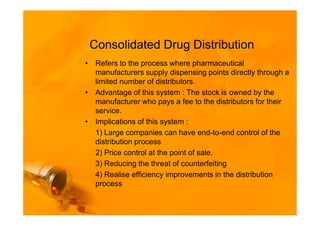

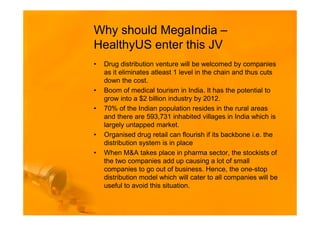

The document discusses plans for a joint venture between MegaIndia and HealthyUS to establish a consolidated drug distribution system in India. Key points include:

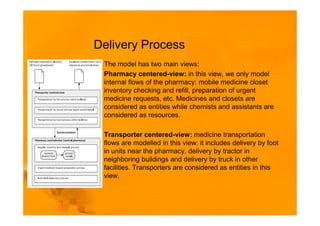

1) The venture would eliminate intermediaries to cut costs and have end-to-end control of distribution.

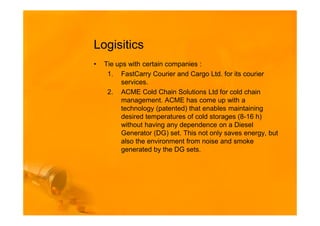

2) Rural India is an untapped market that could be served through various transport methods like trucks, carts, and on foot.

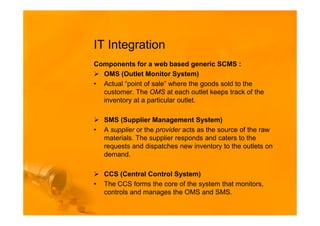

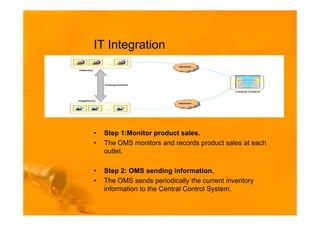

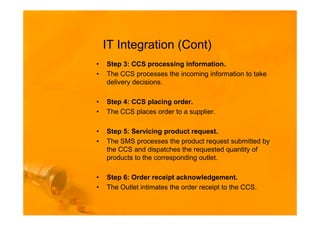

3) An IT system would monitor inventory levels and place orders to maintain supply at outlets.