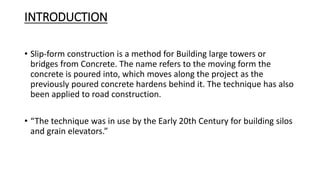

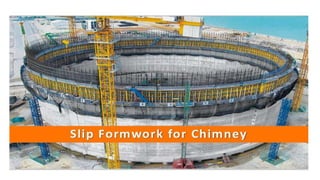

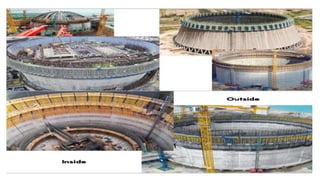

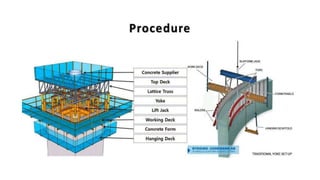

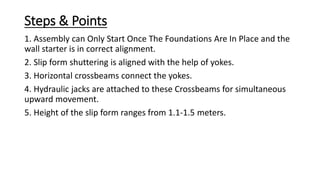

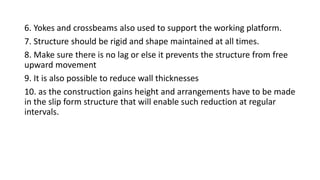

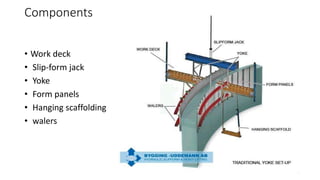

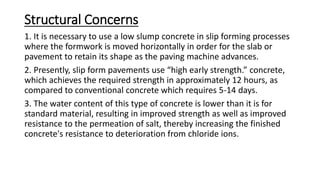

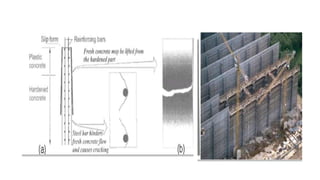

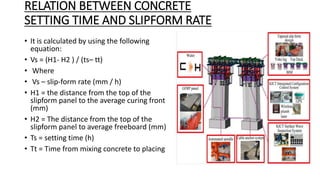

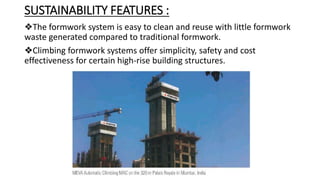

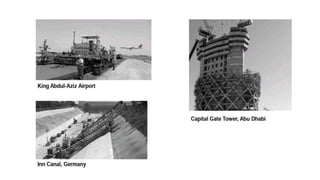

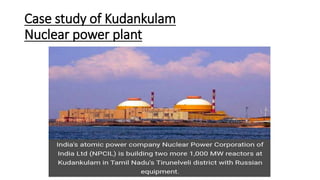

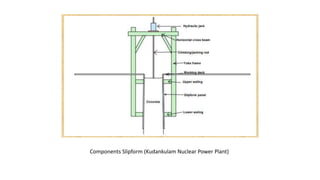

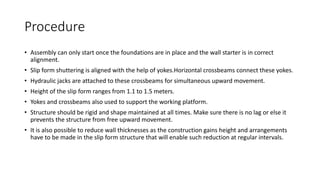

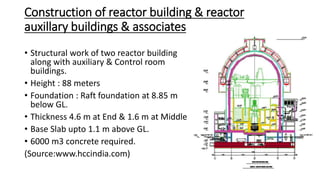

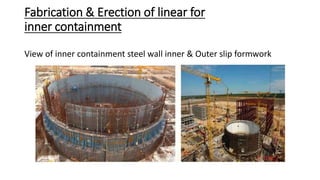

This document provides information about slip formwork construction for chimneys. It begins with an introduction to slip formwork and its use for building tall structures like silos and grain elevators in the early 20th century. It then discusses the process of slip forming involving a moving form that is jacked upwards as concrete is poured in. The document outlines the key steps, components, structural concerns and provides an example case study of slip forming used at the Kudankulam Nuclear Power Plant in India.