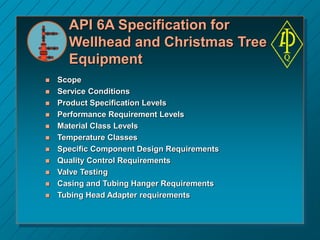

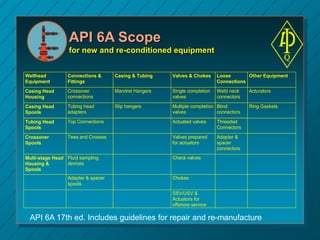

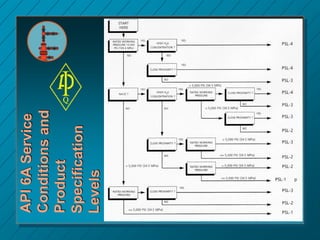

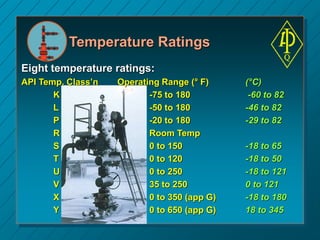

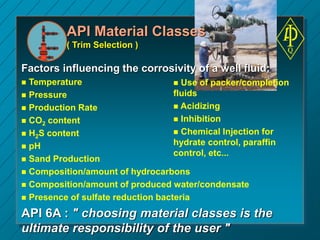

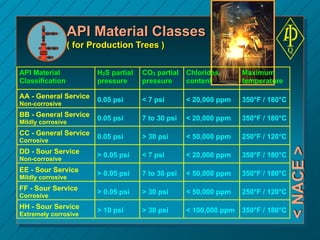

This document provides an overview of API 6A, which establishes specifications for wellhead and Christmas tree equipment. It covers the scope of equipment covered, service conditions, material classes, pressure and temperature ratings, quality control requirements, and testing procedures. Equipment manufactured according to API 6A has undergone audits and testing to ensure it can withstand downhole conditions in the oil and gas industry.