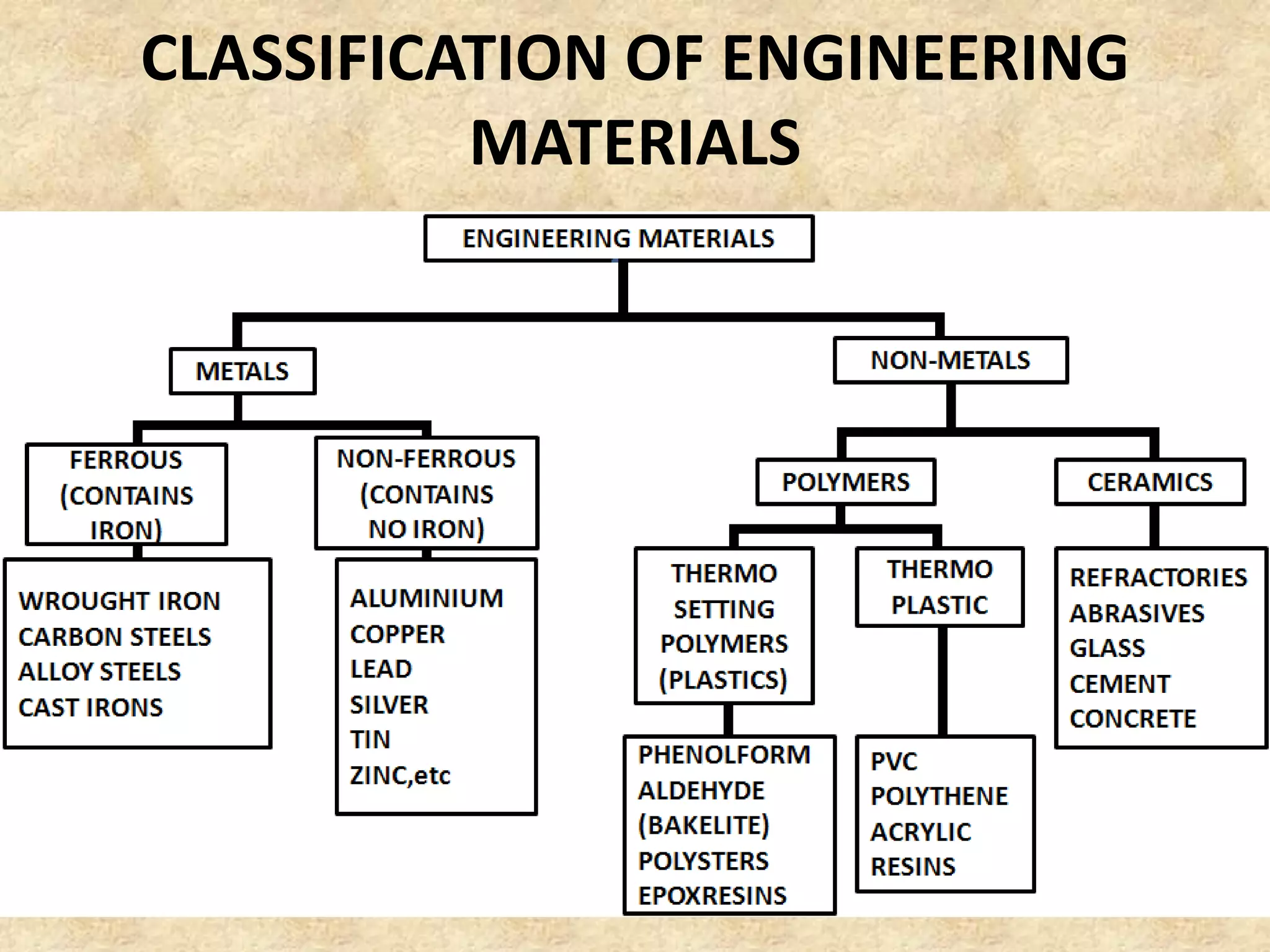

The document discusses engineering materials and their properties. It defines engineering materials as substances useful in engineering fields. Material selection considers properties like mechanical, physical and chemical properties, as well as cost, availability, durability and appearance. Mechanical properties discussed include strength, stiffness, elasticity, plasticity, ductility, malleability, toughness and hardness. Common types of strength are tensile, compressive and shear strengths.