Site specific safety plan dib

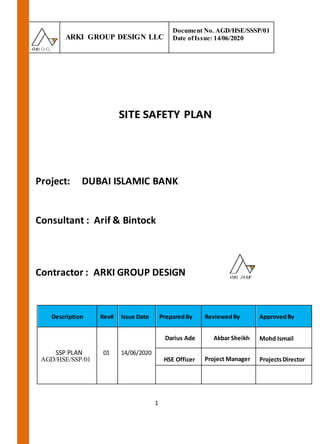

- 1. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 1 SITE SAFETY PLAN Project: DUBAI ISLAMIC BANK Consultant : Arif & Bintock Contractor : ARKI GROUP DESIGN Description Rev# Issue Date PreparedBy ReviewedBy ApprovedBy SSP PLAN AGD/HSE/SSP/01 01 14/06/2020 Darius Ade Akbar Sheikh Mohd Ismail HSE Officer Project Manager ProjectsDirector

- 2. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 2 TABLE OF CONTENTS 1. EHS Regulations. 1.1 - Legislation 1.2 - Code of Practice. 2. Safety Objective 3. Site Specific Safety Plan 3.1- Responsibility/Key Line Personnel 3.2 -Scope of Work Evaluation 3.3 -Hazard/Risk/Exposure Assessment 3.4- Control Measures 3.5- Periodic Inspections 3.6- Daily Safety Planner 3.7- Compliance 3.8- Written Progressive Disciplinary Program 3.9- Hazard Correction 3.10- Training and Instruction 3.11- Project Site Orientation 3.12- Employee Communication System 3.13- Record Keeping 3.14- Accident/ Exposure Investigation 3.15- Emergency Action Plan 3.16- Site-specificMedical Emergency Plan 3.17- Hazard Communication Plan 3.18- Waste Management 4. APPENDIX –B (Inspection Forms) 4.1 – Daily Inspection Form 4.2 – Weekly Inspection From 4.3 – Accident/Incident Investigation Form 4.4 – Incident / Accident Record Form 5. Organization Chart. 5.1 – Project Flow Chart – (Attached) 5.2 – HSE Flow Chart

- 3. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 3 6. Attachments 6.1 - Risk Assessment

- 4. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 4

- 6. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 6

- 7. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 7 . l ti . . i l ti f r ti . . t r f r ti 1. EHS Regulation. The Contractor is an Employer of labour and must comply with all Ministerial orders, laws and contractual regulations relating to site natural environment, occupational health and safety legislation and in particular with the following. Dubai Municipality code of construction safety practice UAE—Labour Law-Federal lawNo: 8 of 1980 Ministerial order No: 32 for the year 1982 Federal law No: 24 of 1999-for the protection and development of environment Local Order No: 61 of 1991-Dubai Municipality Technical guidelines of Dubai Municipality 1.1 DUBAI Legislation and Codes Of Practice. The contractor must comply with all other Health, Safety and Environmental Legislation. Dubai Municipality health & safety construction codes of practice manual; Dubai regulation for Electrical installation -1980; Department of Occupational Health Regulations; General Authority for Health Service Guidelines; Environmental Agency, Abu Dhabi; Dubai water and Electricity Authority (DEWA) inspection regulation; National Building code/Guidelines; Safety Guidelines pertaining to Petroleum Products and Explosives; Guidelines of Abu Dhabi Urban Planning council. 1.2 DUBAI Codes of Practice. Hazardous Materials Personal Protective Equipment First Aid and Medical Treatment Emergency Management Requirements

- 8. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 8 - T TI Fire Prevention, Planning and Control Manual Handling and Ergonomics Electrical Safety Control of Major Accident Hazards (COMAH) Safety Signage and Signals Permit to Work Systems Working at Heights Scaffolding Hot Work Operations (Welding and Cutting) Portable Power Tools Ladders Waste Management 2 - SAFETY OBJECTIVE The Company that is committed to protecting employees, clients and the general public on all our projects. This premise is a Company value of great importance. Our goal is ZERO incidents. The following guiding principals will evidence this philosophy and our future success:- Senior management is responsible to support and monitor the safety, health and risk management process. The line organization is responsible and accountable to lead and implement the safety, health and risk management process. Supervision shall possess the skills and commensurate with project responsibilities. All employees must comply with safety, health, and risk management requirements. We will work towards continuous improvement.

- 9. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 9 . T ri t f ll i l t : . . I I IT I TI I TI I We will foster a culture that aligns safety, health and risk management with the other business objectives. The emphasis will be on the Safety, Health and Risk Management. Planning process and reduction of incidents will be our measure of our success. 3. The SSSP Comprises the following elements: 1. Responsibility/Key Line Personnel 2 . Scope of Work Evaluation 3. Hazard/Risk/Exposure Assessment 4. Control Measures 5. Periodic Inspections 6. Daily Safety Planner 7. Compliance 8. Written Progressive Disciplinary Program 9. Hazard Correction 10. Training and Instruction 11. Project Site Orientation 12. Employee Communication System 13. Record Keeping 14. Accident/ Exposure Investigation 15. Emergency Action Plan 16. Site-specific Medical Emergency Plan 17. Hazard Communication Plan 18. Waste Management 3.1. RESPONSIBILITY / IDENTIFICATION OF KEY LINE PERSONNEL Project Manager Project Engineer EHS Manager

- 10. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 10 Quantity Surveyor Safety Officer Site Supervisors Logistics In Charge The above noted personnel have the authority for implementing the provisions of this program. All managers and supervisors are responsible for implementing and maintaining the SSSP Program in their work areas and for answering worker questions about the SSP Program. A copy of this SSSP Program is available from each manager and supervisor. Project Manager The Project Manager and is responsible for the operational planning and also the implementation of safety at site. He shall be familiar with all relevant health and safety legislation. Heshall ensure that all staff accountabletohimis conversant with the relevantrequirements of current legislation and the Site HSE Plan. He shall ensure that each Section Engineer has adequate resources to carry out his duties and responsibilities in accordance with the Site HSE Plan. He shall establish and maintain a direct line of communication with the Safety Officer. He shall be the Emergency Co-ordinator with listed duties. He shall monitorthe siteoperationto ensure they are conductedin accordancewiththe Site HSE Management Plan and take urgent and appropriateaction to prevent unsafe working practices or other infringements of statutory of the safety plan requirements. He shall ensure that all subcontractors comply with the requirements of the Site Specific Safety Plan. He shall ensure those all-necessary work procedures, method statements and work instructions are prepared and issued for safe operation of the works on site. Project Engineer

- 11. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 11 It is the responsibility of the site Engineer to arrange sufficient manpower to unload/load the material using safe manual handling technique and take the materials to the work location without making any inconvenience to the visitor/staffs. Logistics In Charge It is the duty of the Logistics In Charge to coordinate with Project Manager/Construction Manager/Project Engineer for smooth functioning of Logistics activities in site operations. Site Engineer will assist him to receiving materials from various suppliers and sub- contractors and shifting to proposed storage area. Maintain proper records of the materials inventory; ensure storage as per the prescribed storage conditions and to ensure timely deliveries to the customers. Ensure training of employees in the related areas and maintain the departmental policies and procedures in a positive way. Ensure health and safety procedures of the Company in order to maintain a safe working environment. Ensure to effectively maintain minimum stock level at all times. Ensure effective and efficient delivery of the products to the customers as per the commitments. Plan, schedule and control outgoing materials effectively and efficiently. Perform relevant duties and responsibilities, assigned from time to time, by the immediate superior. Site Supervisor They shall be familiar with all safety procedures relating to the work being carried out under their supervision. They shall ensure that theirsubordinatesreceiveclearsafetyinstructions relatingtothe work that they are carrying out

- 12. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 12 They shall ensure that the workplace is maintained in a safe and tidy condition They shall assist in giving toolbox talks. They shall take prompt action to rectify unsafe conditions. They shall give full co-operation to the Site Safety Officer and comply with his recommendations They shall ensure that all necessary safety devices are provided and used, all site personnel under their control areprovidewith andwear the necessary Personnel ProtectiveEquipment (PPE), and that all safety procedures appertaining to the works are complied with. They shall carry out regular inspections of the workplace. They shall be familiar with all Emergencies and Accident Reporting Procedures ensure that they are known to their subordinated, and implement those procedures as required. They shall promote safety awareness through leading by example. They shall ensure that all newoperativesunder their control have receivedinductiontraining before commencing work. Site Supervisorwill assist the site engineer in taking the material tothe concernedwork area in a proper and safe means and proper storage of the material to be arranged. HSE Manager. The HSE Manager shall be appointed in writing, accountable to the Project Director for the safety assurance of the construction and the supervision and monitoring of the Site HSE Management System. He shall be empowered to stop immediately any work activity on the project and instruct employeesof the Company or any subcontractor to take urgent actionto makesafe the Site and Works to prevent unsafe working practices or other infringements of the Site HSE Management Plan or statutory regulations. He shall advise management on: -

- 13. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 13 Preventing injury to personnel and damage to plant and equipment. To further improve safe working methods. Ensuring Legal requirements affecting safety, health and welfare are being adhered too.. Monitoring the provision and use of protective clothing. Train & assist identifying potential hazards beforework starts. Evaluate and implement methods of safe working arising from new developments. Train & induct management and employees about changes in legislation and codes of practice. He shall carry out, or direct the Site Safety Supervisors to carry out, safety inspections in associationwithsite staff to ensure those safemethods of work are beingobserved.He shall personally carry out weekly inspections of all work areas. He shall report the findings to the Section Engineer and recommend what measure, if any are required to be taken as a result of the inspection. In the event of these measures not being adopted he shall bring the matter to the attention of the Project Manager/Director. He shall ensure that daily safety monitoring is maintained and shall keep a daily. He shall determine the cause of any accident or dangerous occurrence and recommend means of preventing recurrence. For serious accidents he will form part of the accident investigation team as required by the Safety Management. He shall supervise the recording and analysis of information on injuries, damage and loss, assess accident trends and review overall safety performances. Heshall check all Work Proceduresand Method Statementsbeforethey areissued to ensure that safety aspects of the operations they cover are in accordance with the requirements of the Site Specific Safety Plan He shall prepare and submit to the Project Manager a report on or before the last day of every month.

- 14. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 14 He shall issue Non-conformance Reports for serious irregularities observed on site. HSE Officer HSE Officer will ensure that a permit work is in place for all deliveries and all operatives are following the safe handling techniques and frequently monitoring all activities. Safety Officer shall be responsible to the Safety Manager as well as the Section Engineer of the section to which they have been assigned. He shall arrange induction safety training as is required. He shall liase with subcontractors and foremen to ensure they observe the safety standards required under the Site Specific Safety Plan. He shall assist with the safety aspects of risk assessments and planning duties as required by the Section Agent or Safety Officer. He shall assist with the promotion of safety on site. He shall carry out daily field inspections and review findings with supervisors and follow-up on corrective action taken All Personnel Every person employed on the Project has a statutory duty to take reasonable care for the health and safety of themselves and others that may be affected by their actions or omissions at work. With regard to the statutory duties imposed on their employer, they must co-operate with their employer to enable him to comply with the relevant statutory provisions No person shall intentionally or recklessly interfere with or misuse anything provided for safety, health or welfare under the relevant statutory provisions All personnel shall wear or use the appropriate safety equipment or clothing and use the appropriate safety devices

- 15. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 15 . . T I . I T All personnel shall familiarise themselves with the relevant requirements of the Site HSE Management Plan and the appropriate requirements of specific safety plans All personnel shall report any accidents and damage to property or equipment to their immediate supervisor, irrespectiveof whether persons are injured All personnel are encouraged to make suggestions to improve health and safety to their supervisor and the Safety Officer. 3.2. SCOPE OF WORK EVALUATION Description of work to be performed as Listed below. Interior Fit-Out Works:- Joinery. MEP – Lights/HVAC/ IT/ Fire Fighting Works Gypsum Partition Steel Structure Frame Work Painting Floor Tile Work. Corian Works etc 3.3. HAZARD/RISK/EXPOSURE ASSESSMENT To establish a procedure to identify the hazards present, assess risks involved and identify the controls and precautions to carry out the work in a safe manner. The major safety hazards/risks and exposures have been assessed as follows:- Falling objects Working @ Height- Scaffolding Ladder/climbing Power Tools Manual Handling. M&E Installation. Steel Frame Erection.

- 16. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 16 Slip trip and falls Temporary electrical installations Hazard : A source or situation with the potential of harm in terms of human injury or ill health, damage to property, damage to the environment or a combination of these. Risk: The combination of the likelihood and consequence(s) of a specified hazardous event occurring. PM: Management Representative. Risk Assessment: The overall process of estimating the magnitude of risk and deciding whether or not the risk is tolerable or acceptable. RESPONSIBILITY The Safety Manager /Safety Officer/ Site Supervisor is responsible for the overall implementation of this procedure, as well as verifies the completion of the task as per stipulated requirements. PROCEDURES The Safety Officer conducts risk assessments using Risk Assessment Record in coordination with the PM. The assessment identifies the hazards that could reasonable cause harm and must take into account during investigation, ill health, human behaviour, damage and injury when compiling the initial data for identifying the level of risk. The assessment includes routine/non-routine activities in arki personnel, subcontractors, visitors and facilities at the work place and all the related sites. Identify the personnel fully/partially involved in each activity and are affected on occurrence of this hazard.All accidentrelatedactivitiespertinentto the same arehandled as per Accident/Incident Investigation and Reporting procedure The significance of a risk shall be assessed based on the Severity and Probability.

- 17. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 17 tr l l The risks related to legislation are considered significant. All risks having high potential shall be considered as significant risks. The high risks identified are considered while setting of goals and objectives for Arki. The goals and objectives shall be reviewed at least once a year during Management Review Meetings. A Management Program is developed for each goal and objective. TheManagement Programdescribesthe method of achieving the setgoals and objectives including the time scales and the personnel responsible for implementation of these tasks. These programs shall be documented and monitored for continual improvement. The Risk Assessment Record shall be reviewed to ascertain, if the assessment is still relevant, dependent on:- Changes in the nature of work process. Change in legislation. Near Miss incidents. Annual basis. Injury. Control Plan Steps 1 – 7 Stage 1 Hazard Identification Stage 2 Risk Assessment Stage 3 Risk Control

- 18. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 18 1 Identify sources of hazard and their causes. 2 Analyze how and whythe hazard could occur. 3 Analyze the consequences of the risks. 4 Consider likelihood of the hazard and estimate the risk. 5 Judge the acceptability of the risk. 6 Decide risk controloptions and implement selected controls. 7 Monitor riskcontroloptions. The risk assessments carried out for operational activities shall be reviewedonce yearly or on changes to operational conditions. Daily the Safety Officer carries out checks against a Checklist and records are maintained. In case of any problem observed, actions are initiated in consultation with PM. 3.4 CONTROL MEASURES Site staff will monitor the hazards/risks and exposures in accordance with this Safety Plan. The plan addresses the various hazards/risks and exposures, and the checklists and will bring any concerns or violations to the attention of the staff for correction. Unsafe or unhealthy work conditions; practices or procedures shall be corrected in a timely manner based on the severity of the hazard. Minimum required protective equipment (PPE) would be: Hard hats Eye protection Safety boots Hi Vis Vest Gloves Fall Protection Hard hats Hearing protection Personnel Protective Equipment

- 19. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 19 r l ill tr i i t r r li ti f . Personnel protection is essential to reduce human exposure to potential hazards associated with work, which cannot be practicably controlledat source. All employees will wear the correct “personnel protective equipment” – PPE’s, at all times. PPE include hard hats (helmets), safety shoes, High Visibility Vest, safety goggles, dust masks and other masks necessary for protection from hazardous exposures. Worn out or defective PPE will be replaced immediately. Personnel who wilfully disregard these regulations, or tamper with PPE to reduce its effectiveness will be subjected to disciplinary action. Immediate supervisor and or Safety Officer will instruct their personnel in the correct application of PPE issued to them and will ensure that they are being used. The use of safety helmet on site is a mandatory except in designated areas such as office & canteens. All helmet shall bear the company logo or name of ARKI on the front and back. Helmet color code to be followed. Consultant/ Engineers/Supervisors/Forman – White Helmet Safety Staff:- White Helmet with Red Circular Sticker with HSE written. Workers/Craftsmen & Banksmen – Blue Helmet The Safety officer will ensure that stock of standard PPE items and other safety equipment are ordered on time and in line with the minimum / maximum levels set for each item. Personnel will be trainedin the proper use and application of PPE. 3.5. PERIODIC INSPECTIONS Safety inspections will be performed weekly by the Site Safety Engineer. The inspection will check for hazards and unsafe practices or conditions and this will be recorded on ‘General Inspection Report’. Any safety hazards which could not be corrected at the time of the inspection will be notified to the Project Manager for further action. Periodic inspections will be performedaccording to the following schedule:

- 20. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 20 • When new substances, processes, procedures or equipment, which present potential new hazards, are introduced into our workplace. • When new previously unidentified hazards are recognized. • When Occupational injuries and illnesses occur • When we hire and/or reassign permanent or intermittent workers to process, operations, or tasks for which a hazard evaluation has not been previously conducted; and • Whenever workplace conditions warrant an inspection. • Periodic inspection consists of identification and evaluation of work place hazards utilizing applicable sections of the Hazard Assessment the Daily Safety planner system any other effective methods to identify and evaluate work place hazards 3.6. DAILY SAFETY PLANNER The Daily safety planner method will be utilized to identify work place hazards. A sample Daily safety Planner is included in Appendix A. This is a daily check list that all site staff is required to review on a daily basis. The project engineer and client representatives should be immediately notifiedof any potential safety issues. 3.7. COMPLIANCE REQUIREMENTS Management is responsible for ensuring that all safety and health polices and procedures are clearly communicated and understood by all employees. Managers and supervisors are expected to enforce the rules fairly and uniformly. All employees are responsible for using safe work practices, for following all directives, policies and procedures, and for assisting in maintaining a safe work environment. Our system of ensuring that all workers comply with the rules and maintain a safe work environment includes: - Informing workers of the provisions of our SSP Program Evaluating the safety performances of all workers Recognizing employees who perform safe and healthful practices Providing training to workers whose safety performance is deficient Disciplining workers for failure to comply with safe and healthful practices.

- 21. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 21 3.8. WRITTEN PROGRESSIVE DISCIPLINARY PROGRAM Non-compliance with Site Safety rules and regulation will result in disciplinary action provided for in the corporate discipline program. 3.9 HAZARD CORRECTION Unsafe or unhealthy work conditions; practices or procedures shall be corrected in a timely manner based on the severity of the hazards. Hazards shall be corrected according to the following procedures: - When observed or discovered. When an imminent hazard exist which cannot be immediately abated without endangering employee(s) and/or property, we will remove all exposed workers form the area except those necessary to correct the existing condition. Workers necessary to correct the hazardous condition shall be provided with the necessary protection: and All such actions taken and dates they are completed shall be documentedon the appropriate forms. 3.10 TRAINING AND INSTRUCTION All workers, including managers and supervisors, shall have training and instruction on general and job-specific safety and health practices. Training and instruction shall be provided as follows:- • When the SSSP Program is first established • To all new workers •To all workers given new job assignments for which training has not previously been provided •Whenever new substances, process, procedures or equipment are introduced to the workplace and represent a new hazard •Whenever the employer is made aware of a new or previously unrecognized hazard •To supervisors to familiarize them with the safety and health hazards to which workers under their immediate direction and control may be exposed; and •To all workers with respect to hazards specific to each employee's job assignment.

- 22. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 22 Workplace safety and health practices for all locations include, but are not limited to, the following:- •Explanation of the SSSP Program, Contractor's/Client's Safety Program, emergency action plan and fire prevention plan, and measures for reporting any unsafe conditions, work Practices, injuries and when additional instruction is needed •Ensure proper Use of appropriate clothing, including gloves, footwear, and personal protective equipment. • Daily Safety Planner System • Tool box talk on daily basis • Required information about chemical hazards to which employees could be exposed and other hazard communication program information. • Availability of toilet, hand washing and drinking water facilities for impacted employees • Provisions for medical services and first aid including emergency procedures. • In addition, we provide specific instructions to all workers regarding hazards unique to their job assignment, to the extent that such information was not already covered in other training. 3.10 (a) SITE INDUCTION The Company will introduce an induction and training programme equipping employees with the required knowledge and awareness to refrain them from doing anything that constitutes a danger to them or others. Company Safety Manager & Senior Manager will undergo general Safety Induction training provided by the Main contractor and use that training to Implementing a system ensuring all employees assigned to Midfield Terminal Building projects will receive Site Induction & Work-related training & refreshed at six monthly intervals in their applicable language. Records will be maintained of all personnel trained, inducted and instructed in Safety. The HSE department shall induct all new employees including sub-contractors before they are allowed to start work on site to ensure that they are being familiarised with the following: - Health and safety Rules - General Site Rules

- 23. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 23 - Employees Safety Responsibilities - Familiarising with the hazards associated with their respective jobs. - Familiarising with standards and Safe Work Practises and Procedures. - Emergency and Fire evacuation procedures. An attendance register shall be kept of all persons attending induction sessions. 3.11 PROJECT SITE ORIENTATION We orientate our workers about the following subjects: The employer's Code of Safe Practices Good housekeeping, fire prevention, safe practices for operating any construction equipment Safe working procedures for cleaning, repairing, servicing and adjusting equipment and machinery Safe access to all working areas Proper use of all power tools Guarding use of fixed rotating cutting equipment Materials handling Slips, falls, and back injuries Ladder safety Ergonomic hazards, including lifting techniques and working on ladders or stooped posture for prolonged periods at one time Personal protective equipment Respiratory equipment Hazards communication Client requirements Job site physical hazards, such as heat stress, noise, and ionizing and non- ionizing radiation 3.12 EMPLOYEE COMMUNICATION SYSTEM

- 24. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 24 We recognize that open, two-way communication between management and staff on health and safety issues is essential to an injury-free, productive workforce. The following system of communication is designed to facilitate a continuous flow of safety and heath information between management and staff in a form that is readily understandable and consists of the following items:- Site Specific Safety Plan (SSSP) Workplace safety and health training programs Regular required weekly safety meetings . Effective communication of safety and health concerns between workers and supervisors Posted or distributed safety information. New worker orientation, required for all new employees. 3.13 RECORD KEEPING We have taken the following steps to implement and maintain the following records to document our SSSP Program:- Records of hazard assessment inspections, including the person(s) or persons conducting the inspection, the unsafe conditions and work practices that have been identified and the action taken to correct the identified unsafe conditions an work practices, are recorded on a hazard assessment and correction form; Documentation of safety an health training for each worker, including the worker's name or other identifier, training dates, type(s) of training, and training providers are recorded in a worker training and instruction from. Inspection records and training documentation will be maintained according the following checked schedule:- For three years, except for training records of employees who have worked For less than one year which are provided to the worker upon termination of employment Other records are required by contract specifications and/or local regulations. 3.14 ACCIDENT/EXPOSURE INVESTIGATIONS Procedures for investigating workplaceaccidents and hazardous substances exposures include:- Responding to the accident scene as soon as possible

- 25. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 25 Reporting to Project Manager Reporting immediately to the appropriate Client point-of-contact Interviewing injured workers and witnesses Examining the workers for factors associated with the accident exposure. Determining the cause of the accident/exposure Taking corrective action to prevent the accident/exposure from reoccurring and Recording the findings and corrective actions taken. 3.15. EMERGENCY ACTION PLAN In the event an evacuation of the work site if necessary, it will be announced and all staff and visitors are to leave the area immediately and assemble at a the pre-determined emergency meeting location mentionedin Obayashi Evacuation route plan. The Supervisor (oracting supervisor) shall contactProject Manager, any timean emergency action plan has been enacted. The on-site Client Representative will also be contacted immediately to Obayashi. a. FIRST AID First aid facilities will be kept on site for minor injuries as well as for the purpose of preserving life and minimising the consequences of injury and illness until help from a medical practitioner or nurse can be obtained. First Aid Box Portable First Aid Kit. Display signboard with list of first aiders names and mobile numbers The Safety Manager/First Aider will be responsible for re-stocking the first aid box All injurieshowever minorwill beentered in the site accidentbook.Reportableaccidents and Dangerous Occurrences must be recorded on with a copy being sent to the company’s Health and Safety Manager. 3.16. SITE SPECIFIC MEDICAL EMERGENCY PLAN In the event serious injury or illness occurs to a employee, he/she is to be taken immediately to: the nearest Emergency Medical Center. For minor injuries such as simple cuts, sprains, etc. The employee will be taken to: nearest required medical treatment facility. If in doubt, assume the worst and transport the employee to: henearest EmergencyMedical Center. The on-site Client Representative shall be notified as soon as possible. In cases of serious injury or illness, the employee is to be sent immediately to the nearest hospital, by ambulance if necessary.

- 26. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 26 If the injury is the result of an accident on site then an Accident Report to be filled out and submitted to the on-site Client representative. Employees MUST report all injuries or illnesses, as soon as possible, to the on-site supervisor. 3.17. HAZARD COMMUNICATION PLAN In order to comply with OSHA 1910.1200, Hazard Communications Standard, and the following written Hazard Communication Program has been established. a. Containerlabeling A qualified employee shall verify that all in-coming containers received for use are clearly labeledto include: Content identification. (The identity of the contents must match corresponding ( MSDS.) Appropriate hazard warnings, (including routes of entry and target organs.) Name and St. address of the manufacture. The supervisor of each area will ensure that all secondary containers (those containers other than the original) will be labeled with: Content identification. (The identity must match the corresponding MSDS.) Appropriate hazard warnings, (including route of entry and target organs) Name and St. address of the manufacture. The supervisor of each area will ensure that all secondary containers (those containers other than the original) will be labeled with: Content identification. (The identity must match the corresponding MSDS.) Appropriate hazard warnings, (including route of entry and target organs) b. Material Safety Data Sheets (MSDS) A qualifiedemployeewill beresponsiblefor obtainingandmaintaining material safetydata sheets for the company. It is Industries, policy that when toxic or hazardous substances are received without an MSDS or the appropriate MSDS is not on file at Industries, that the chemical will not be accepted until such information is available. A qualified employee will reviewincoming date sheets for new and significant health/safety information. They will see that any new information is passed on to the affected employees.

- 27. ARKI GROUP DESIGN LLC Document No. AGD/HSE/SSSP/01 Date ofIssue: 14/06/2020 27 If a MSDS is incomplete, they will request a new MSDS from the manufacturer/supplier. MSDS sheets are available to each employeeduring his/her work shift. 3.18. WASTE MANAGEMENT Material waste – there will be a team of workers involved in continuously cleaning the work area, clearing all the debris, rubbish etc, & removing the same to the skips provided at the designated area. Food waste – there will be a team of workers involved in cleaning the break out area removing of all the food waste. Trash bins are provided with heavy duty polythene bags which will be removed and disposed off to the skips in regular intervals.