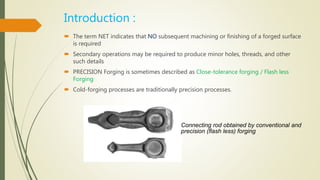

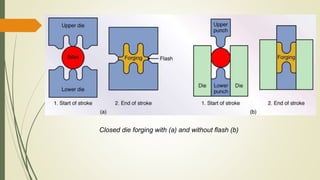

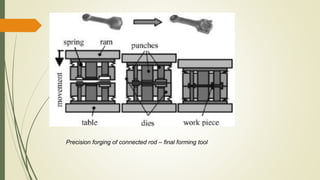

The net shape forging process eliminates the need for subsequent machining of forged surfaces and requires precision tooling with careful consideration of die wear and preform quality. Advantages include reduced material waste and superior mechanical properties, though initial costs may be higher compared to traditional forging methods. Proper lubrication control and process setup are critical for achieving desired tolerances and product quality.