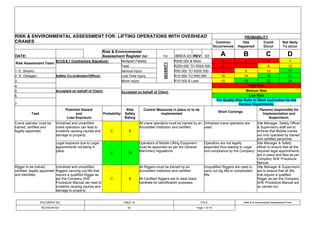

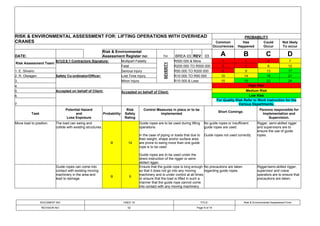

This document provides a risk assessment for lifting operations using overhead cranes. It identifies several potential hazards including using uncertified or untrained crane operators, riggers, and lifting equipment. Control measures are outlined such as ensuring all operators and riggers are properly trained and certified, performing pre-use checks of cranes, not exceeding crane weight limits, and barricading lifting areas. Responsible parties for implementing controls and supervising work are also specified. The assessment was performed to reduce risks of injuries or property damage during crane lifting operations.