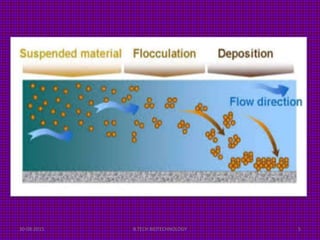

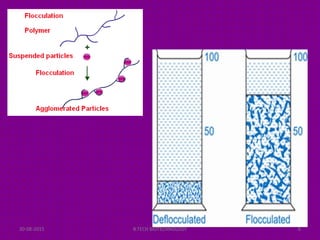

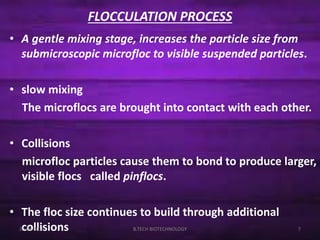

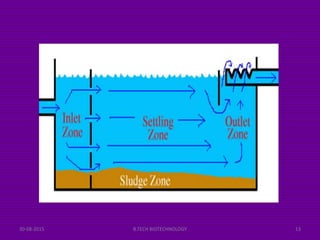

Flocculation and sedimentation are processes used to separate suspended solids from water. Flocculation involves the addition of chemicals to destabilize particles and cause them to cluster together into larger flocs. Careful control of mixing is needed to build up floc size without shredding. Sedimentation allows flocs to settle out of solution by gravity in tanks with distinct zones. The type of sedimentation depends on factors like particle settling behavior and concentration. Together, flocculation and sedimentation are important steps in water and wastewater treatment.