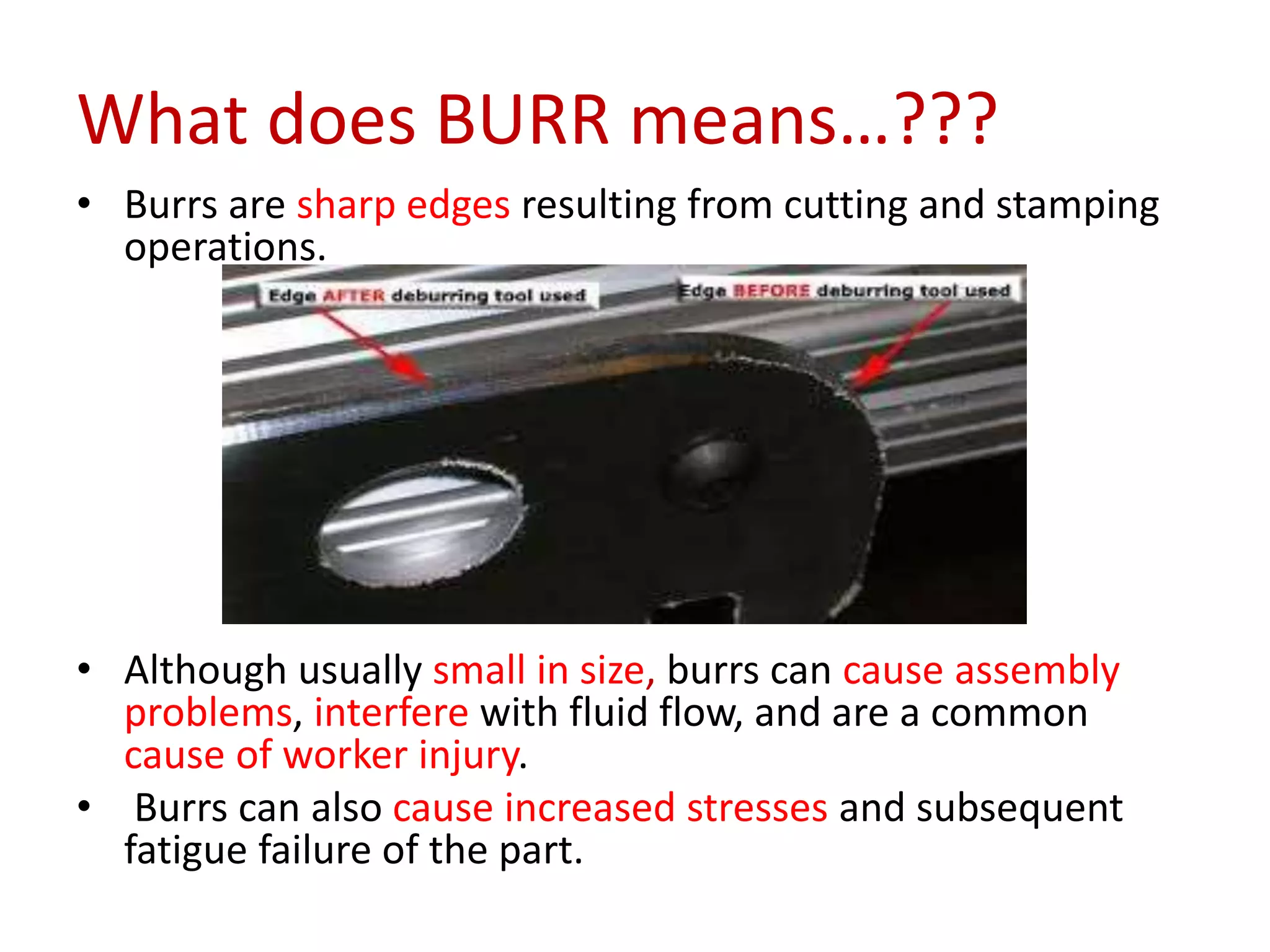

This document discusses deburring processes. It defines burrs as sharp edges created during cutting and stamping operations that can cause assembly and safety issues. Deburring is the process of removing burrs, typically through filing, sanding, or newer techniques. The document outlines several common mechanical deburring processes like cutting, power brushing, bonded abrasives, mass finishing and abrasive blasting. It also discusses less common thermal deburring using heat and electro-chemical deburring which dissolves burrs using electrolysis. The goal of deburring is to prepare metal or wood surfaces for further finishing or assembly.

![Mechanical Deburring Processes

Mechanical deburring encompasses many types

of processes, including:

1] cutting processes

2] power brushing

3]bonded abrasive finishing

4] mass finishing

5] abrasive blasting

6]abrasive flow deburring](https://image.slidesharecdn.com/deburringprocesses-171120121756/75/Deburring-processes-5-2048.jpg)

![1] Cutting Processes

Cutting processes encompass a variety of manual and mechanized

cutting tools for deburring, such as:

• drills

• reamers

• rotary and flat files

• knives and scrapers

• brushes and stones

• bonded abrasive papers, belts and wheels

• mechanical edgers

• numerically controlled machining centers with deburring tools](https://image.slidesharecdn.com/deburringprocesses-171120121756/75/Deburring-processes-6-2048.jpg)

![2] Power Brushing

• Power brushing is both a fast and relatively low cost

deburring method.

• Brushes are made of metal filaments or wire and

may also be of non-metallic or synthetic materials.

•](https://image.slidesharecdn.com/deburringprocesses-171120121756/75/Deburring-processes-8-2048.jpg)

![3] Bonded Abrasive Finishing

• Bonded abrasive finishing, also known as

sanding, is found in most manufacturing

facilities. Bonded abrasive products include

sheets, belts, pads, disks, and wheels.

• The most common abrasives used include

aluminum oxides, silicon carbide, or zirconia

compounds.

• These abrasives range in size and grade from

course to exceptionally fine for various

applications](https://image.slidesharecdn.com/deburringprocesses-171120121756/75/Deburring-processes-10-2048.jpg)

![4] Mass Finishing

• Mass finishing allows for the mechanical finishing of many parts

simultaneously.

• In addition to deburring, mass finishing may also be used to

descale, brighten, and polish parts.](https://image.slidesharecdn.com/deburringprocesses-171120121756/75/Deburring-processes-11-2048.jpg)

![5] Abrasive Blasting

• Abrasive blasting can be done either wet or

dry

• The stream of abrasive material, propelled by

air pressure, can be focused on a specific area

or applied fan-like to an entire part or part

surface.](https://image.slidesharecdn.com/deburringprocesses-171120121756/75/Deburring-processes-13-2048.jpg)

![6] Abrasive Flow Deburring

• Abrasive flow deburring involves the extrusion of

semi-solid material impregnated with abrasives

through holes and openings in hydraulically

clamped workpieces.

• Extrusion pressure can range from 100 to 3200

PSI.

• The most common abrasive media used is silicon

carbide in a polymer carrier.

• Other abrasives include boron carbide, alumina,

and diamond](https://image.slidesharecdn.com/deburringprocesses-171120121756/75/Deburring-processes-15-2048.jpg)