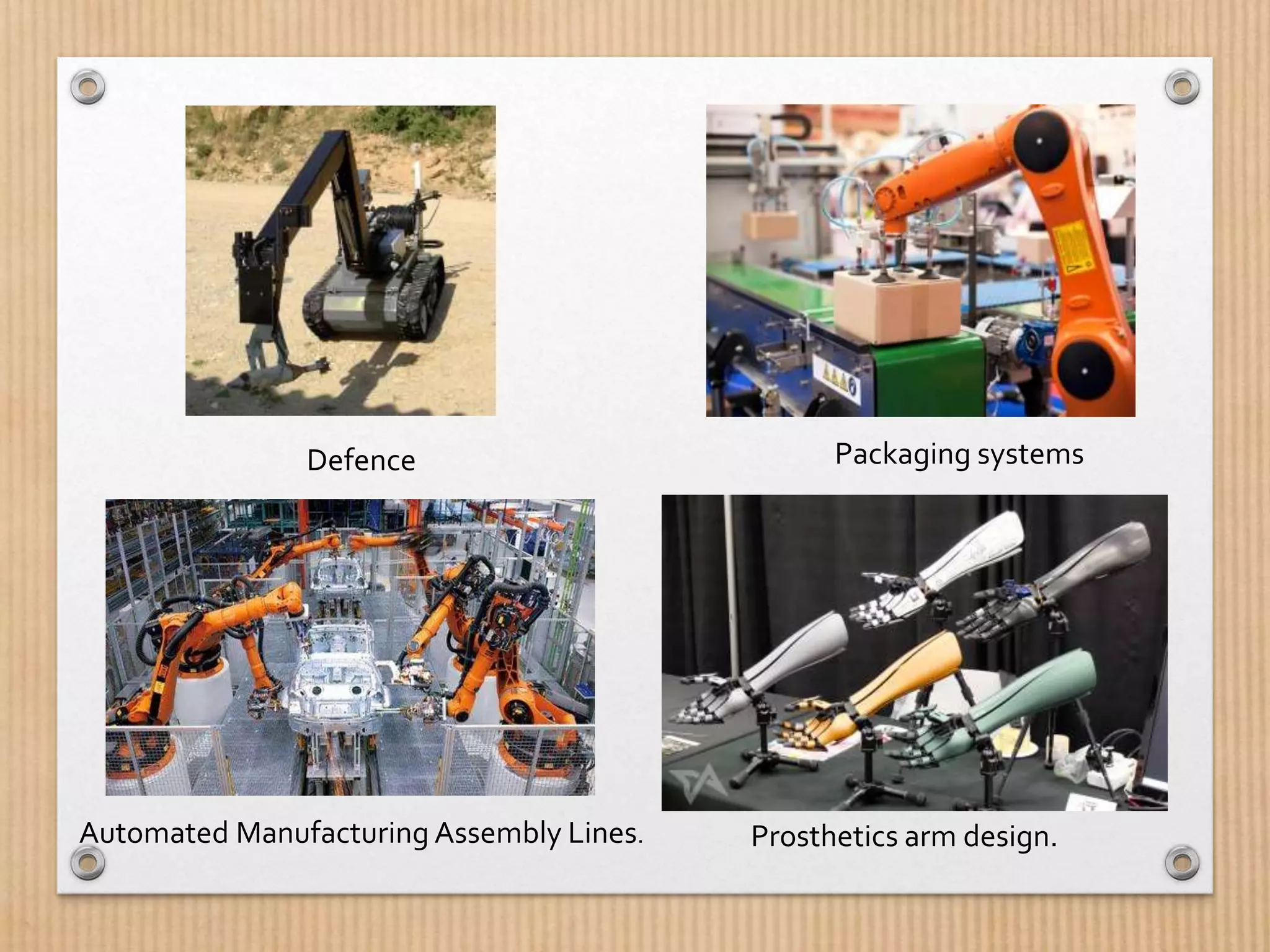

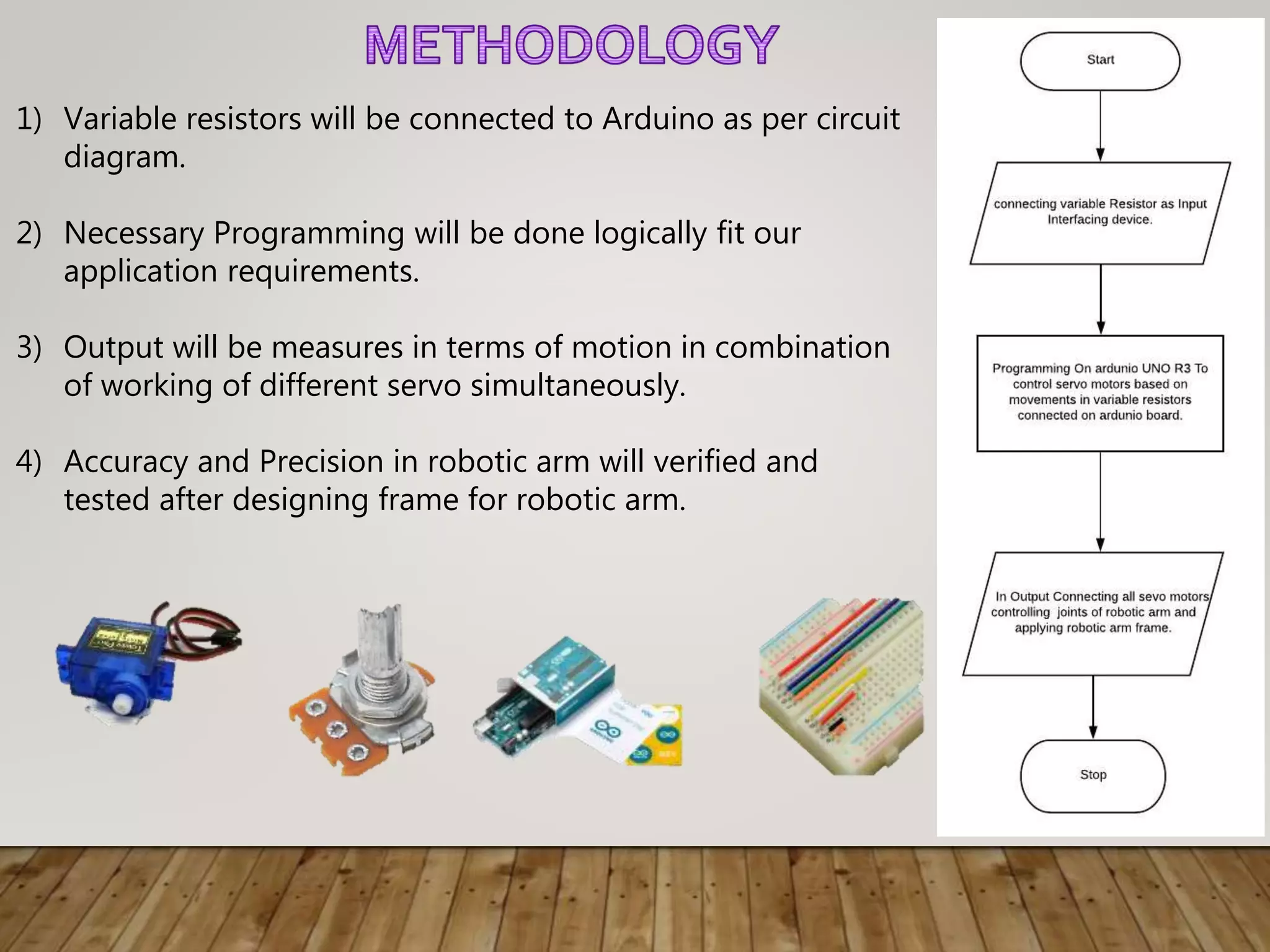

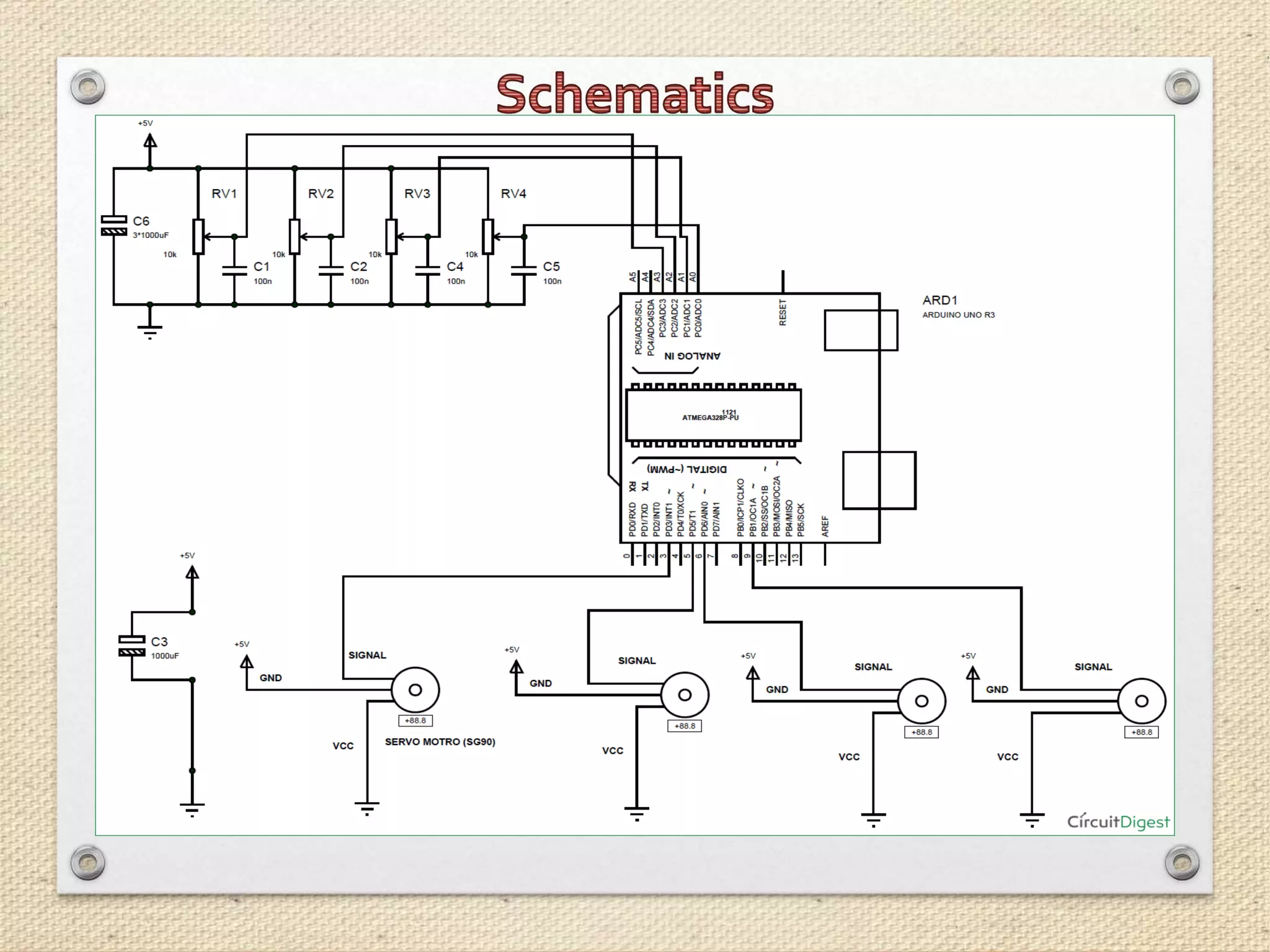

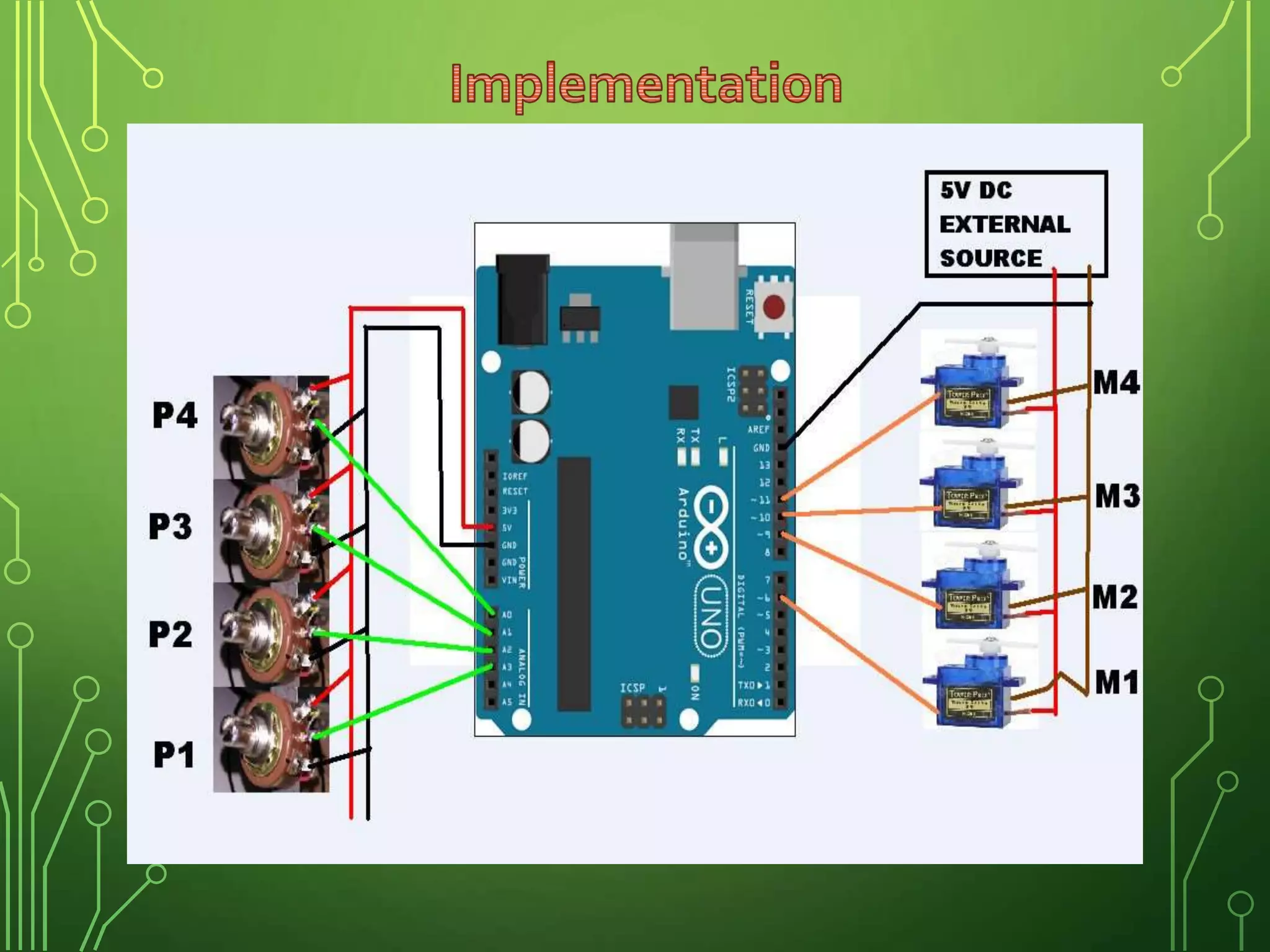

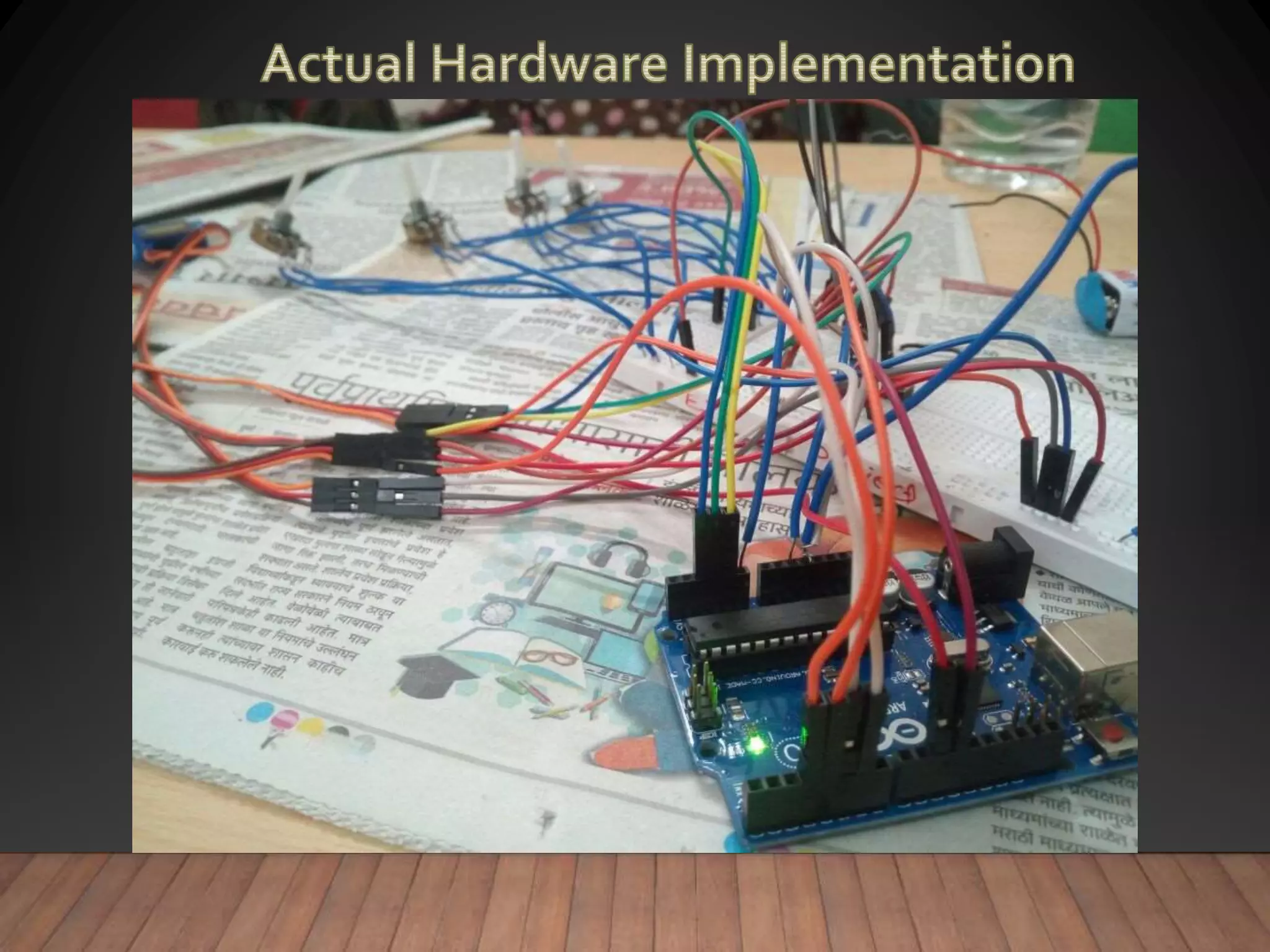

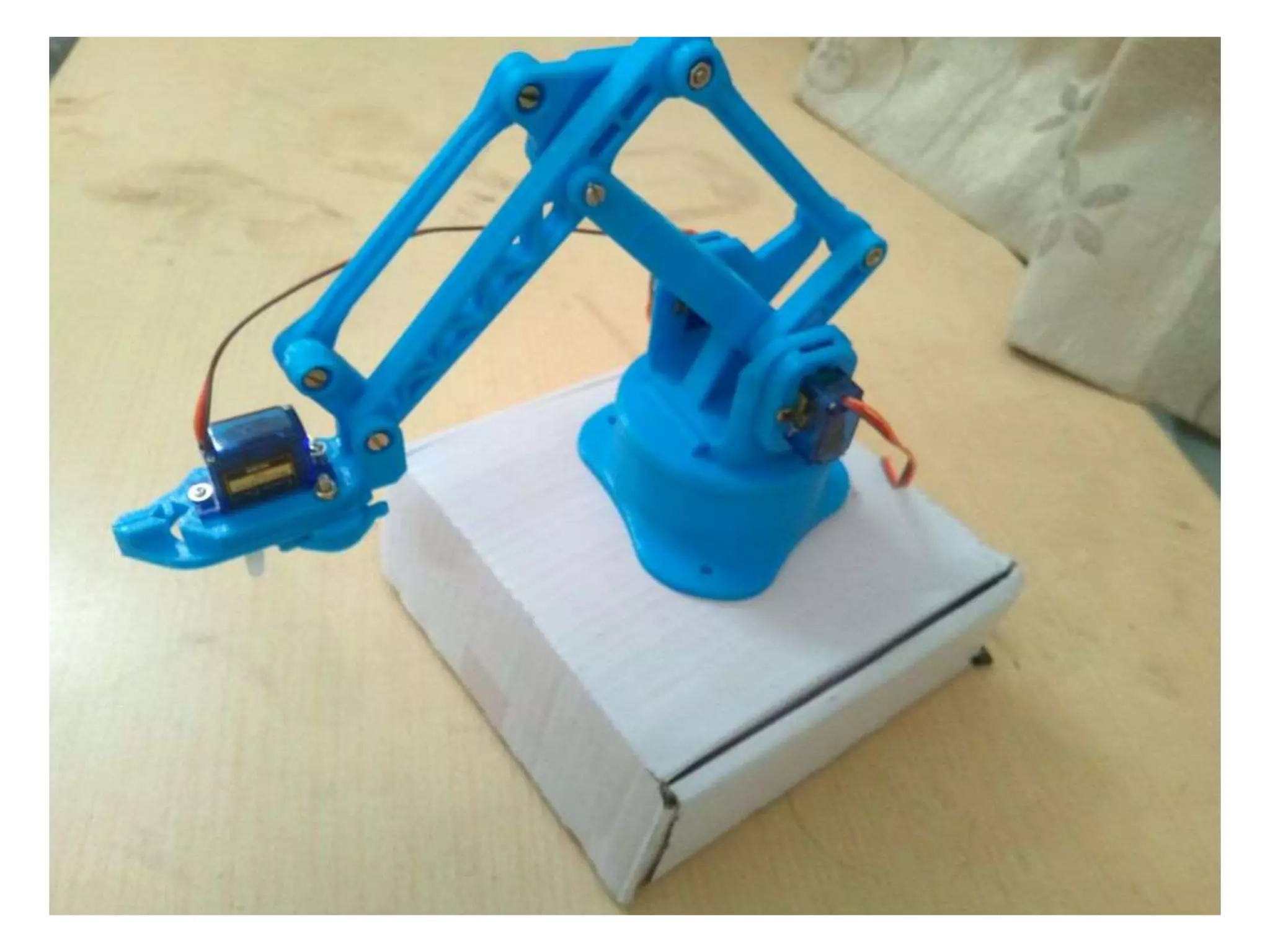

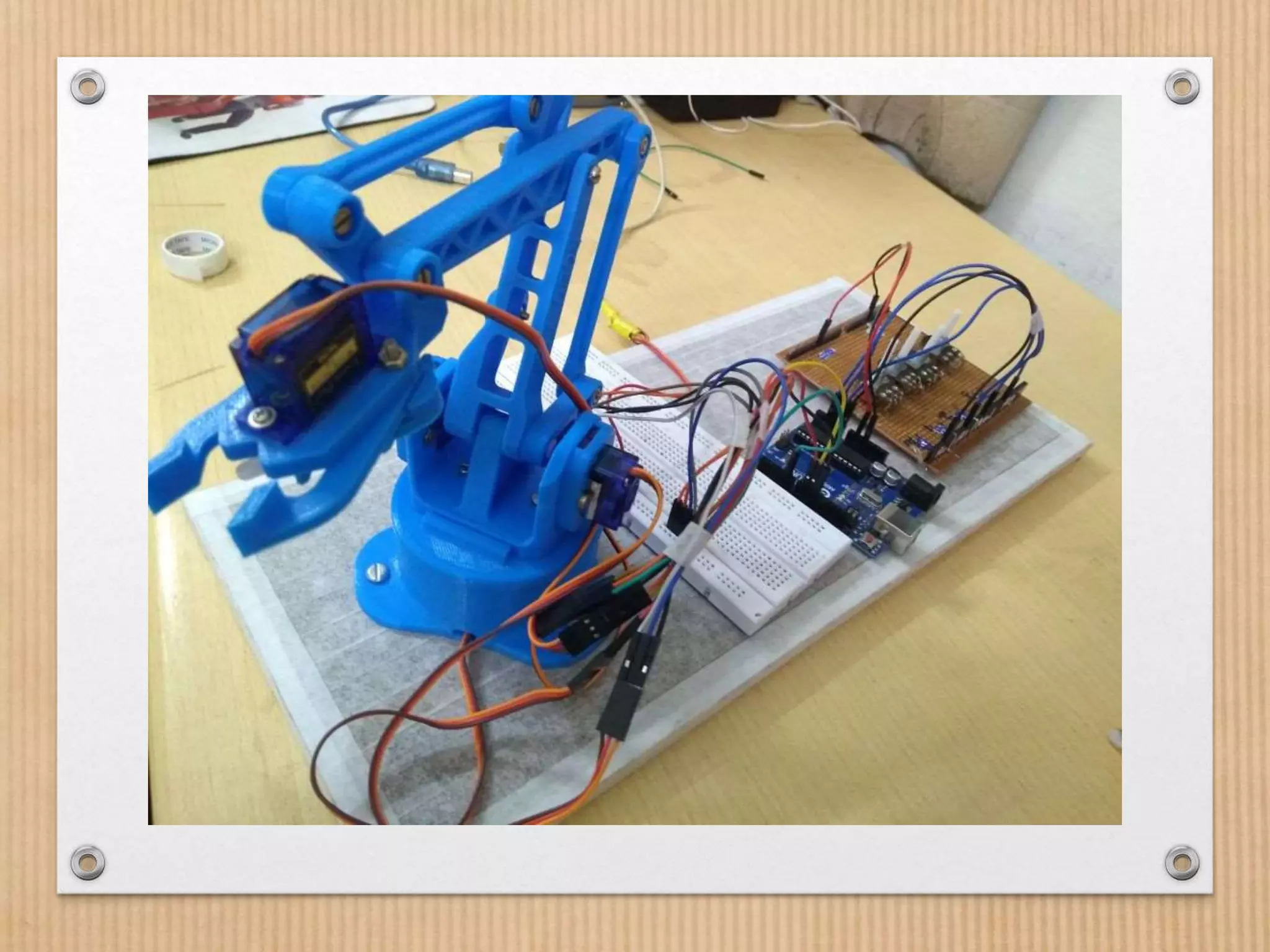

This document describes designing and developing a robotic arm using servo motors controlled by an Arduino Uno microcontroller. The robotic arm uses 4 servo motors to control each joint and imitate the motion of a human arm. The arm is physically controlled, with the signals replicated by the microcontroller to synchronously control the servo motors of the robotic arm. The objectives are to help disabled people perform tasks independently and to use such robotic arms for applications like automated manufacturing and bomb disposal.

![[1] https://create.arduino.cc/projecthub/ChanR19/simple-programmable-robotic-

arm-bd28a0

[2] https://www.electronicshub.org/robotic-arm/

[3] https://maker.pro/projects/arduino/hand-gesture-controlled-robotic-arm-arduino

[4] https://create.arduino.cc/projecthub/benbobgray/mearm-robot-arm-your-robot-

v1-0-326702?ref=search&ref_id=robot%20arm&offset=2

[5] https://create.arduino.cc/projecthub/ammaratef45/control-robot-arm-with-your-

android-phone-adbfb3?ref=search&ref_id=robot%20arm&offset=3

[6] https://create.arduino.cc/projecthub/team-3/robot-arm-arduino-101-team-3-

631b48?ref=search&ref_id=robot%20arm&offset=0](https://image.slidesharecdn.com/minorprojectppt-180604145551-191207130647/75/robotic-arm-3d-printed-with-microcontroller-21-2048.jpg)