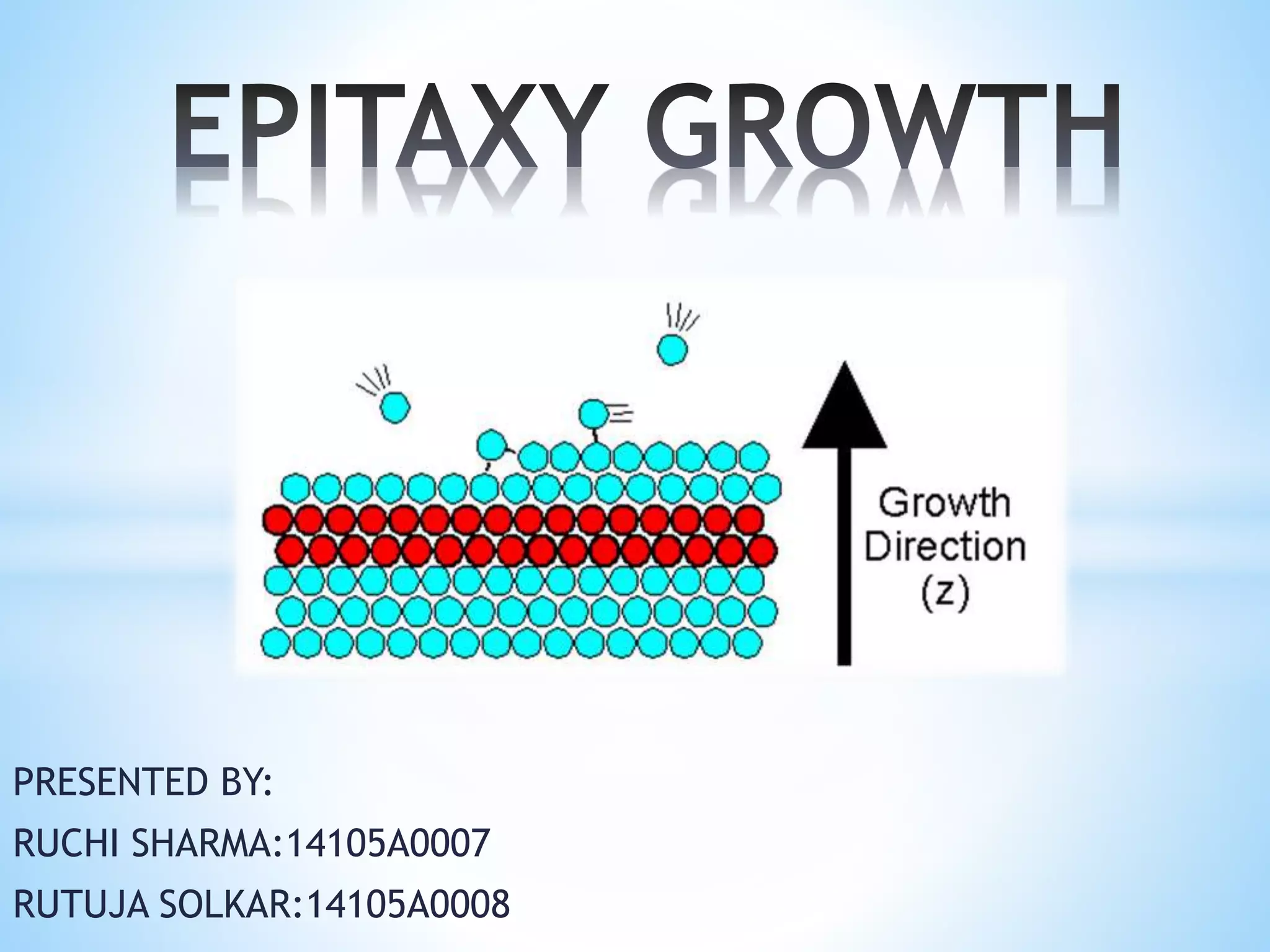

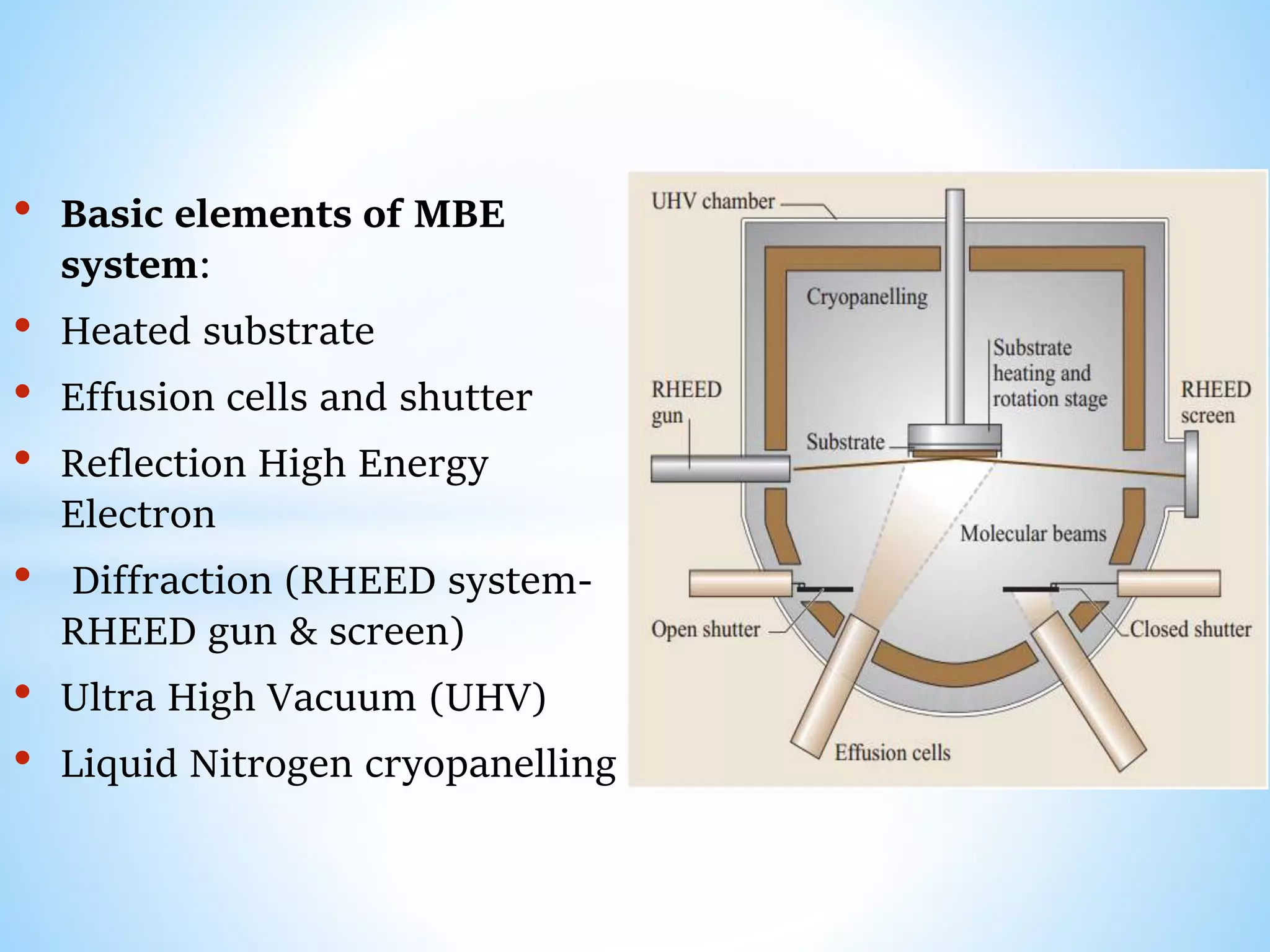

Epitaxy is the process of depositing a mono-crystalline film on a mono-crystalline substrate, classified into homoepitaxy, heteroepitaxy, and their pseudo variants. Various methods such as liquid phase epitaxy and molecular beam epitaxy are utilized for this process, each offering specific advantages like high growth rates and controlled film thickness, while also presenting limitations such as reproducibility issues and high costs. Applications include semiconductor fabrication, nanotechnology, and producing high-quality crystal layers.