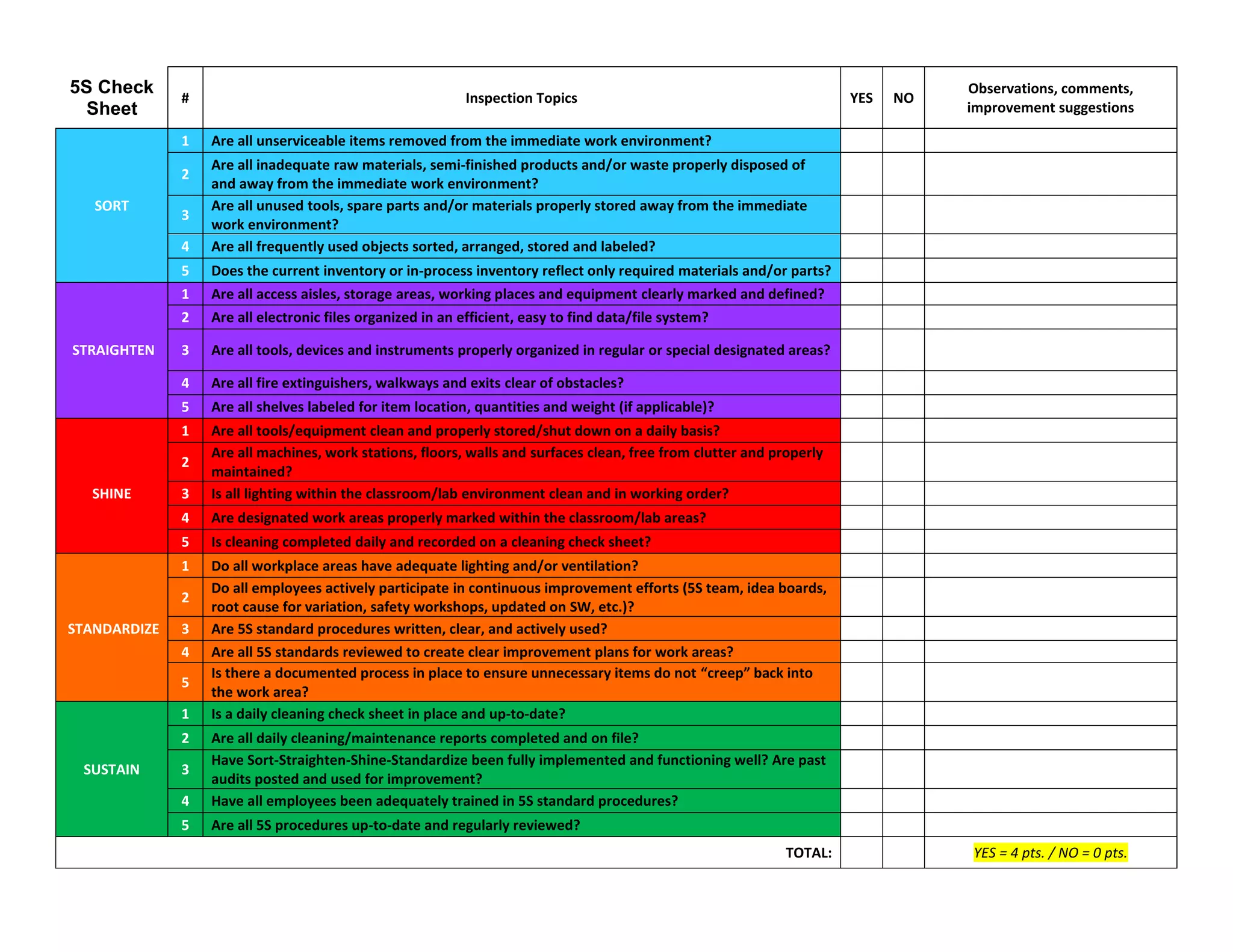

This document contains a checklist for conducting a 5S audit of a workspace. The checklist is divided into the five sections of 5S: Sort, Straighten, Shine, Standardize, and Sustain. Each section contains 5 items to check for compliance with 5S standards for an organized, clean, and well-maintained workspace. An overall score is calculated based on marking Yes or No for each item.