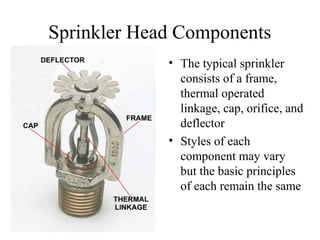

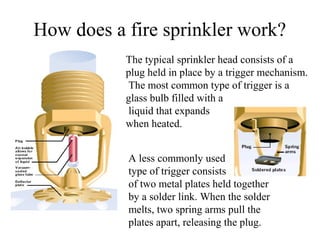

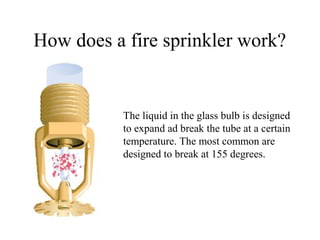

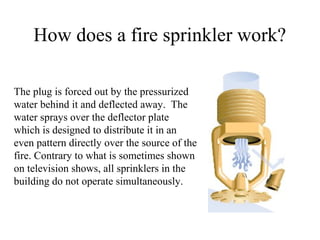

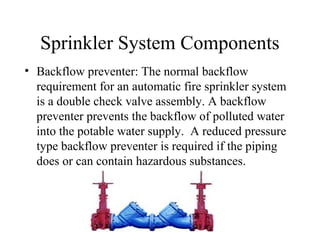

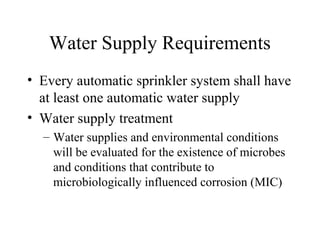

This document summarizes different types of fire sprinkler systems and their components. It discusses how sprinklers work to suppress fires, noting that individual sprinkler heads activate independently when heated to a certain temperature by a fire. The document outlines the key components of sprinkler systems, including sprinkler heads, piping, a water source, and typically an alarm and control valves. It also summarizes different types of sprinkler systems like wet pipe, dry pipe, deluge, and pre-action systems and how they differ in components and fire detection/suppression operation.