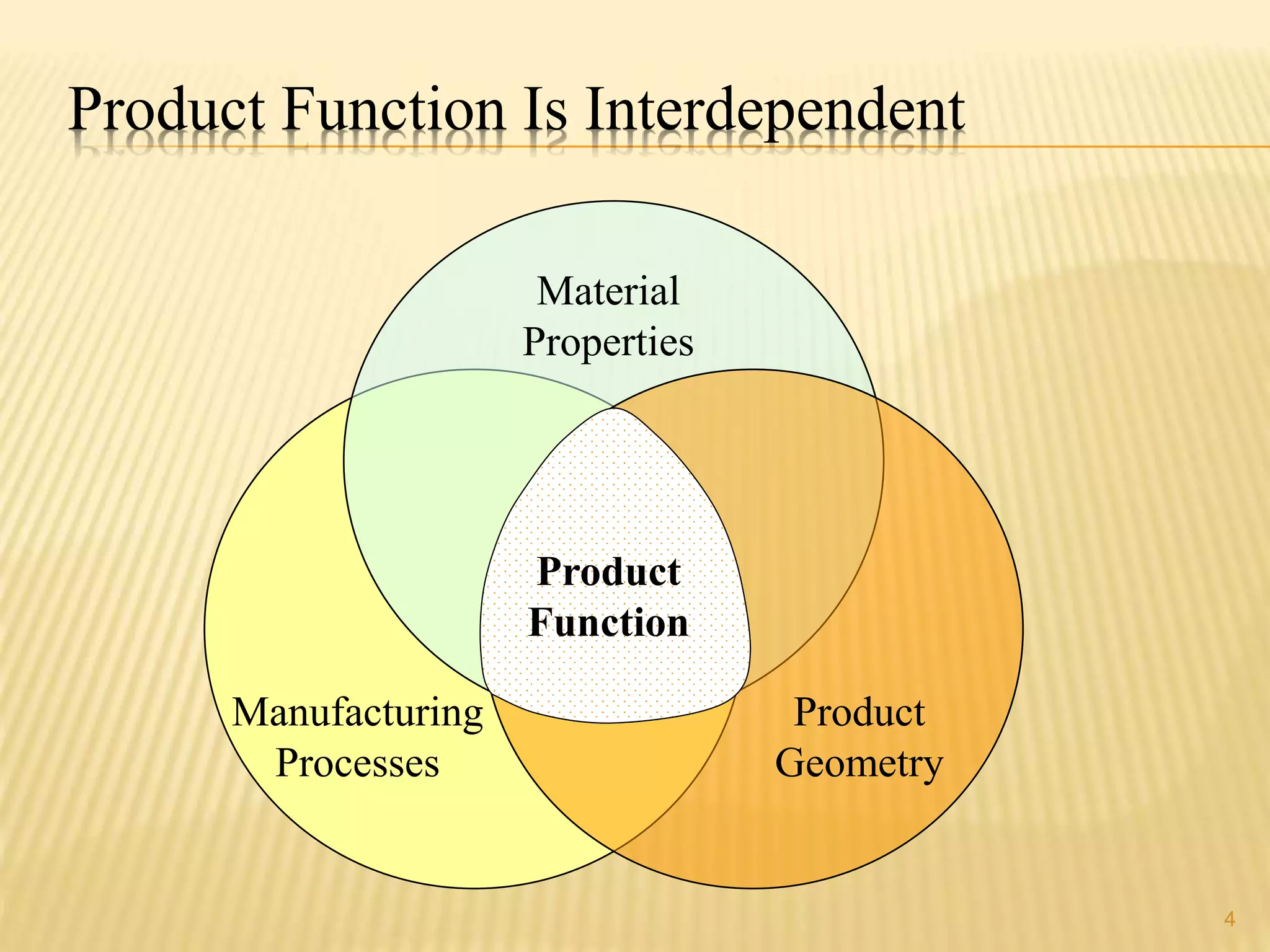

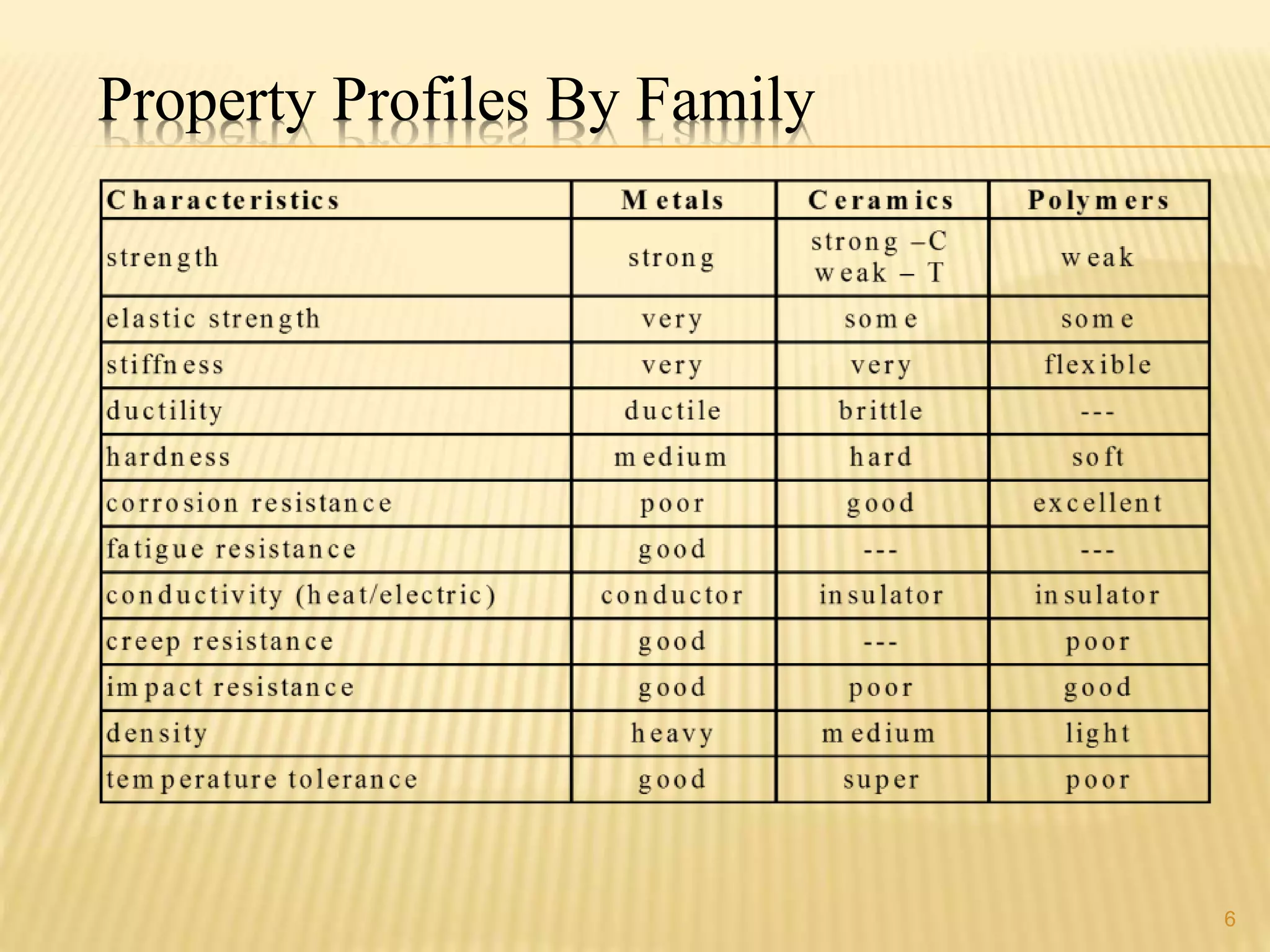

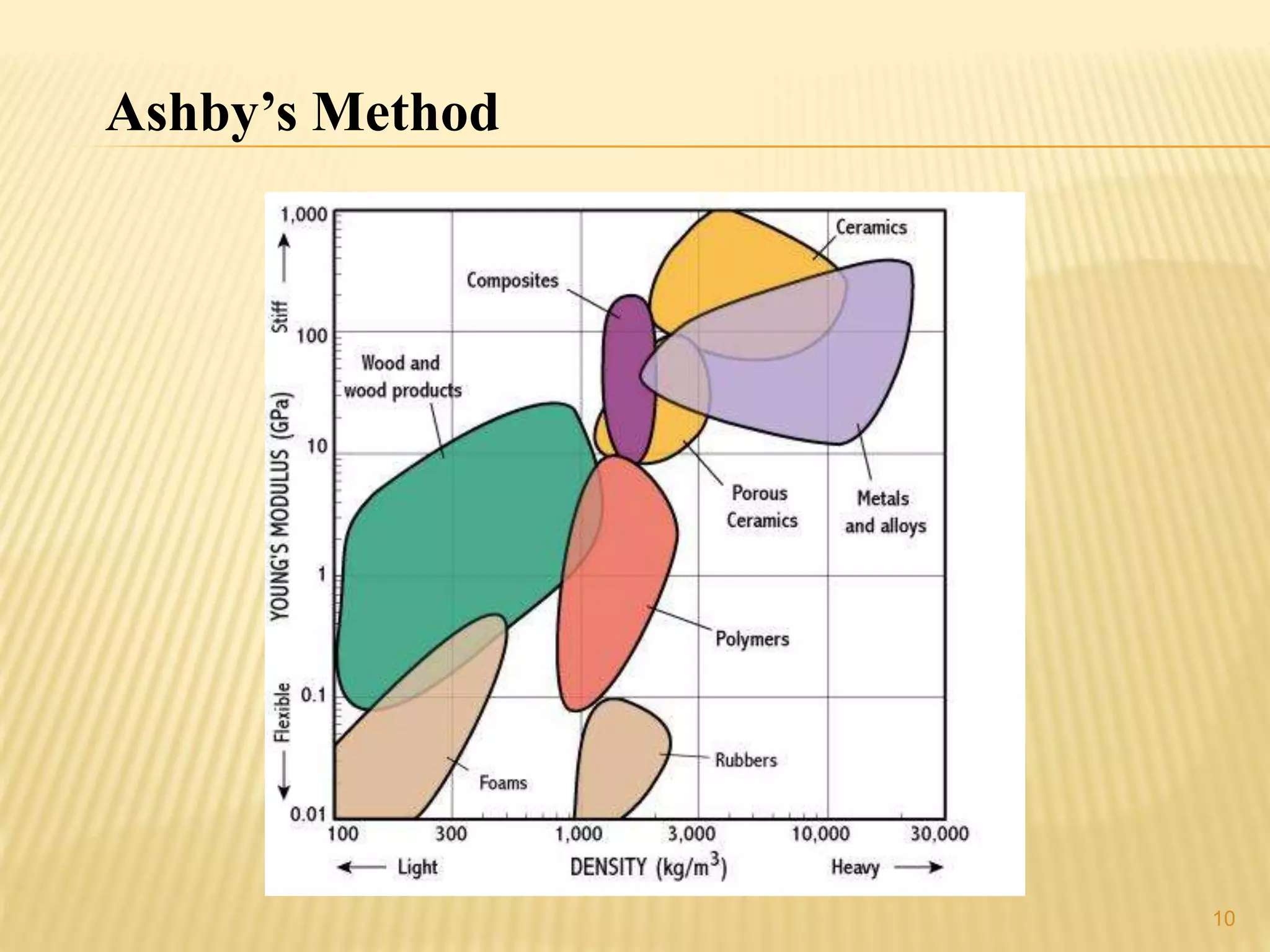

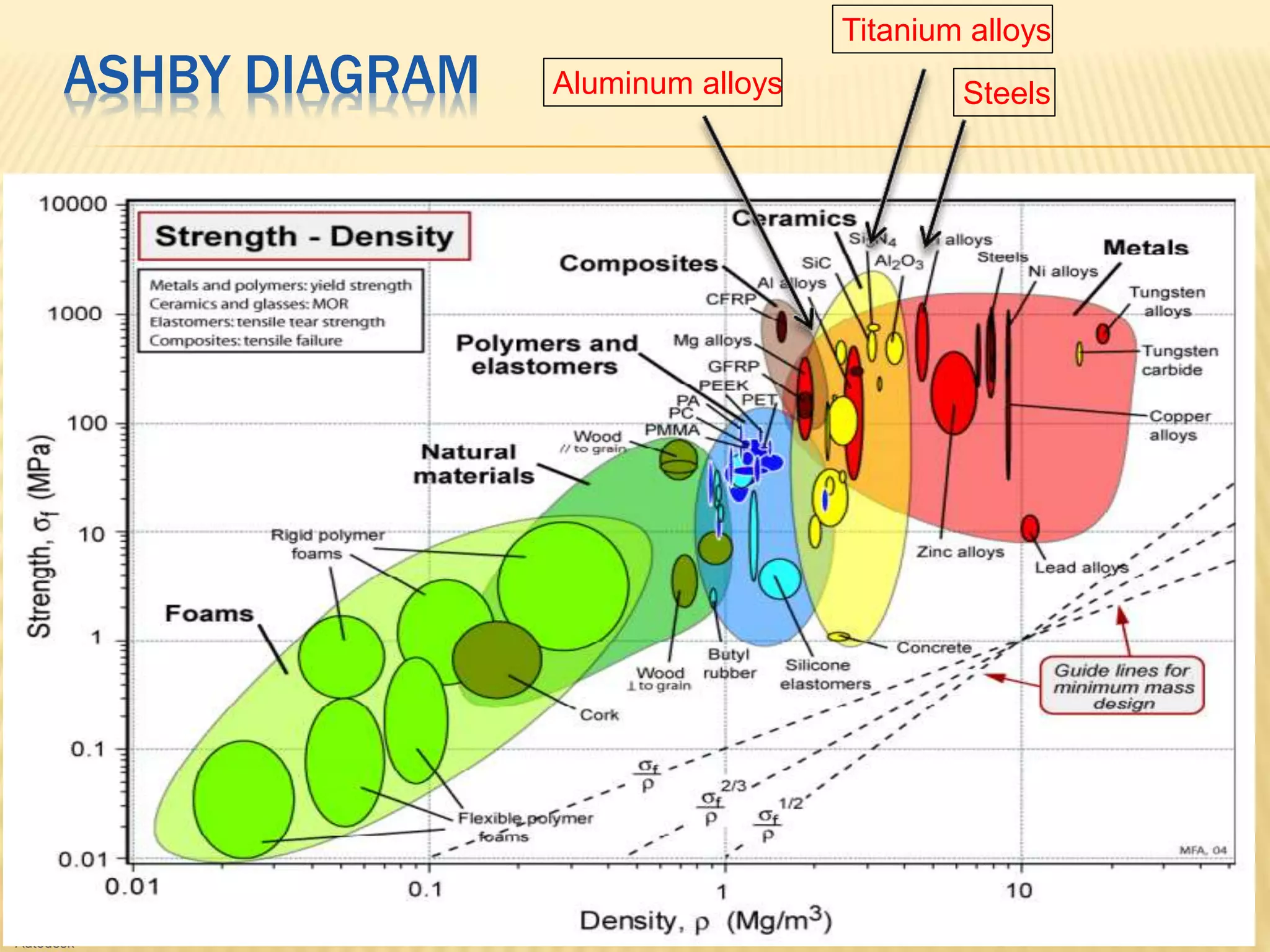

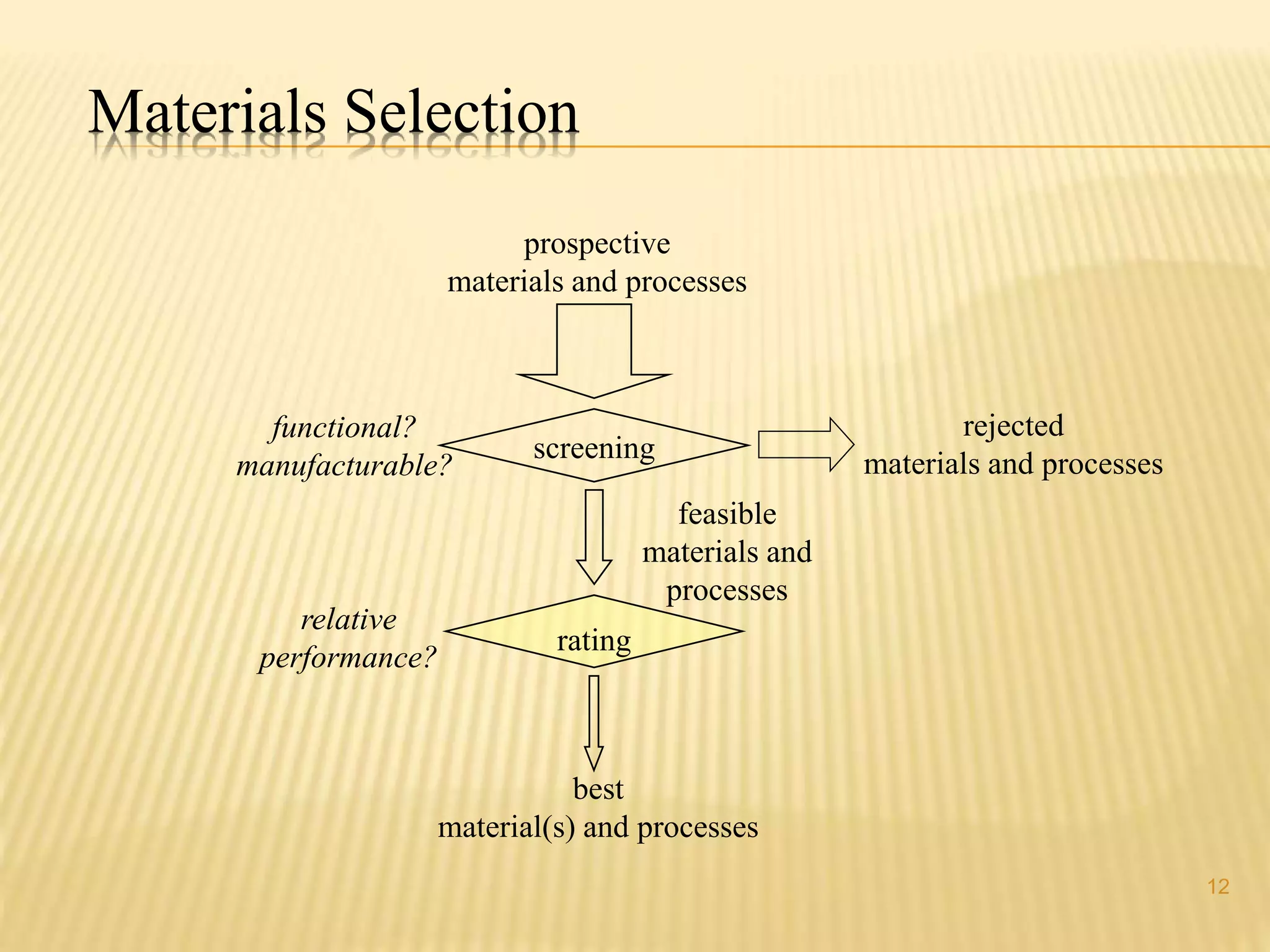

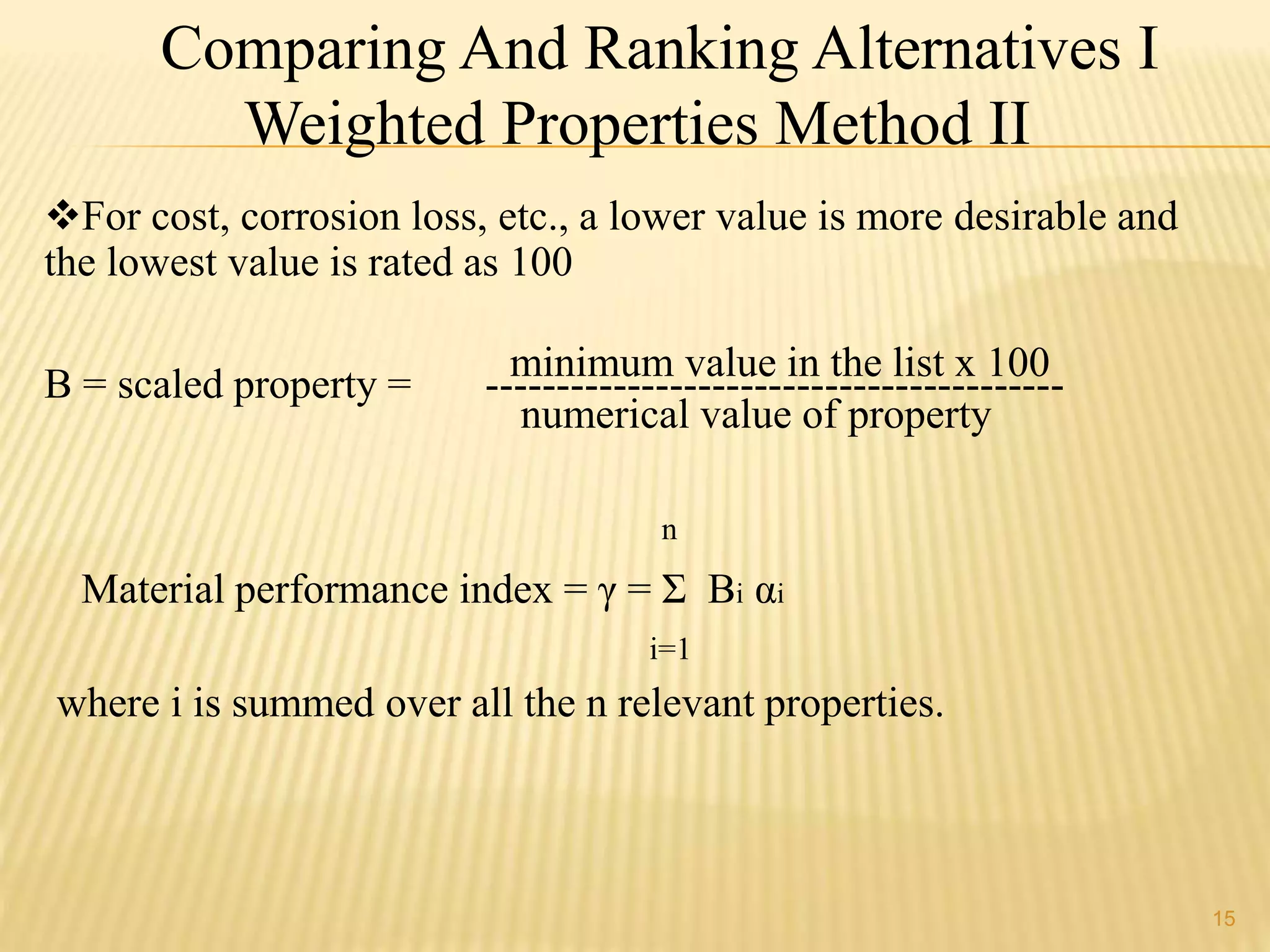

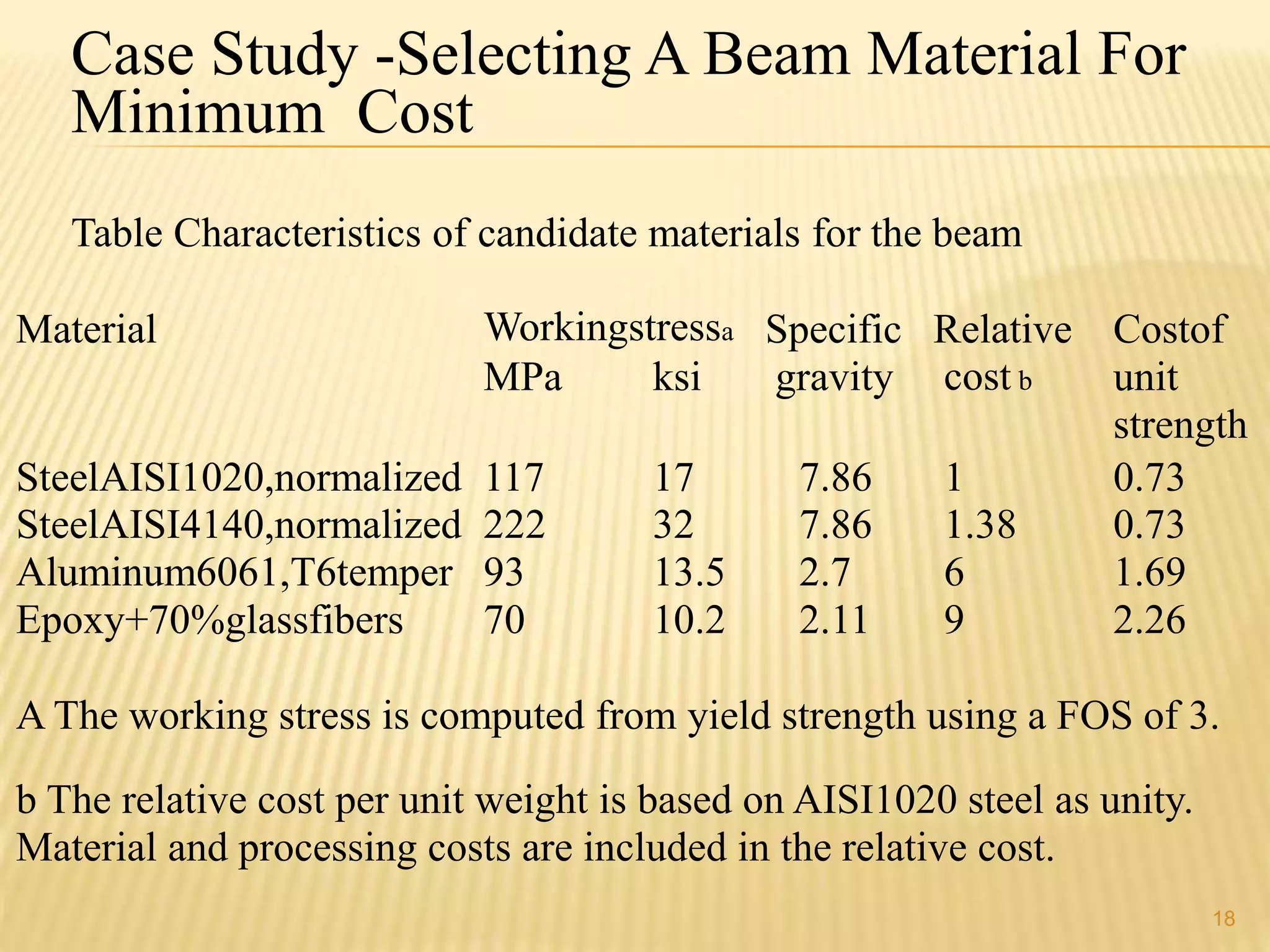

The document discusses the materials selection process for choosing an optimal material for a given component. It outlines the general steps as: 1) analyzing performance requirements, 2) developing alternative solutions, 3) evaluating solutions, and 4) deciding on the best solution. Key aspects of the process include identifying material properties needed to meet functional, manufacturing, reliability, and service condition requirements. Multiple potential materials and manufacturing processes are considered to find the best combination that will allow the component to fulfill its intended purpose. Evaluation and selection methods like weighted properties, material indices, and case studies are presented.