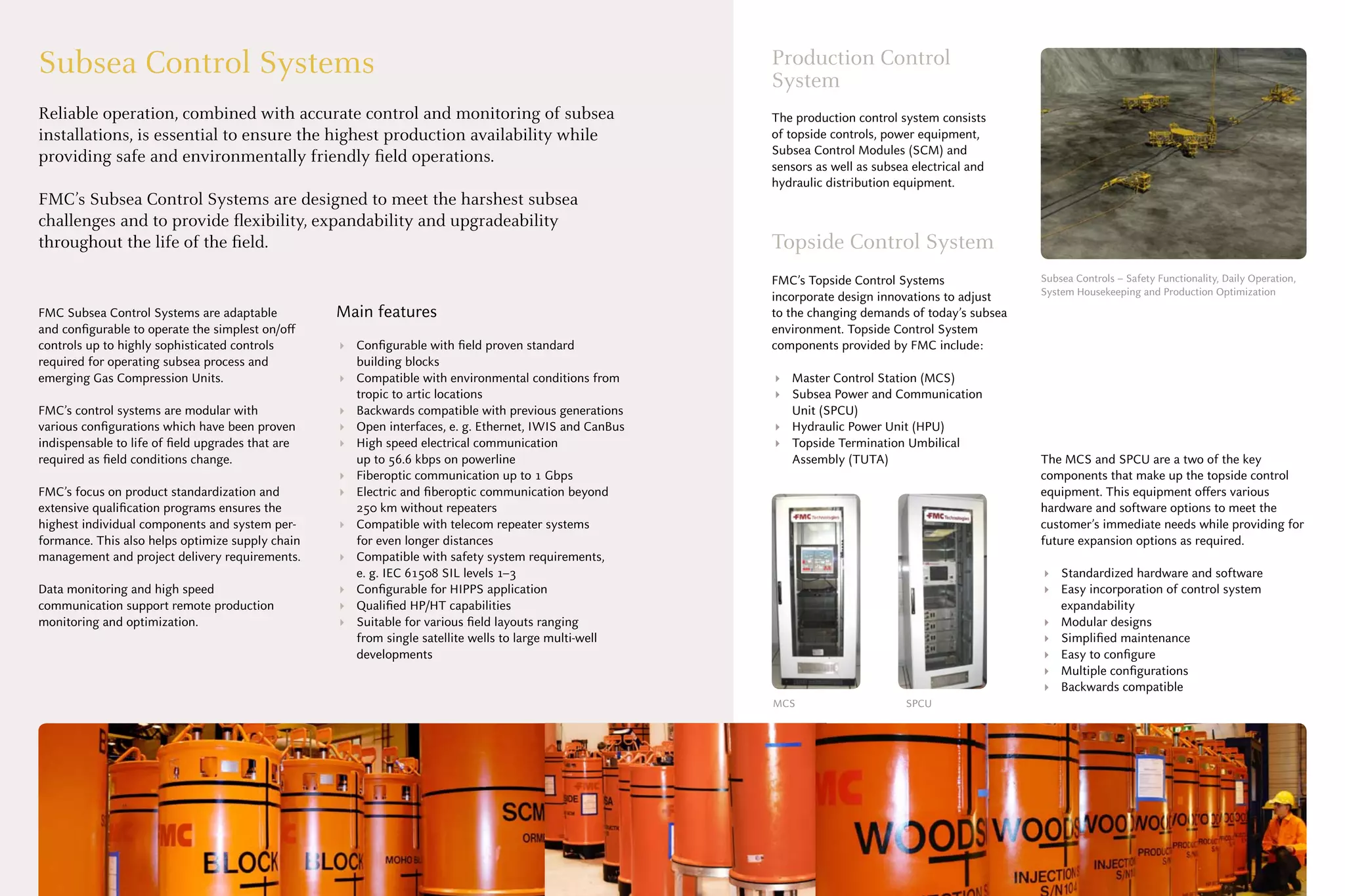

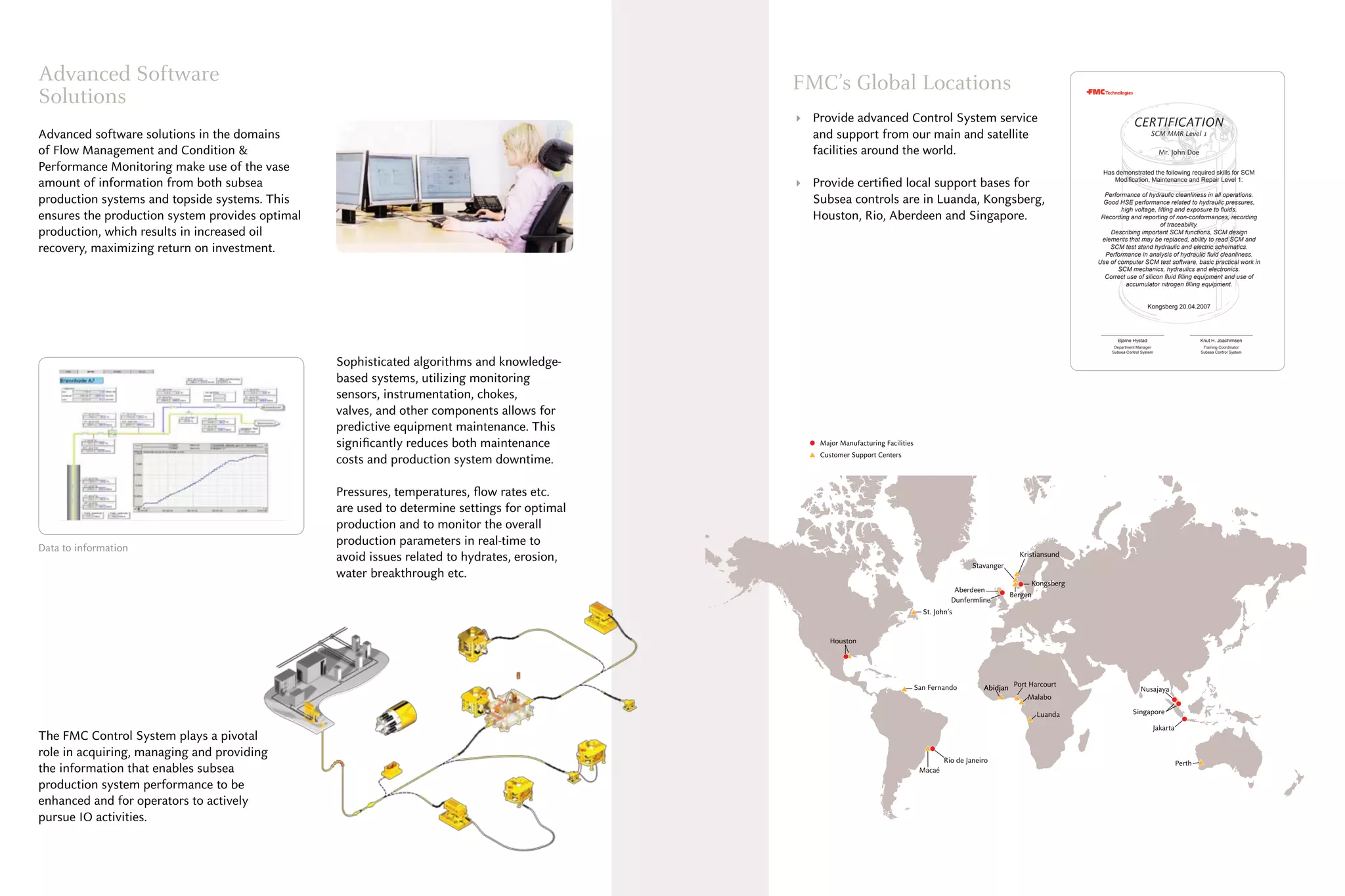

FMC's subsea control systems are designed to reliably control subsea installations through accurate monitoring and control, ensuring high production availability while operating safely. The systems are modular and configurable to meet a range of control complexity, from simple on/off controls to sophisticated process controls. Key components include subsea control modules, topside control systems, and distribution systems. The document provides details on FMC's control system capabilities and components.