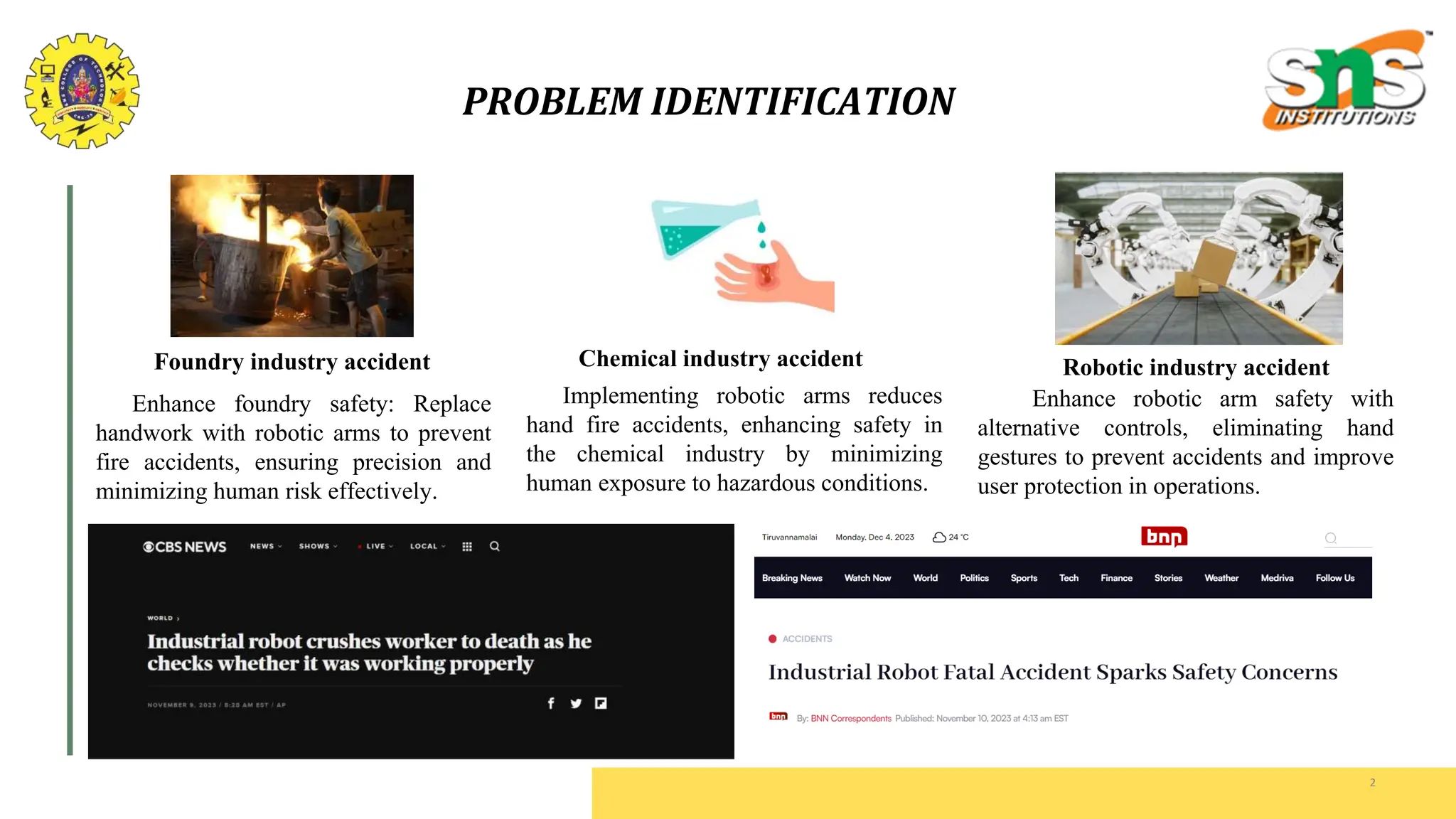

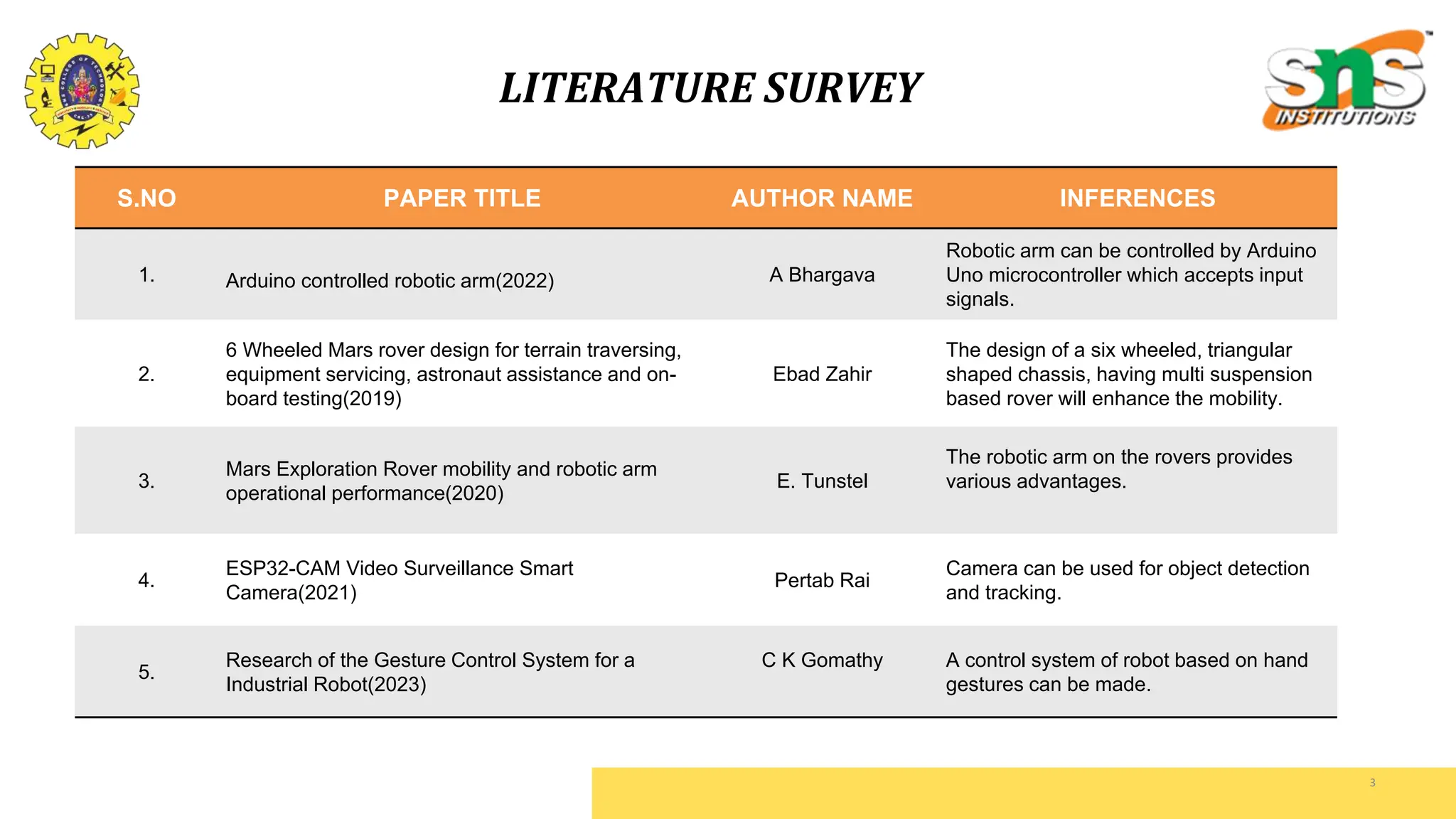

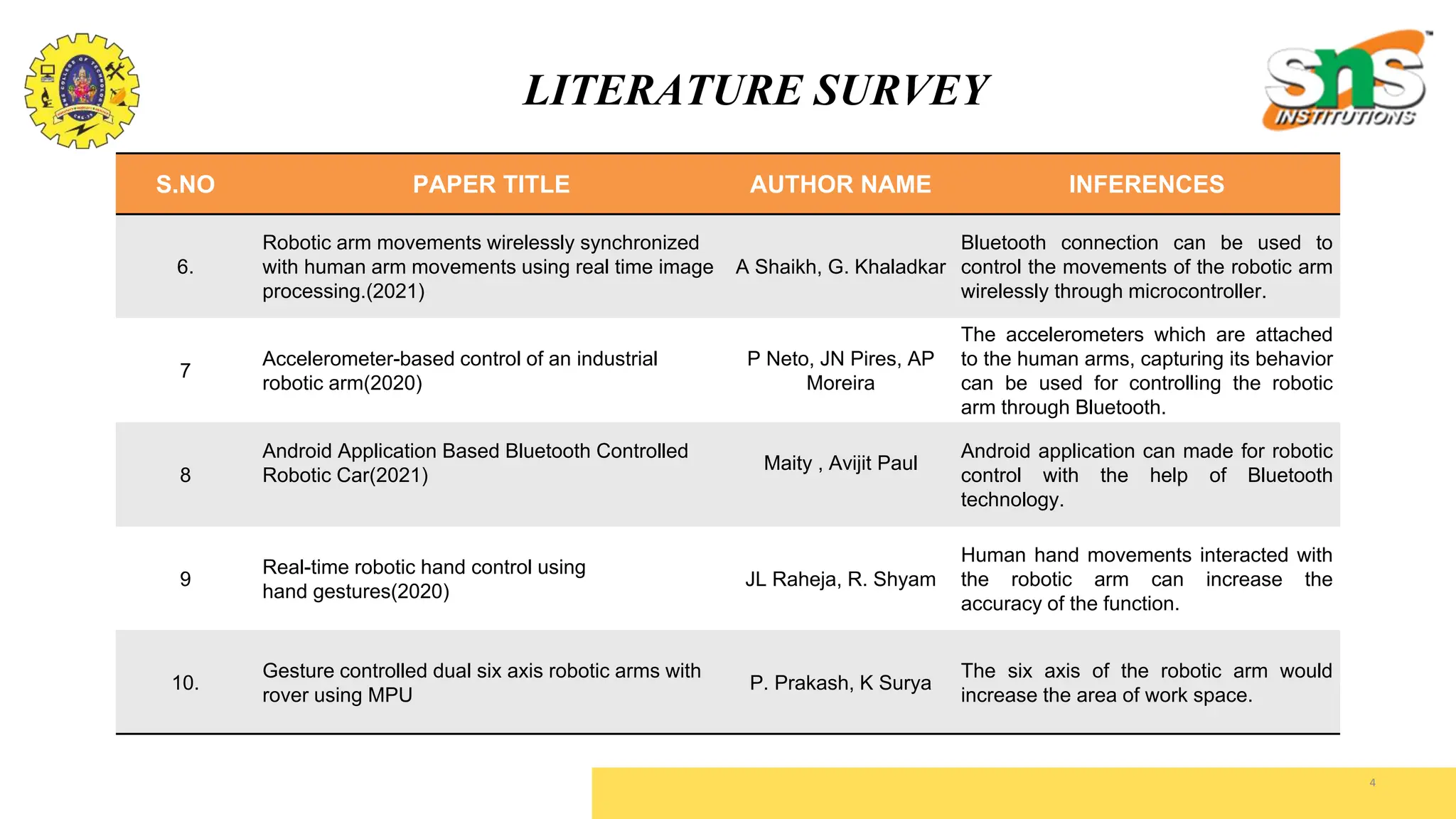

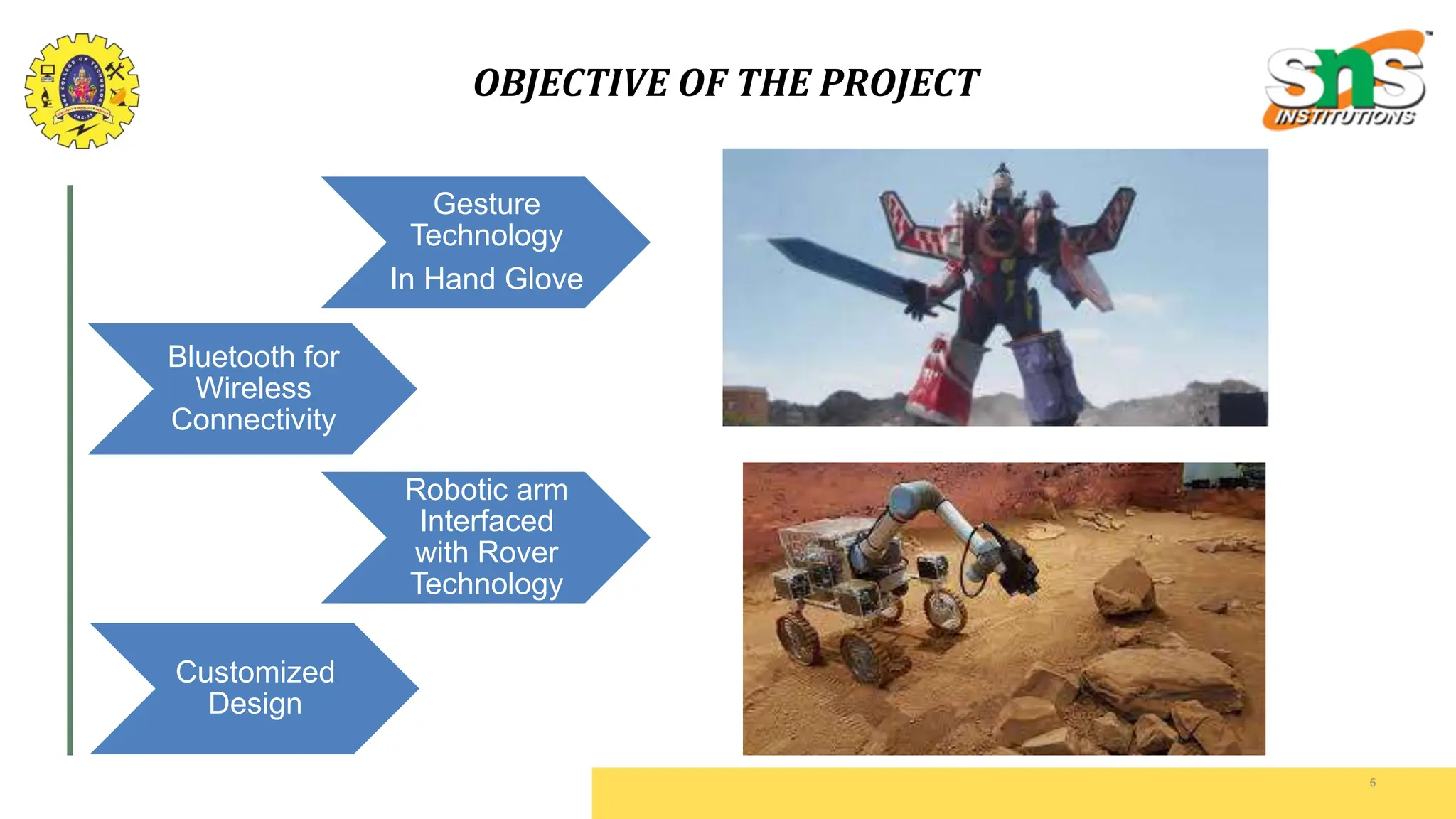

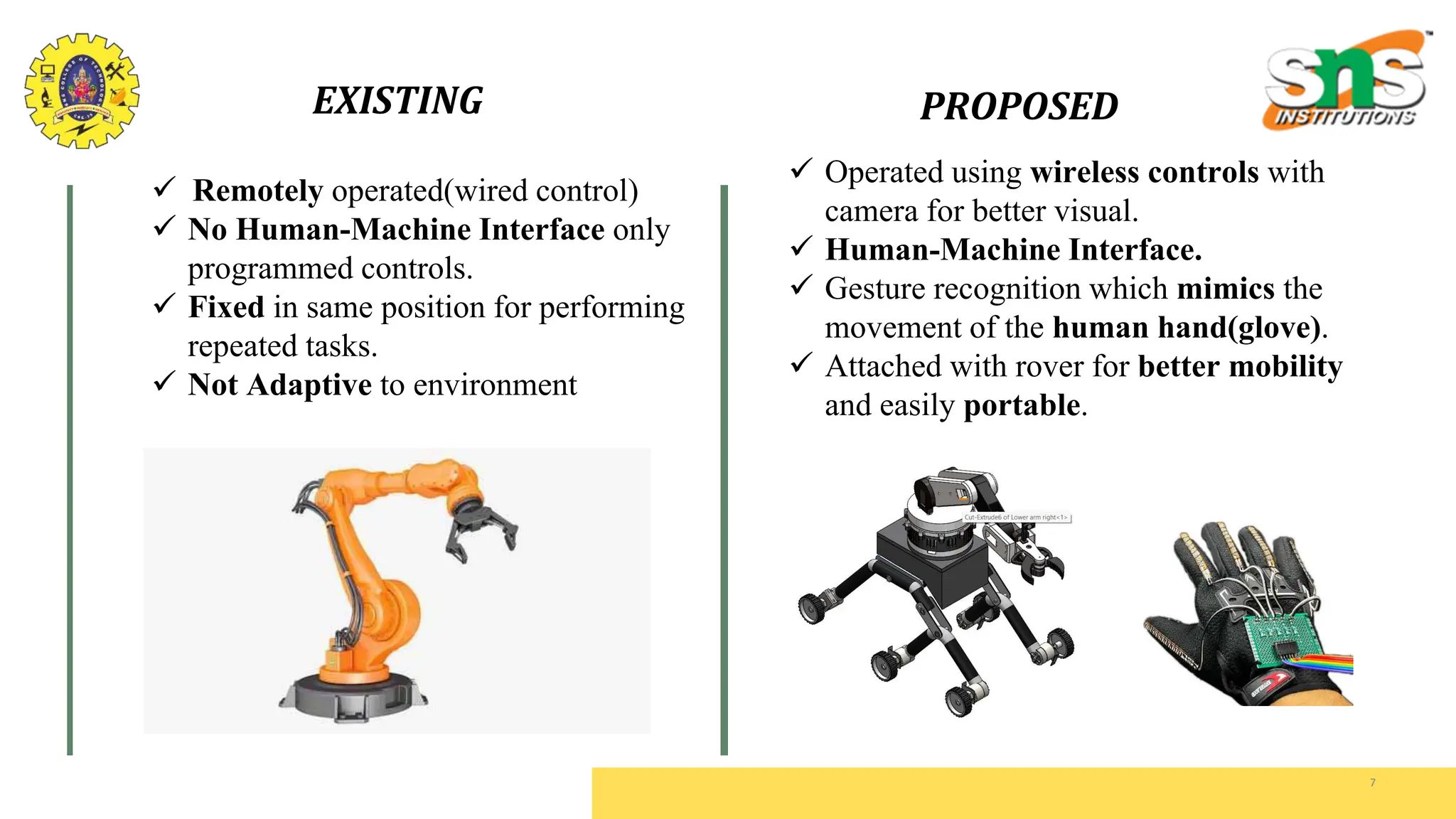

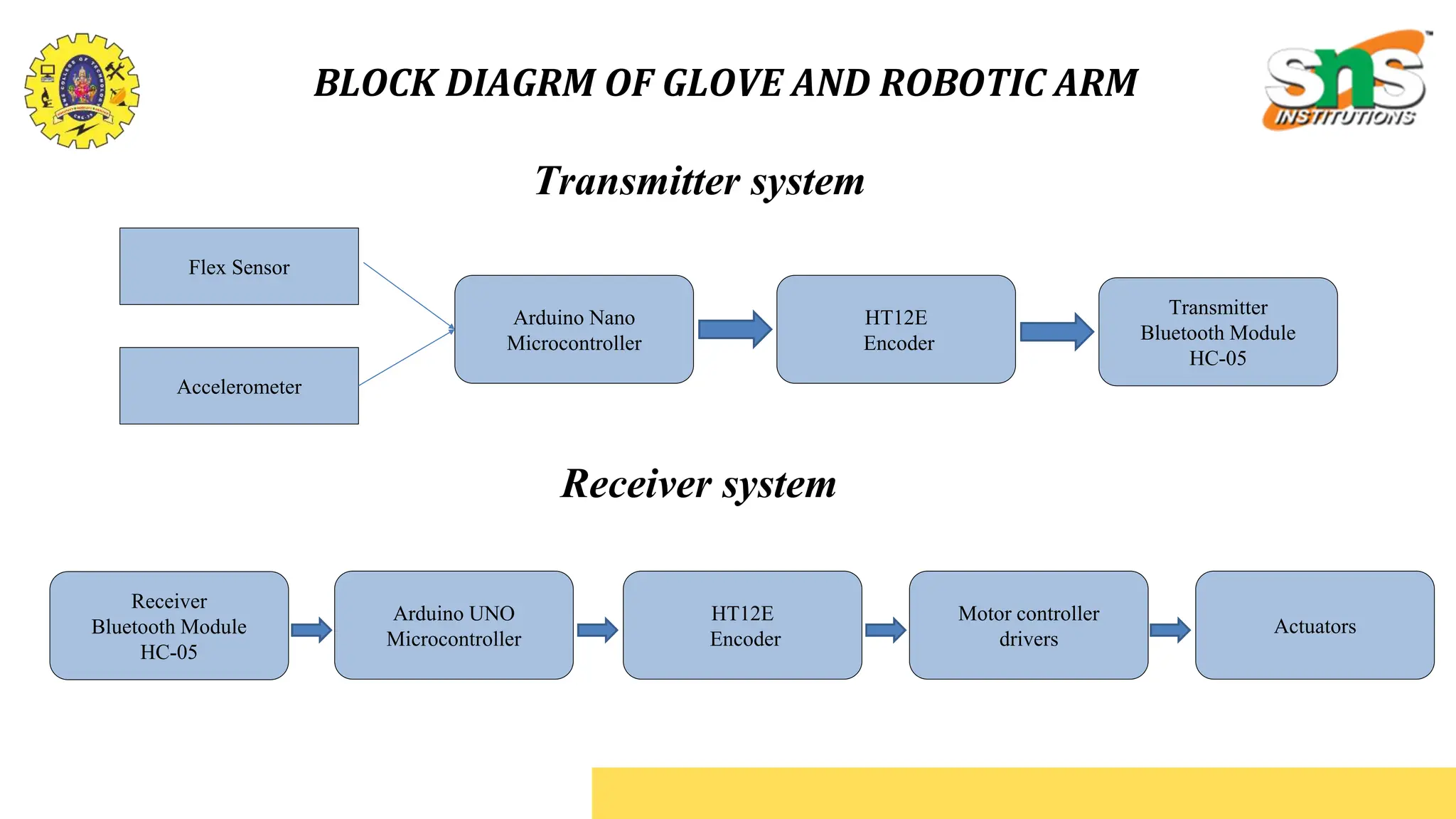

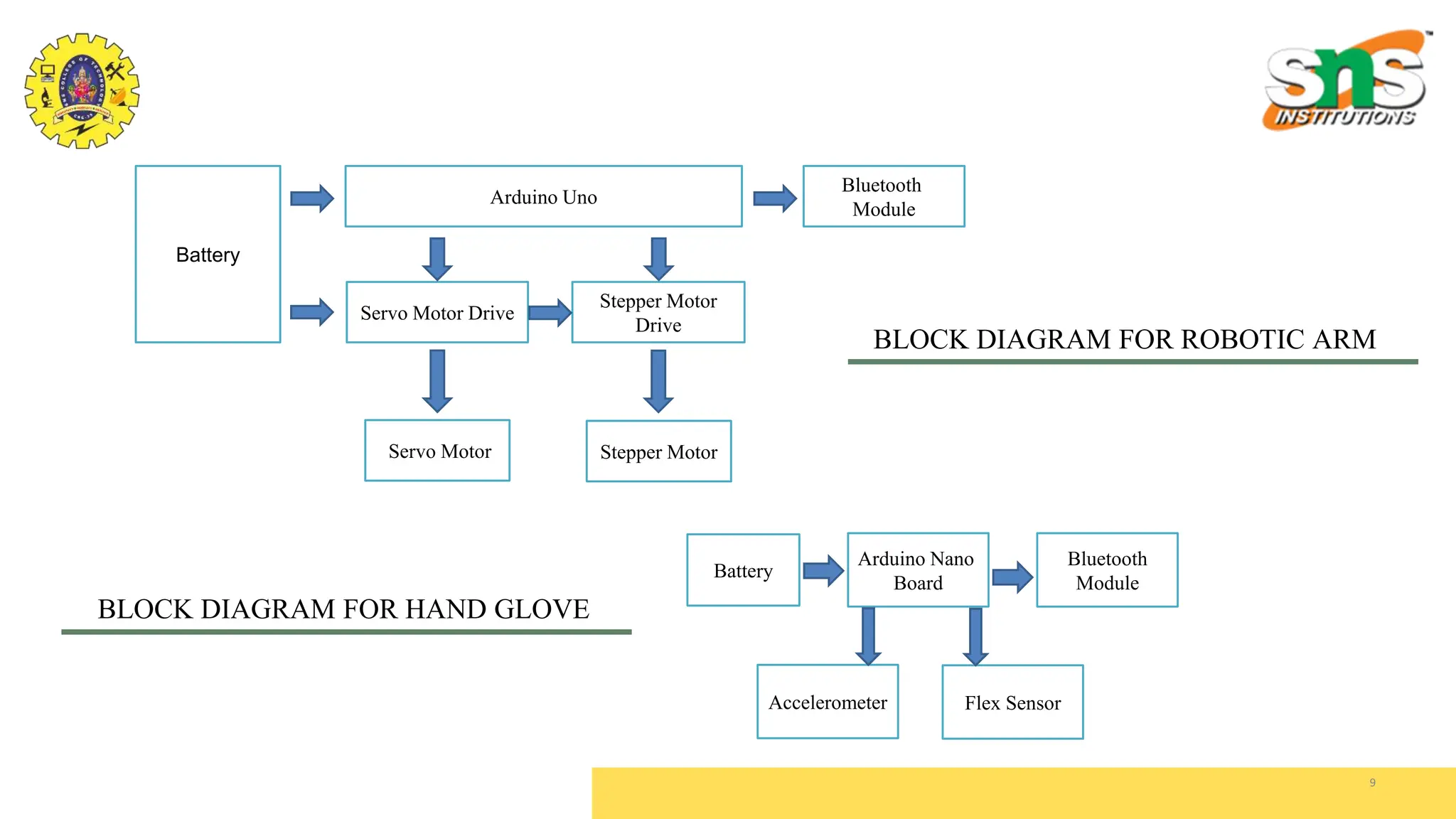

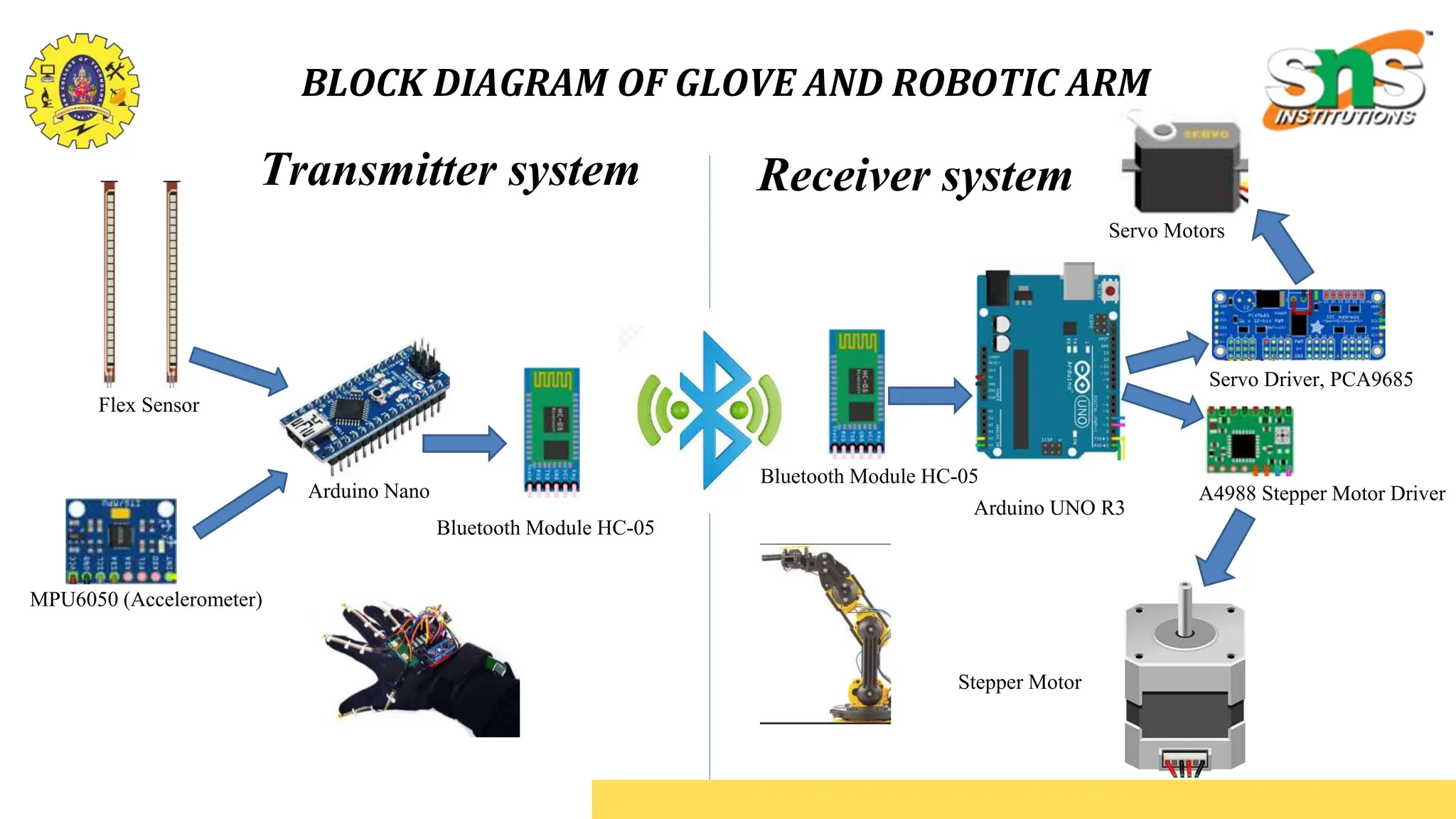

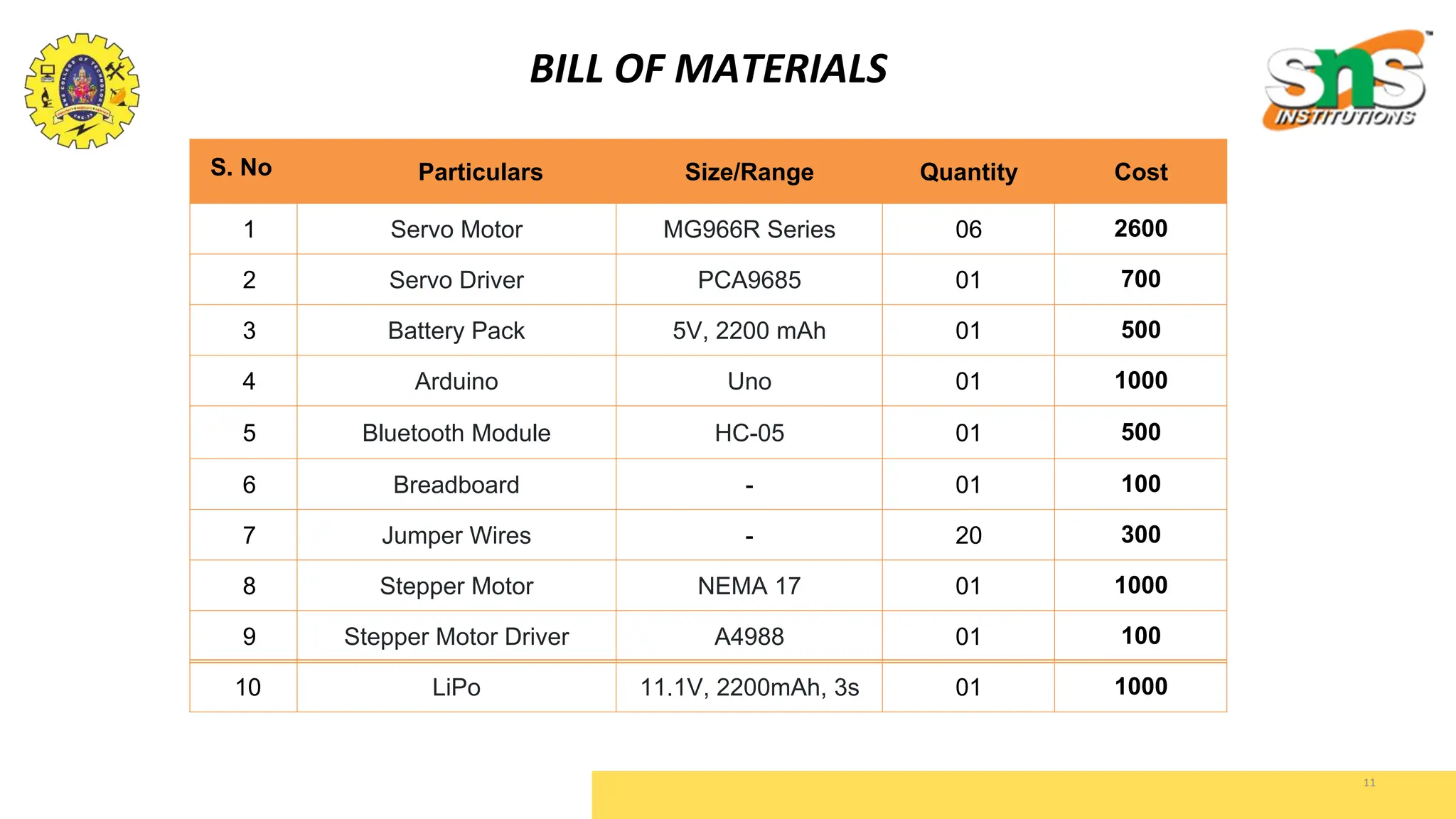

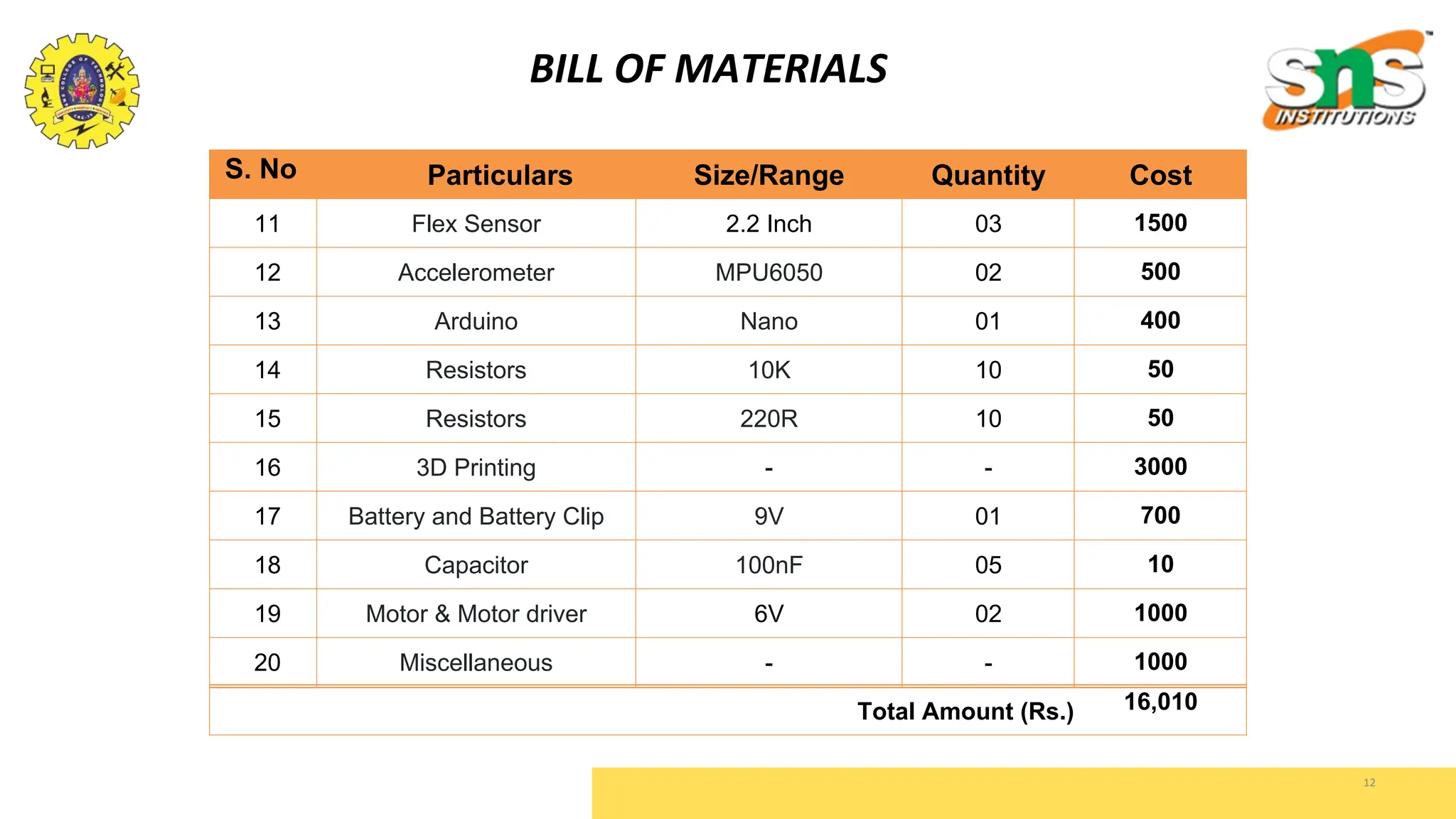

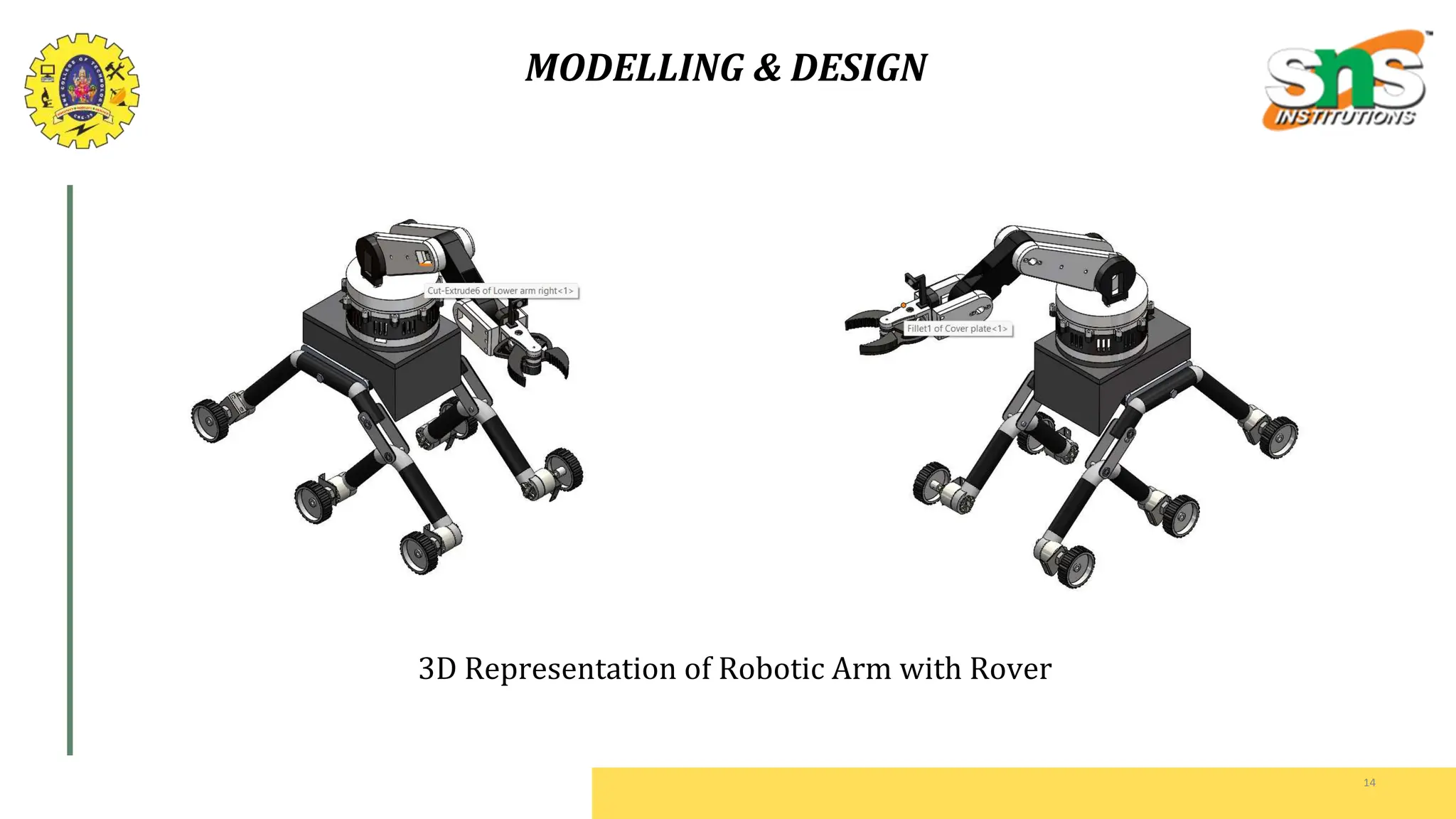

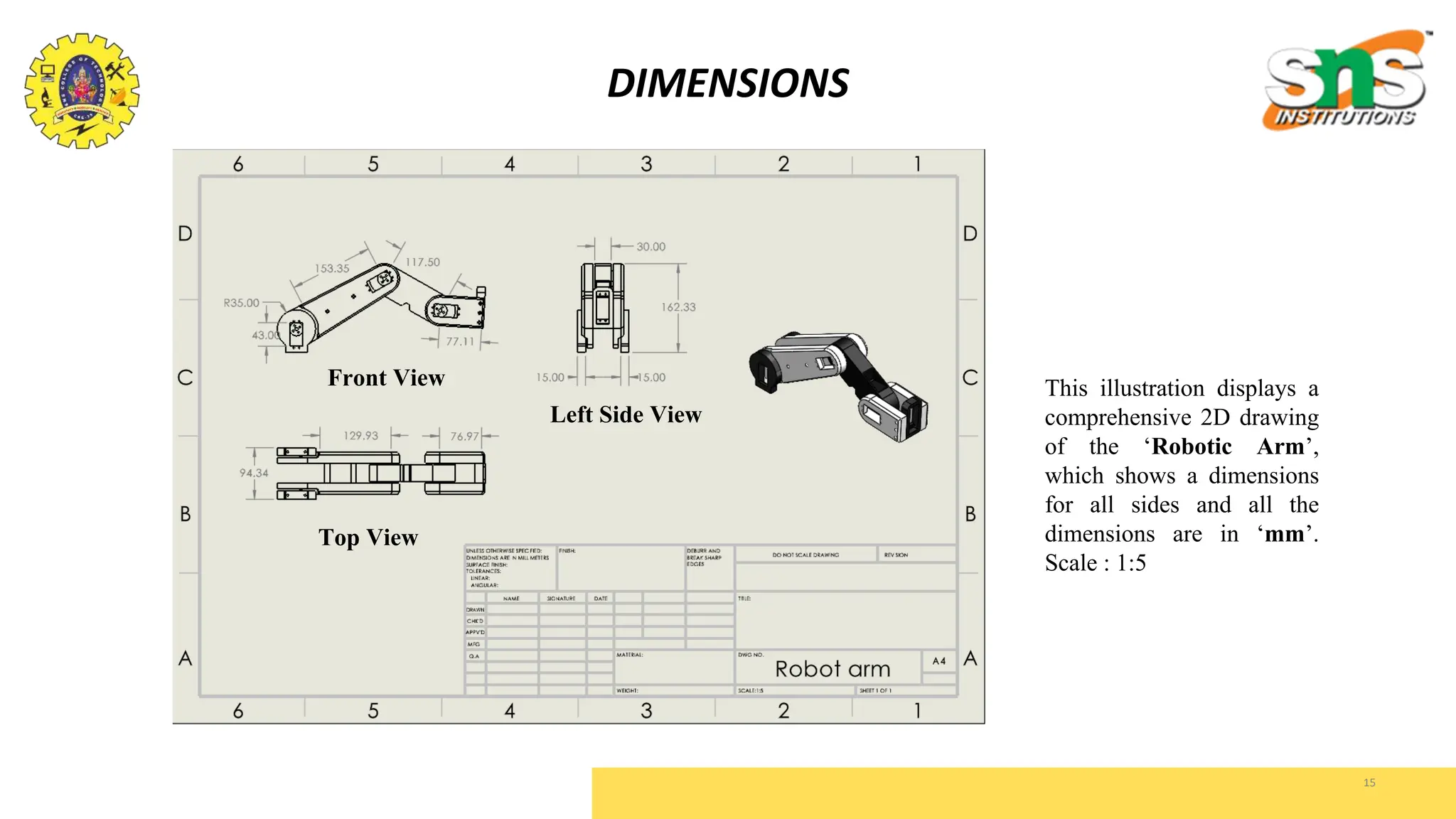

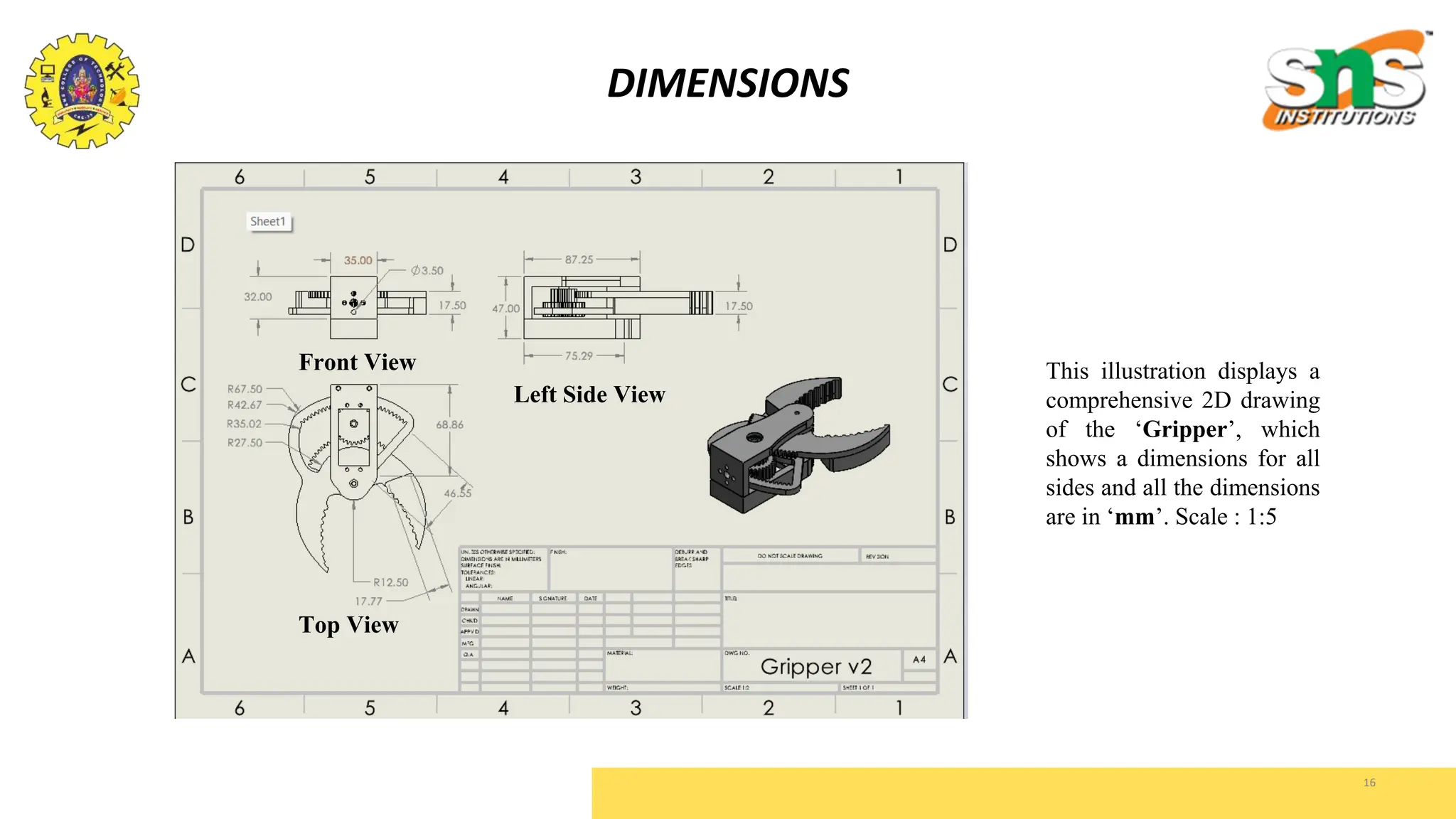

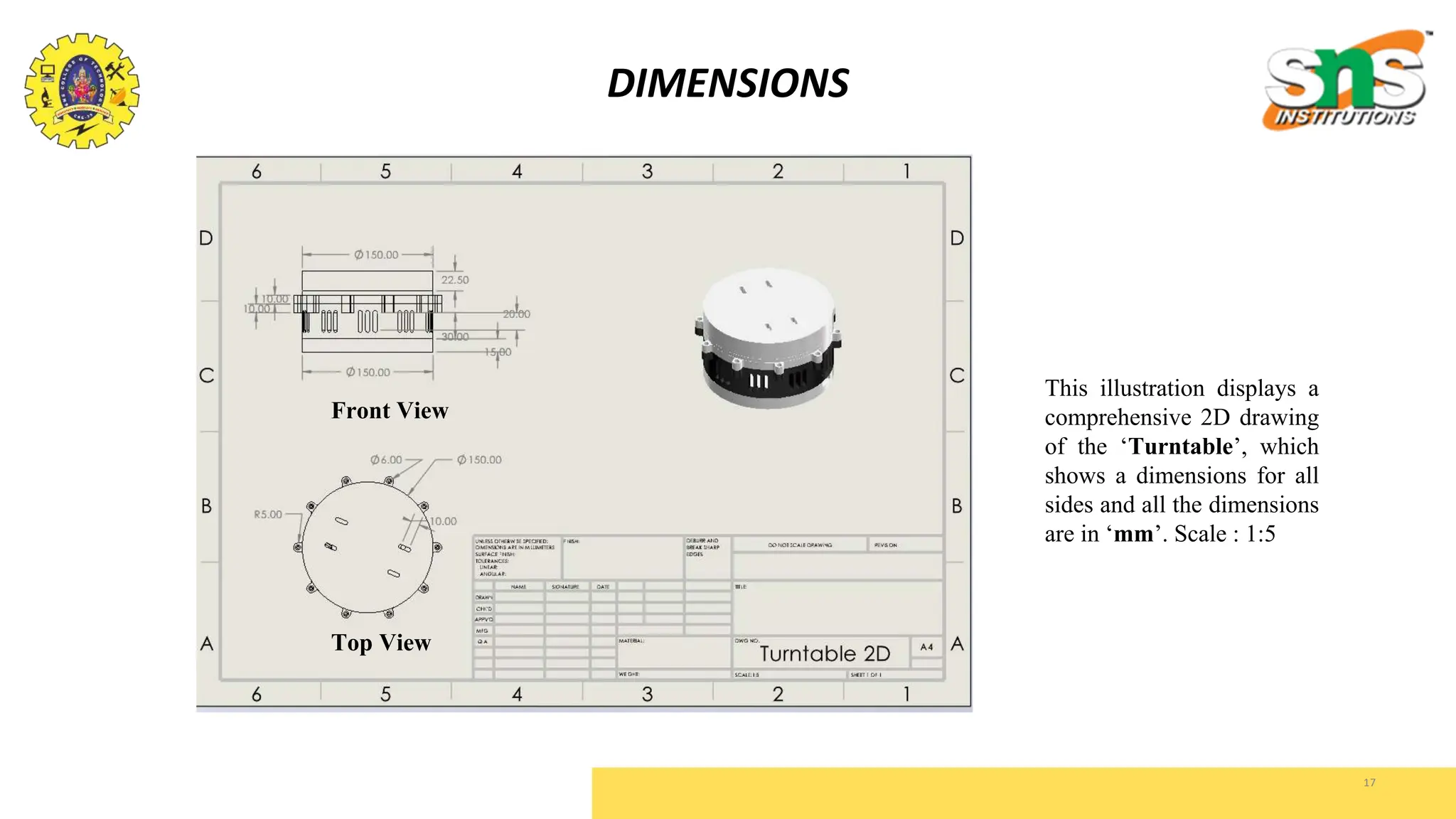

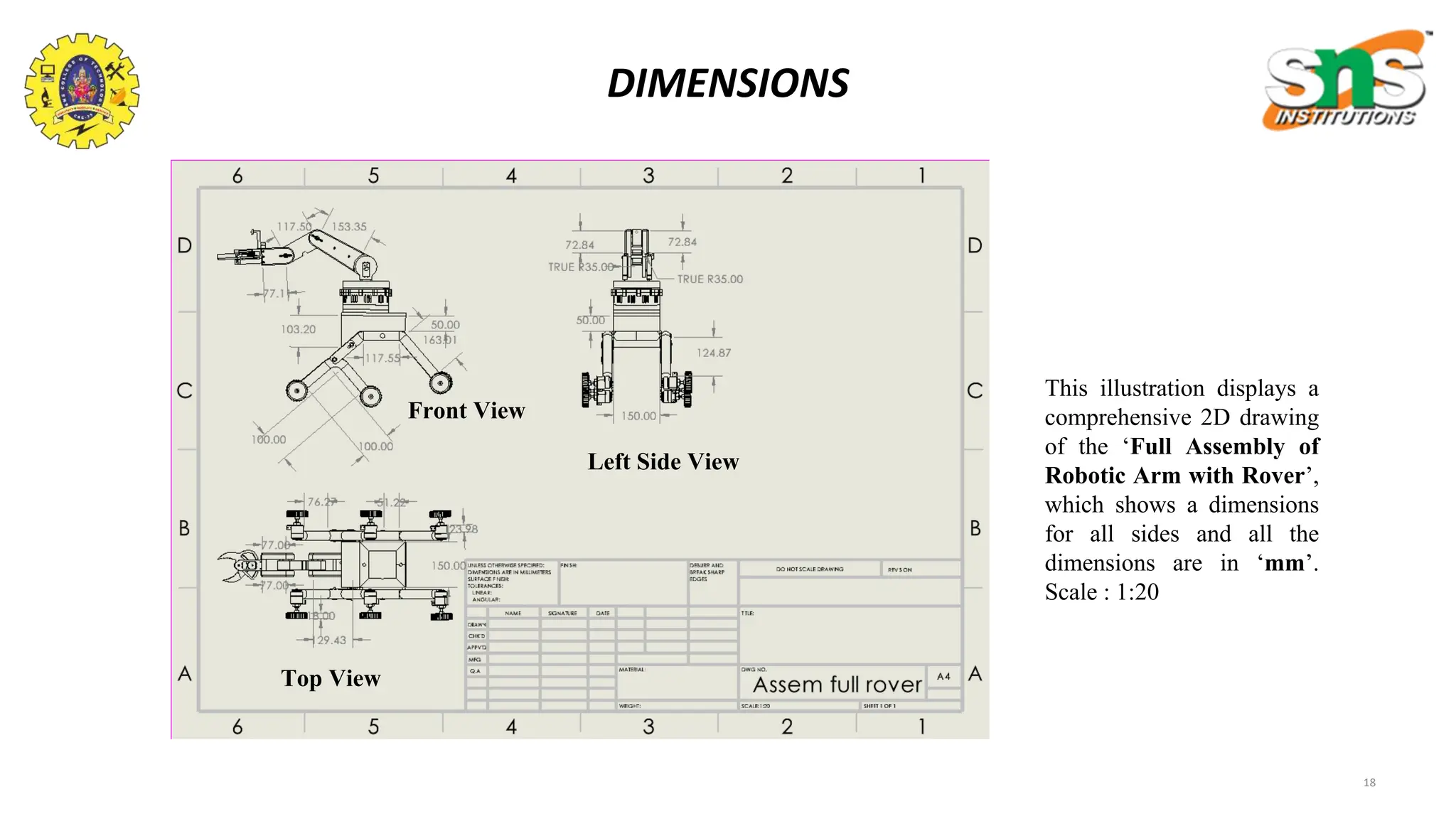

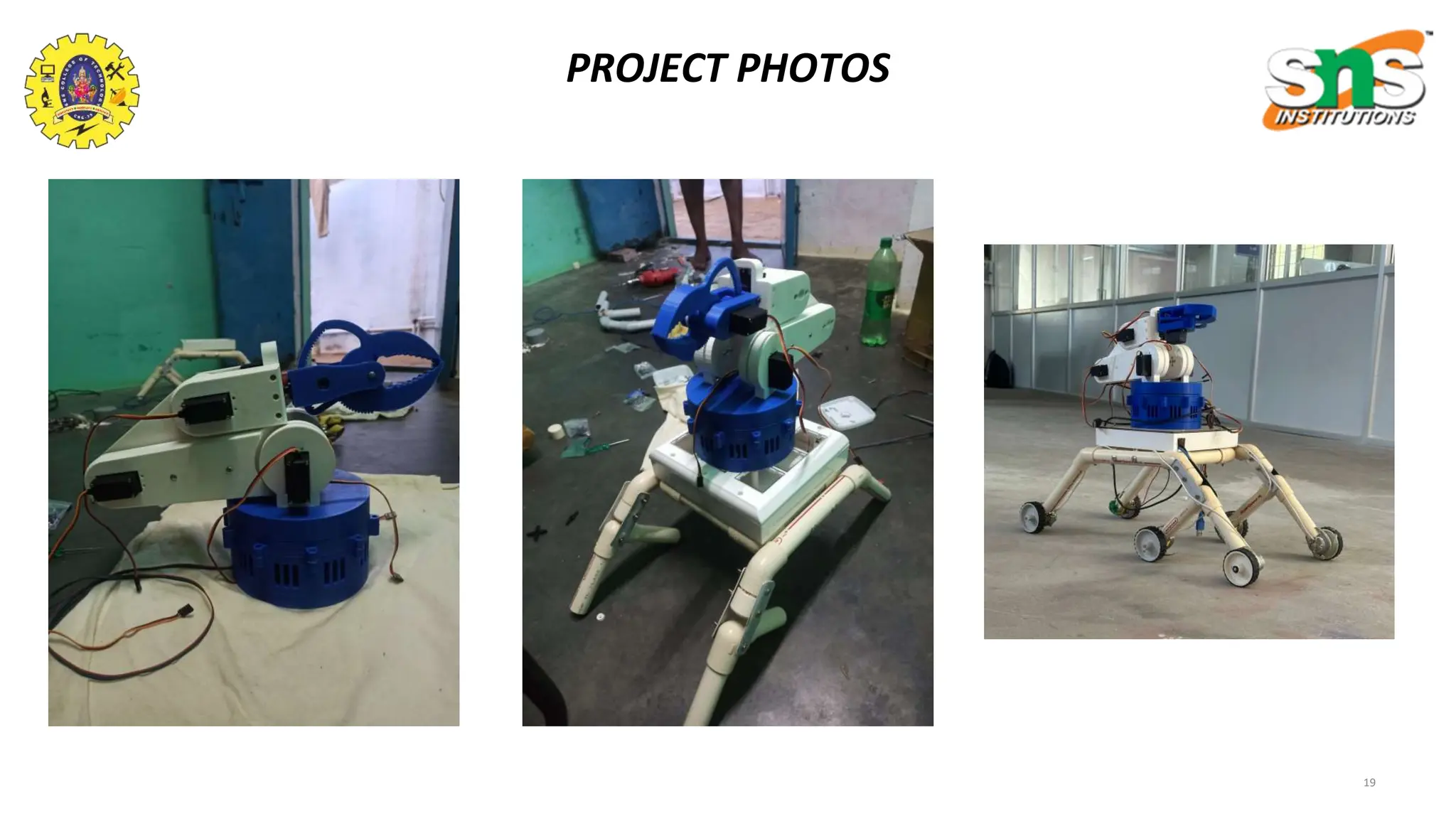

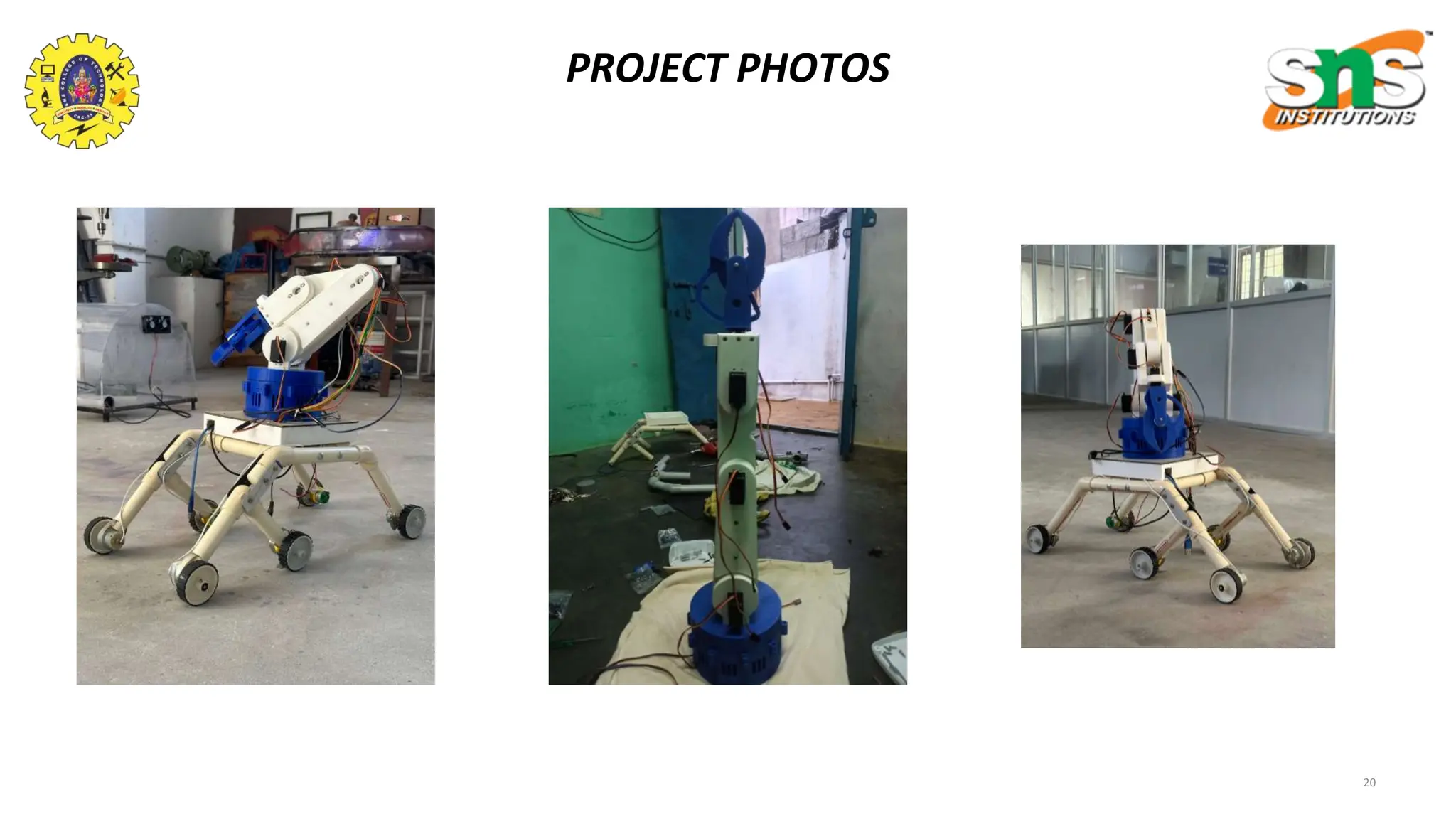

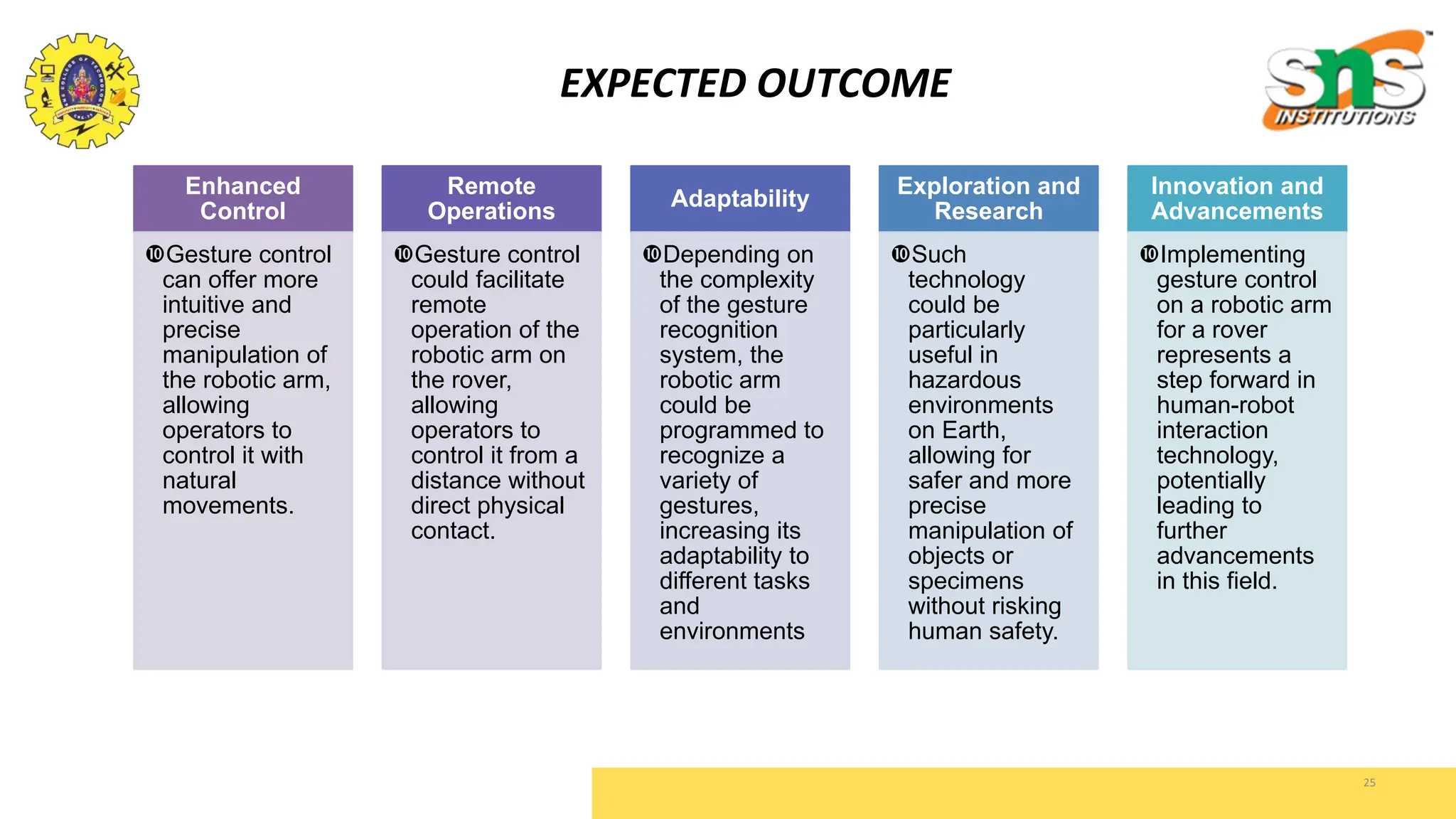

The document details a project focused on developing a gesture-enabled robotic arm on a rover aimed at enhancing safety in industries by minimizing human risk during operations. It includes a literature review, project objectives, proposed designs, and a bill of materials that outlines the required components for implementation. The project aims to facilitate intuitive control through gesture recognition, allowing for adaptive and remote operation in hazardous environments.