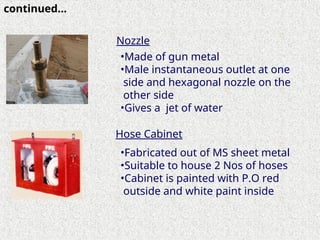

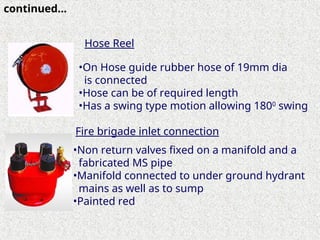

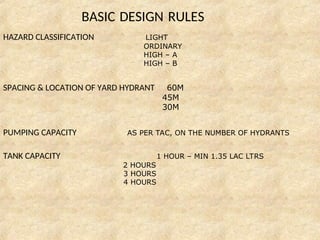

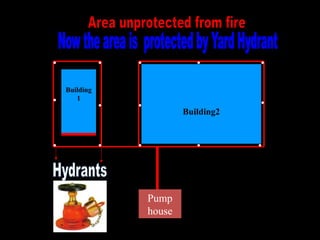

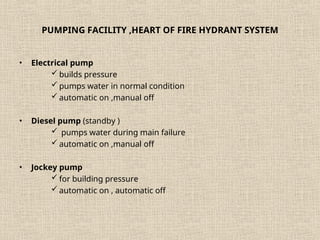

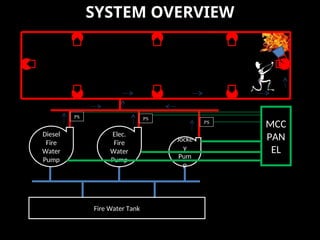

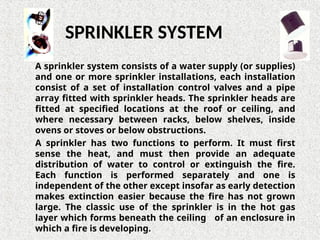

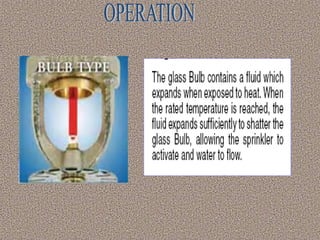

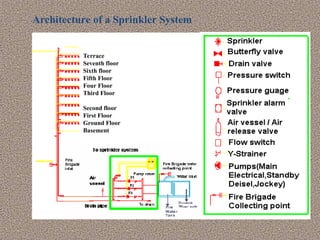

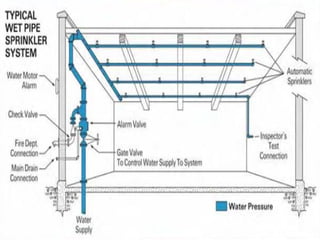

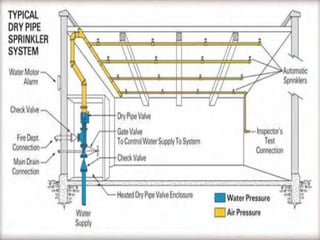

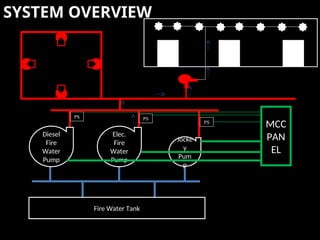

The document outlines the components and functions of fire hydrant and sprinkler systems, detailing their design and operational requirements. It discusses the types of hydrants, hoses, nozzles, and the various sprinkler system types including dry-pipe and wet-pipe systems. Additionally, it mentions the importance of adequate water supply and pressure maintenance for effective fire suppression.