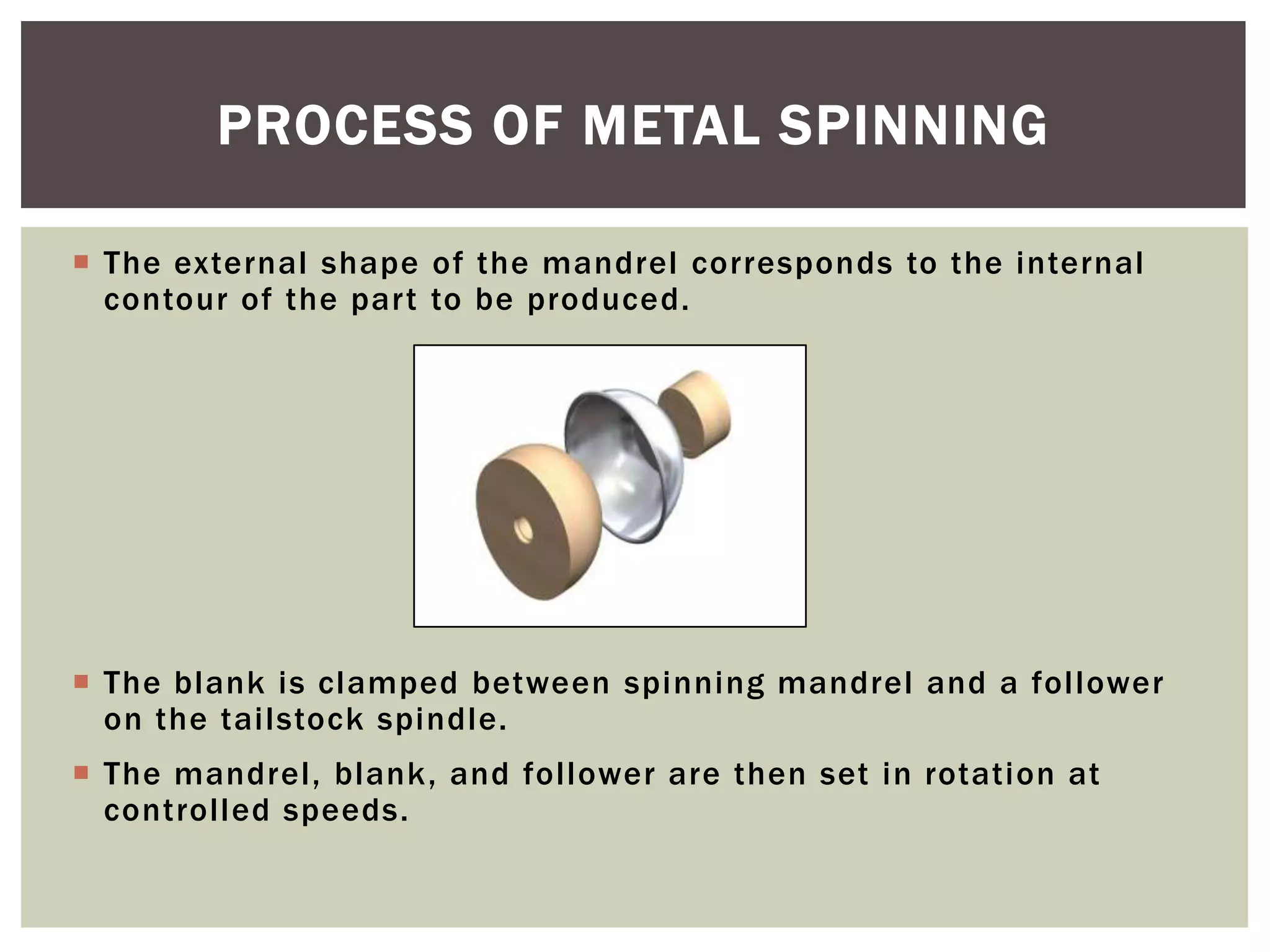

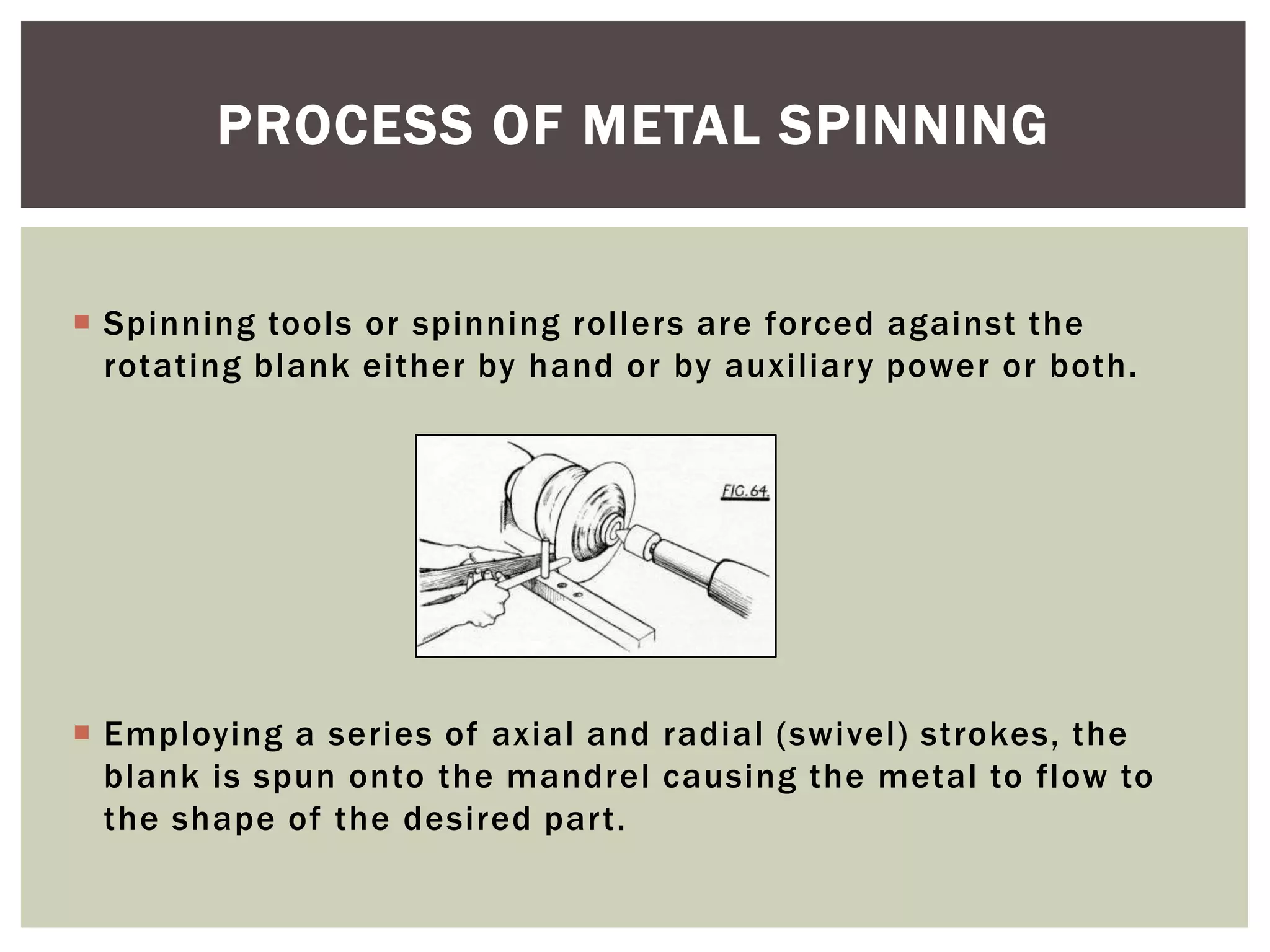

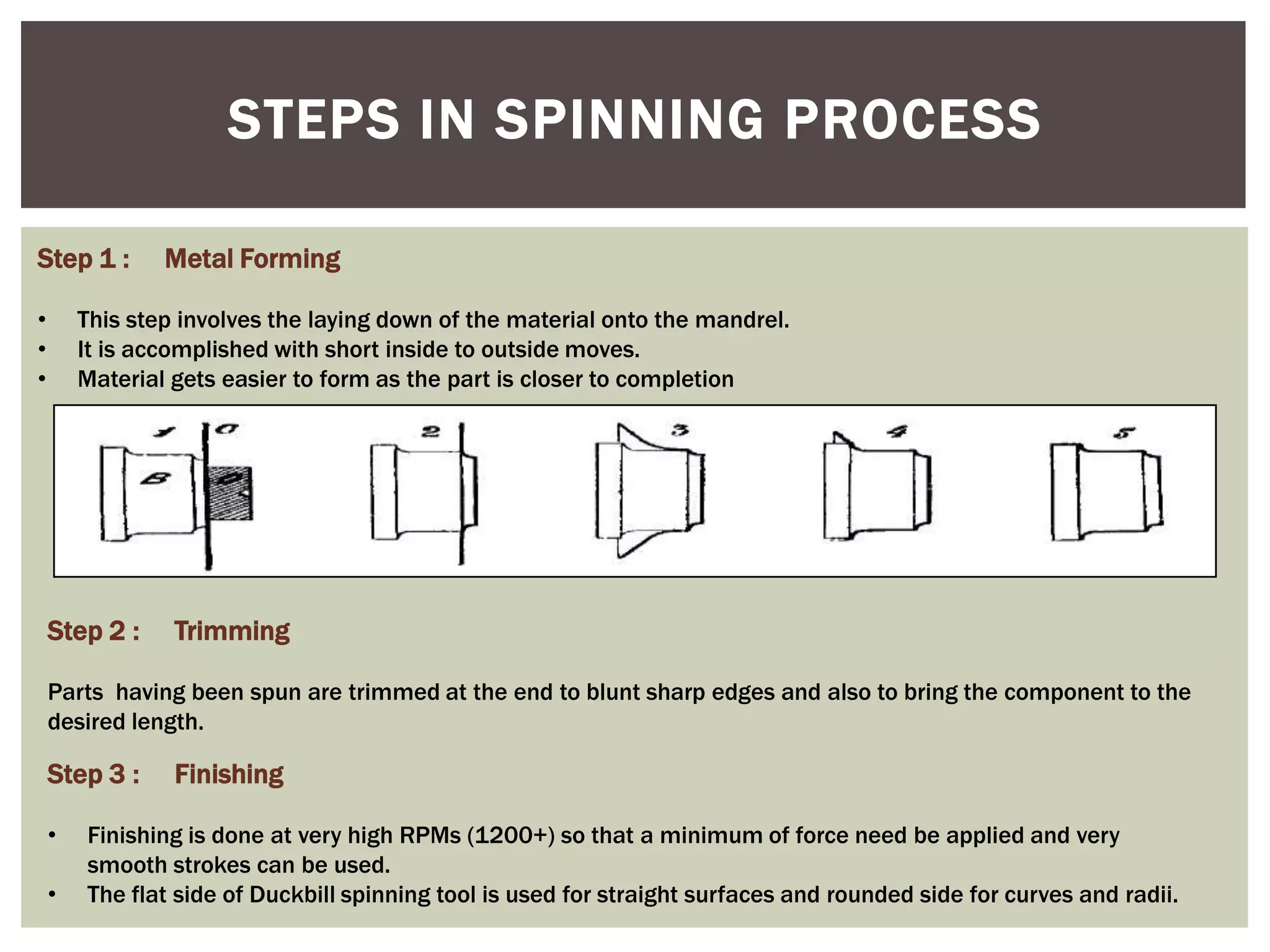

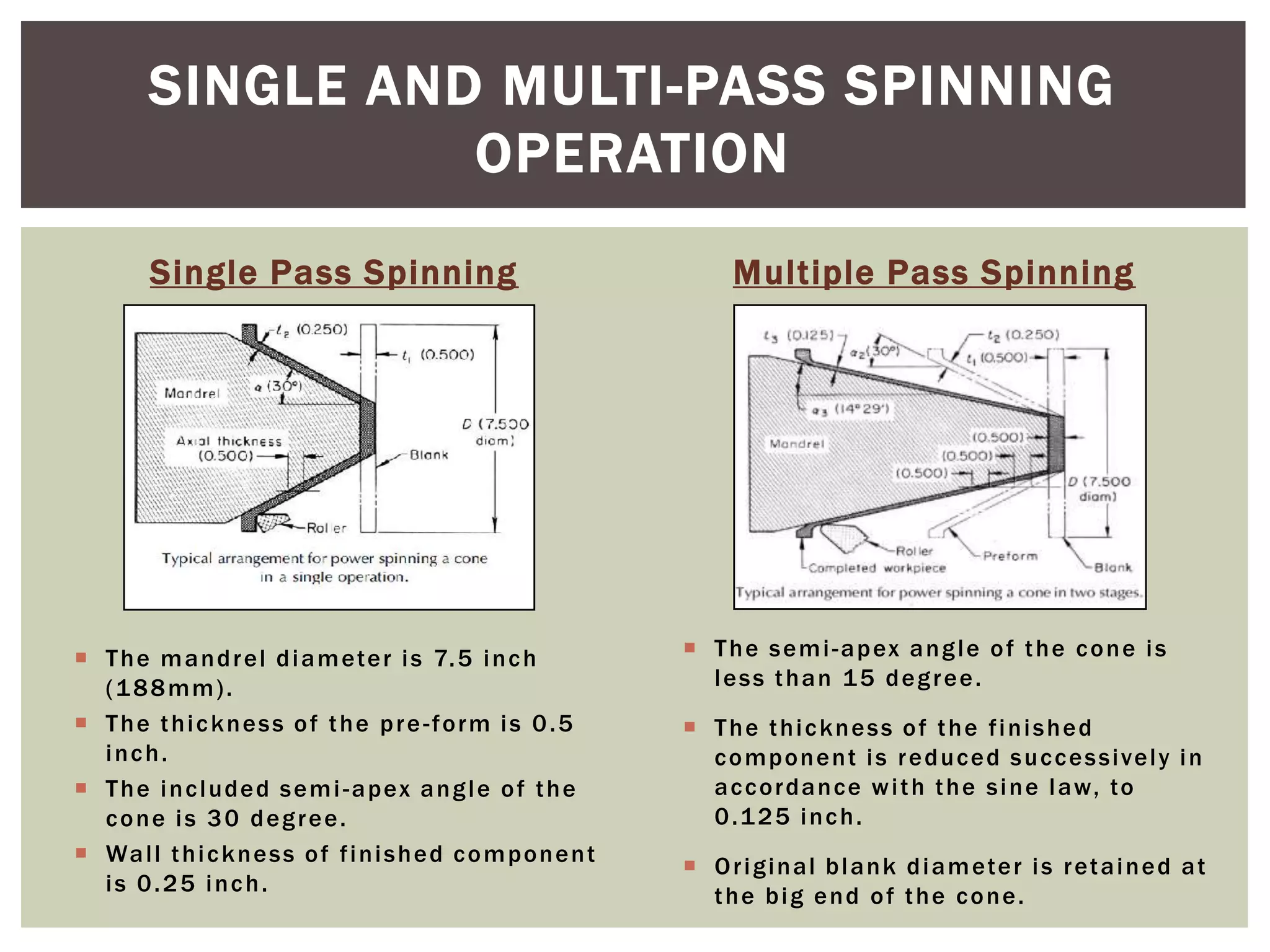

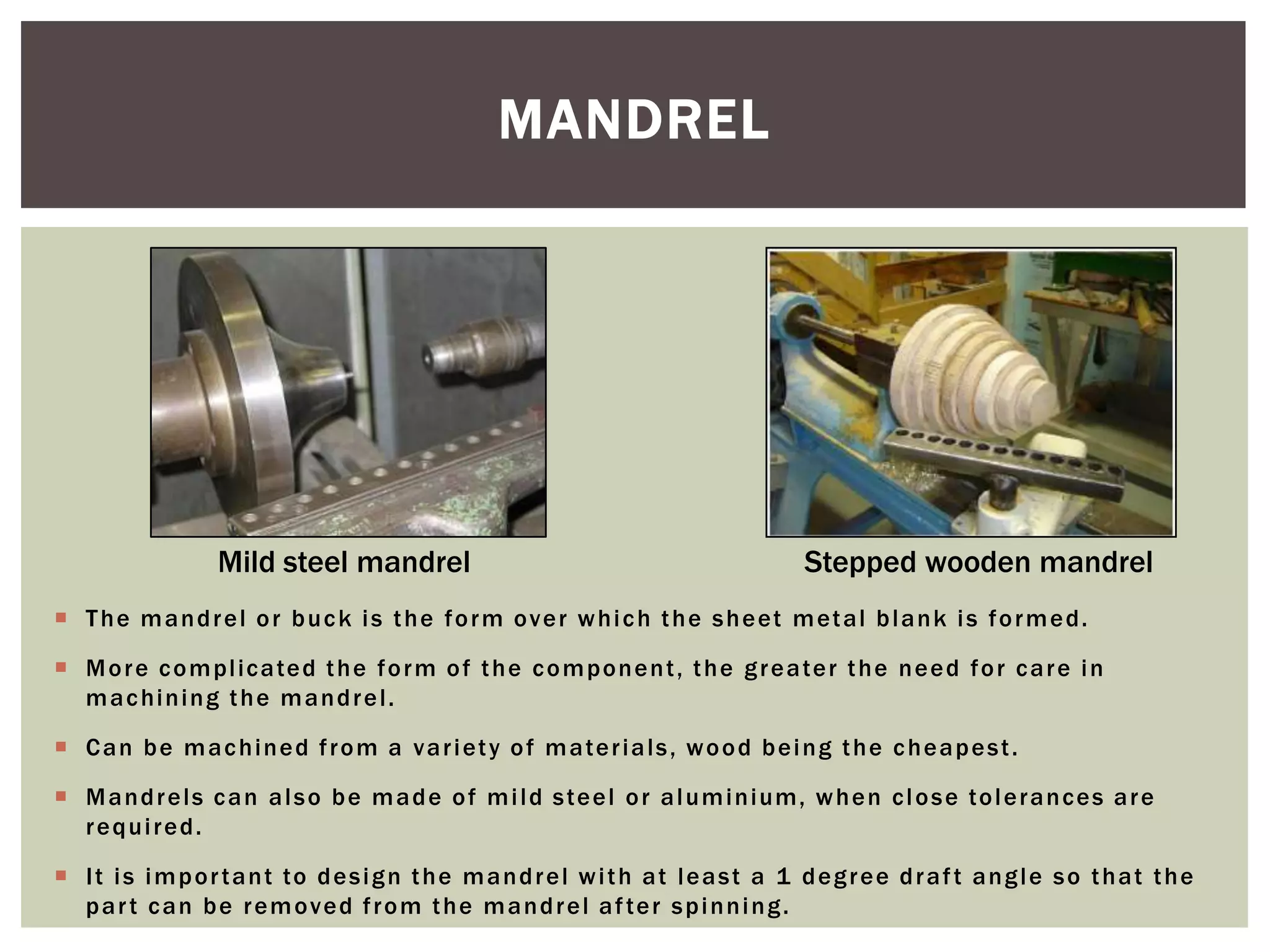

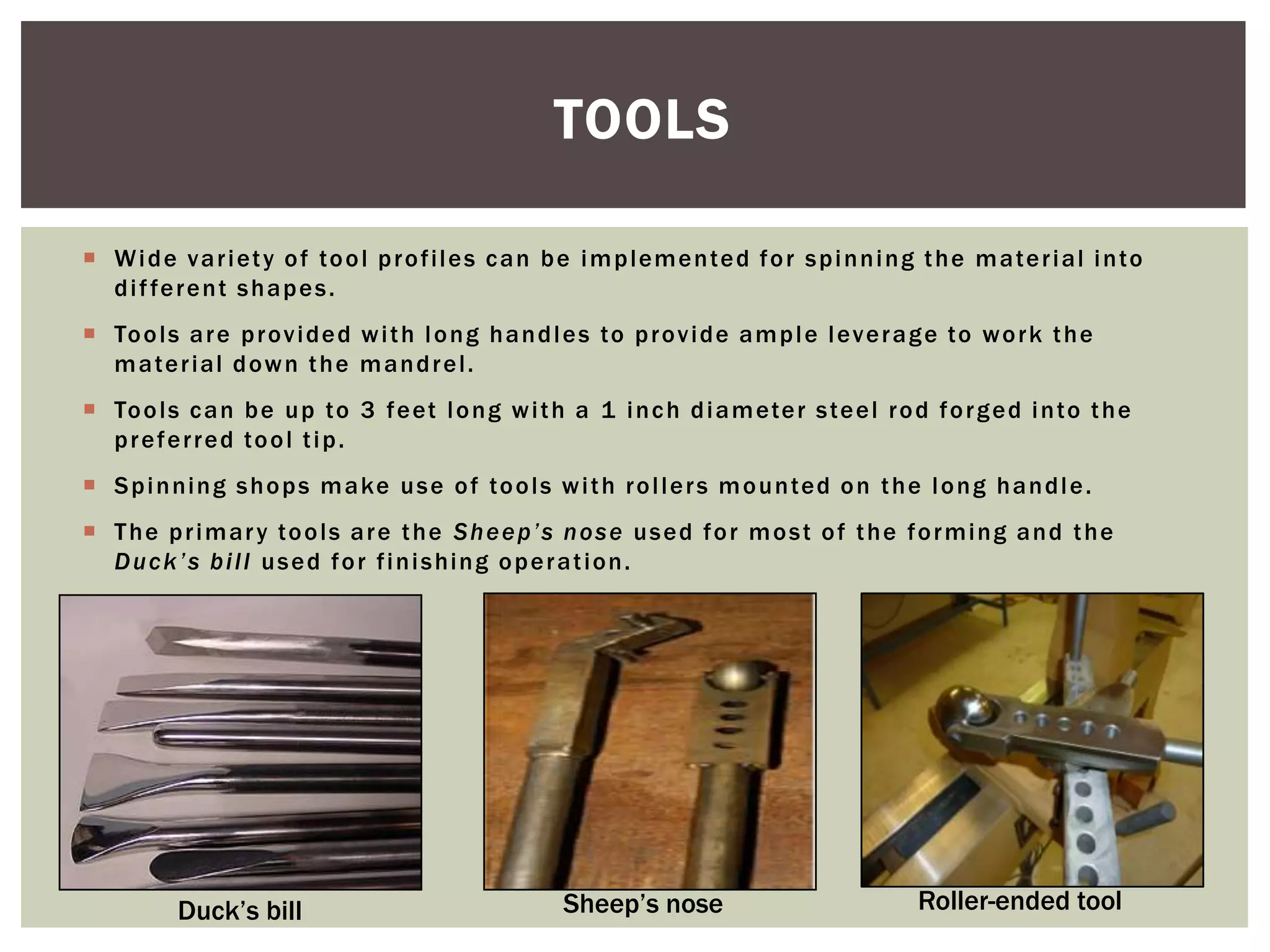

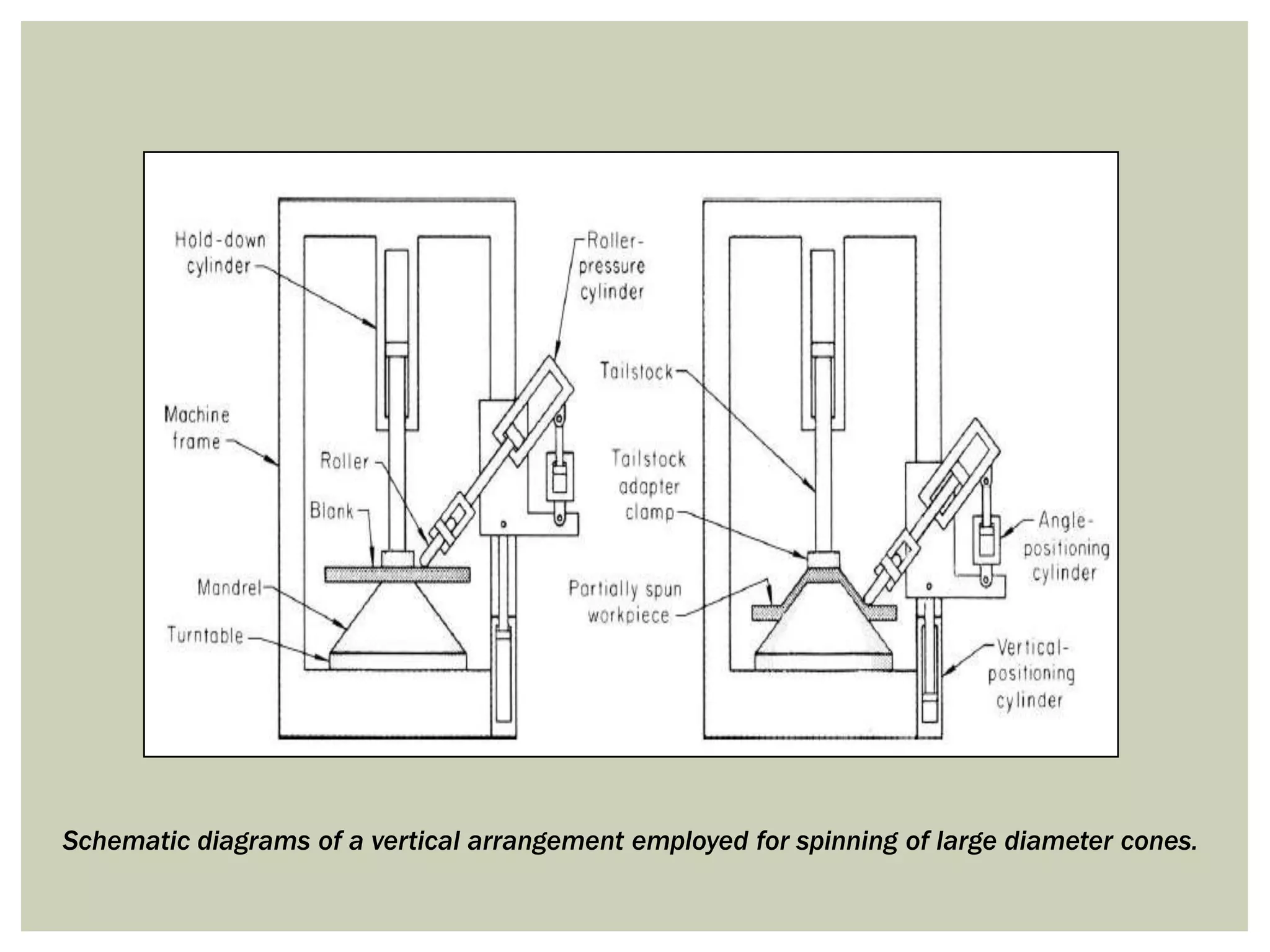

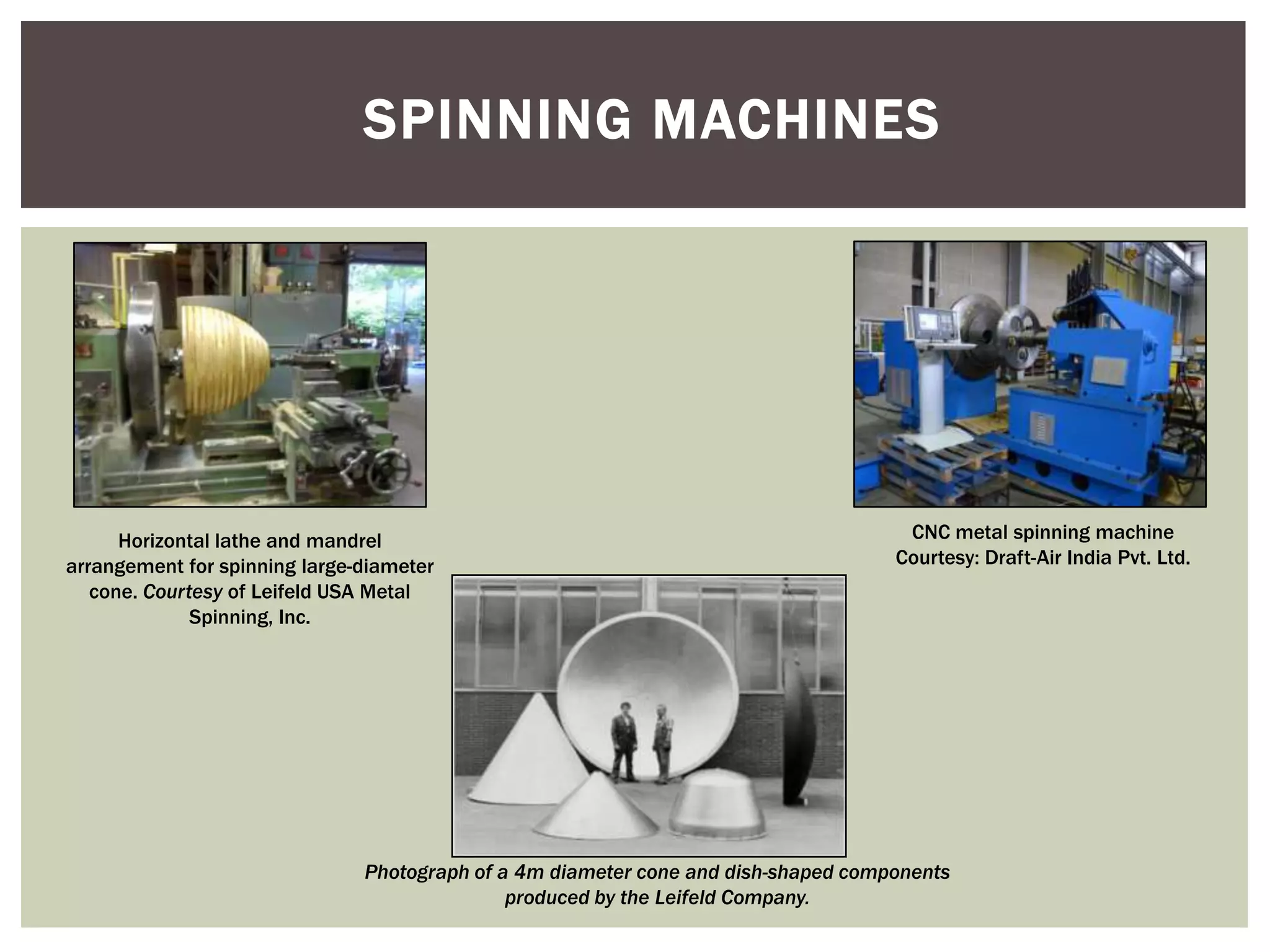

The document provides an overview of the metal spinning process. It discusses the history and classification of different metal spinning techniques. The basic metal spinning process involves clamping a metal blank between a spinning mandrel and follower, and using specially designed tools to form the blank into an axially symmetric product while it rotates at high speeds. Key aspects covered include the mechanics of cone spinning, use of multi-pass spinning for small cone angles, mandrel and tool design, lubricants, common spinning machines, advantages over other forming processes, and applications.