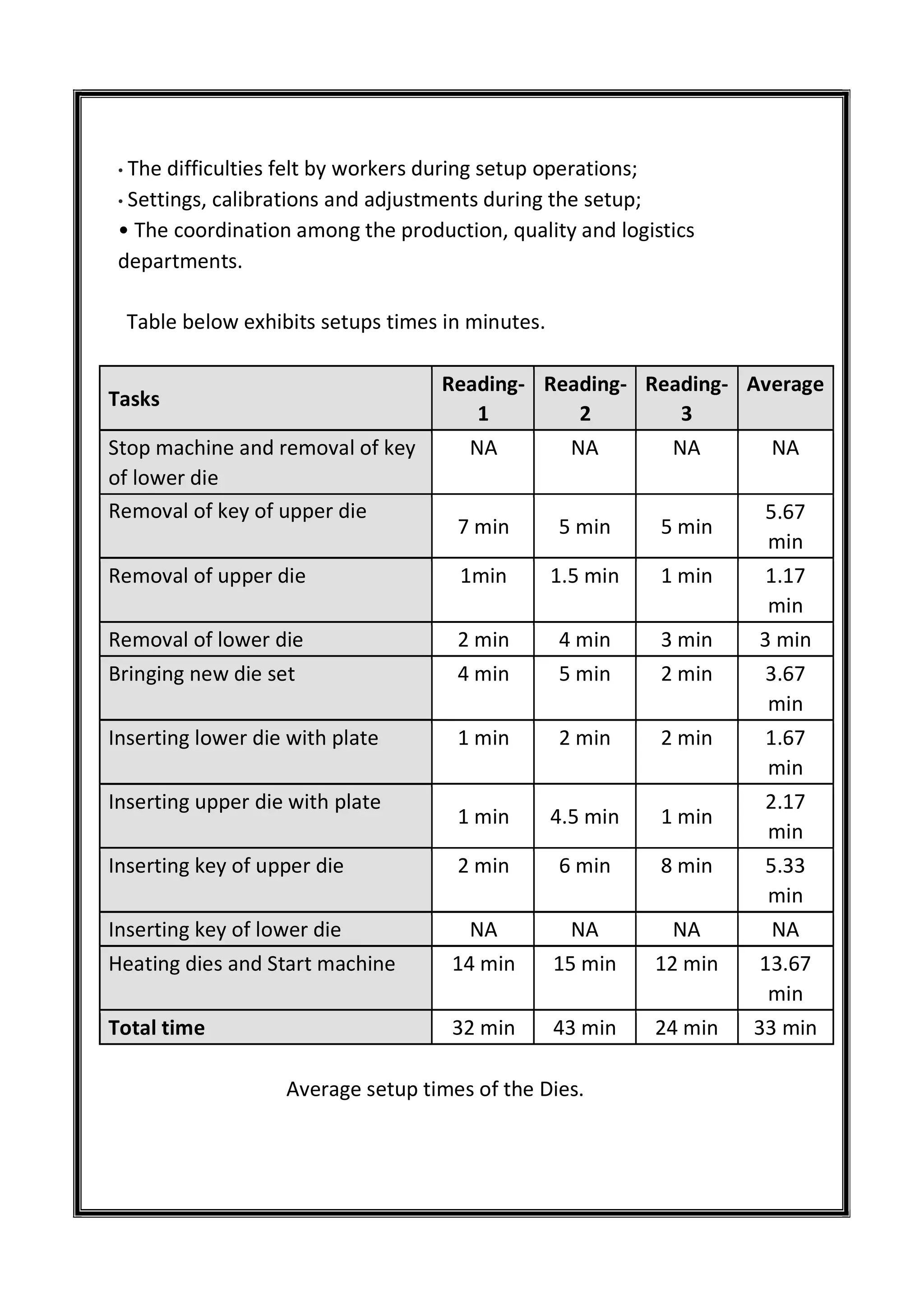

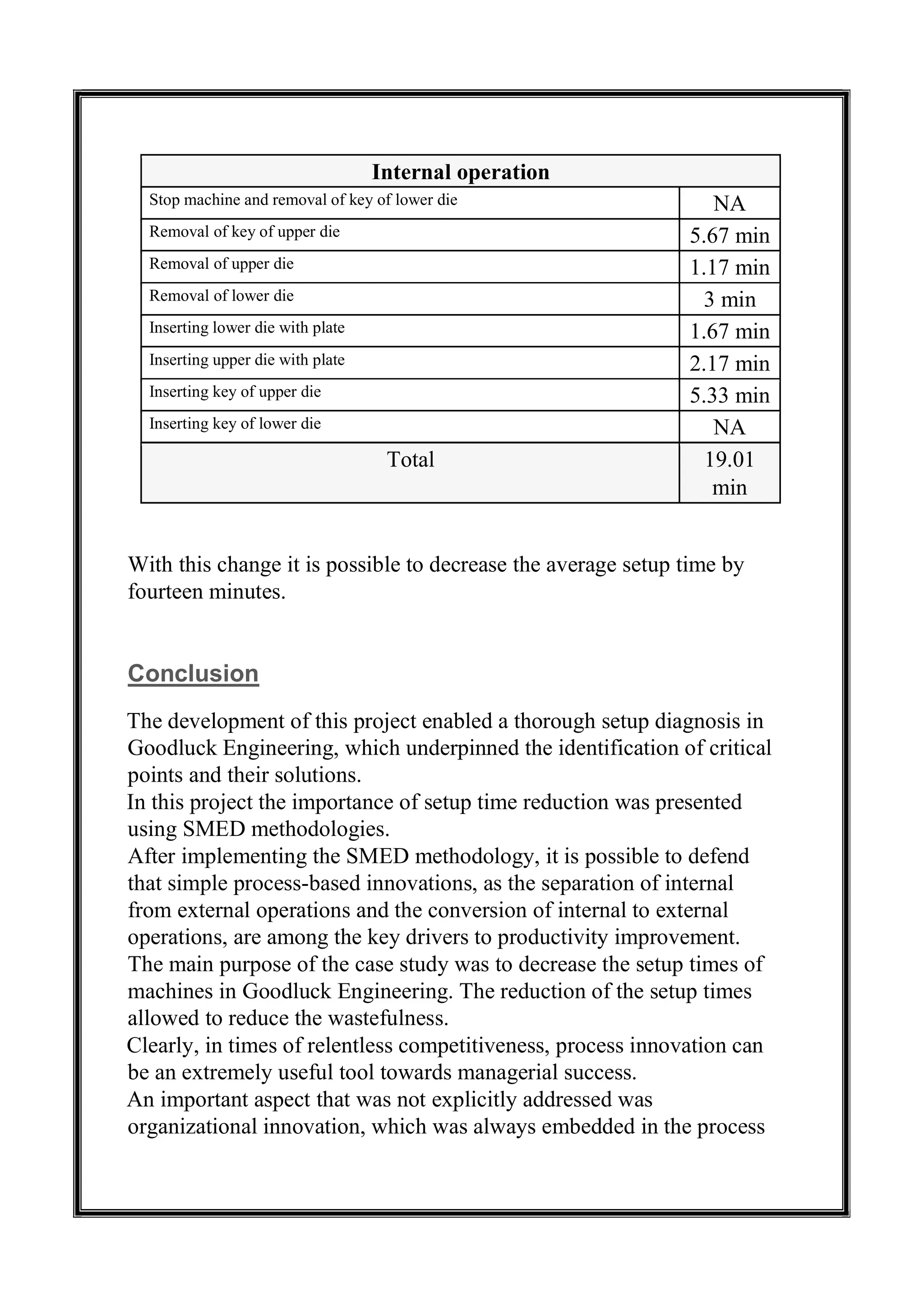

This industrial training report discusses single minute exchange of die (SMED) in closed die forging. It provides an overview of Good Luck Engineering Co., which manufactures open and closed die steel forgings. The report describes the forging process, including cold forging, warm forging, and hot forging. It also discusses closed die forging and open die forging techniques and the key steps in the forging process, including die preparation, lubrication, and multi-step forming. The goal of the report is to analyze SMED techniques that can reduce die changeover times in closed die forging.