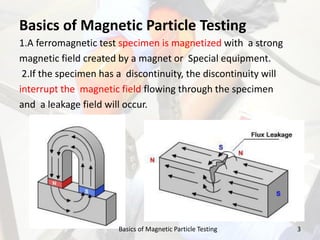

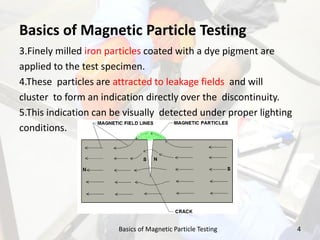

This document provides an overview of magnetic particle testing (MPT). MPT can detect both manufacturing defects and in-service damage in ferromagnetic materials. The basics involve magnetizing a test specimen, which causes discontinuities to distort the magnetic field and produce indications. Iron particles coated with dye are applied and cluster at these indications. The procedure involves pre-cleaning, magnetizing the specimen, applying particles, and interpreting any visible indications of discontinuities. MPT can be done with dry or wet particles and produces indications of cracks and defects.