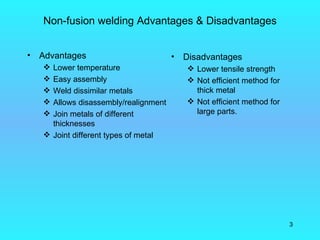

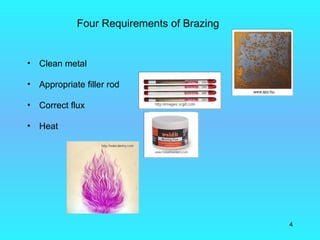

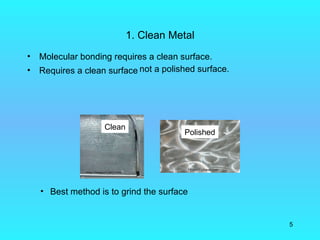

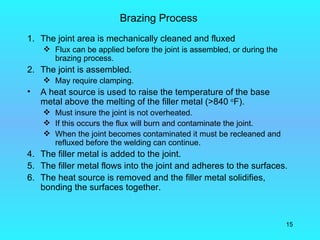

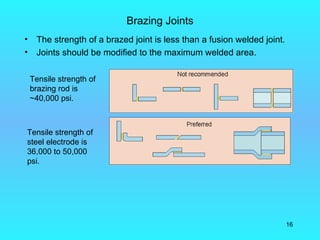

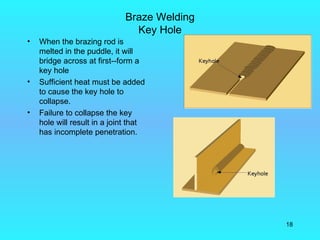

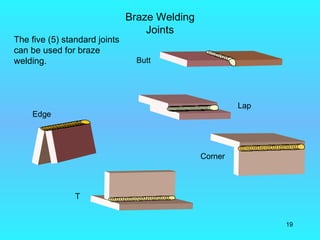

This document discusses brazing, braze welding, and soldering processes. Brazing uses filler metals that melt above 840°F and relies on capillary action to draw the filler into the joint. It requires clean surfaces, the correct flux, and heating above the filler metal's melting point. Braze welding is similar but forms a visible bead instead of relying on capillary action. Both produce stronger joints than soldering, which uses filler metals below 840°F. Key requirements for brazing and braze welding include cleaning the joint area, using the proper filler and flux, and carefully controlling heat to melt the filler without burning the flux.