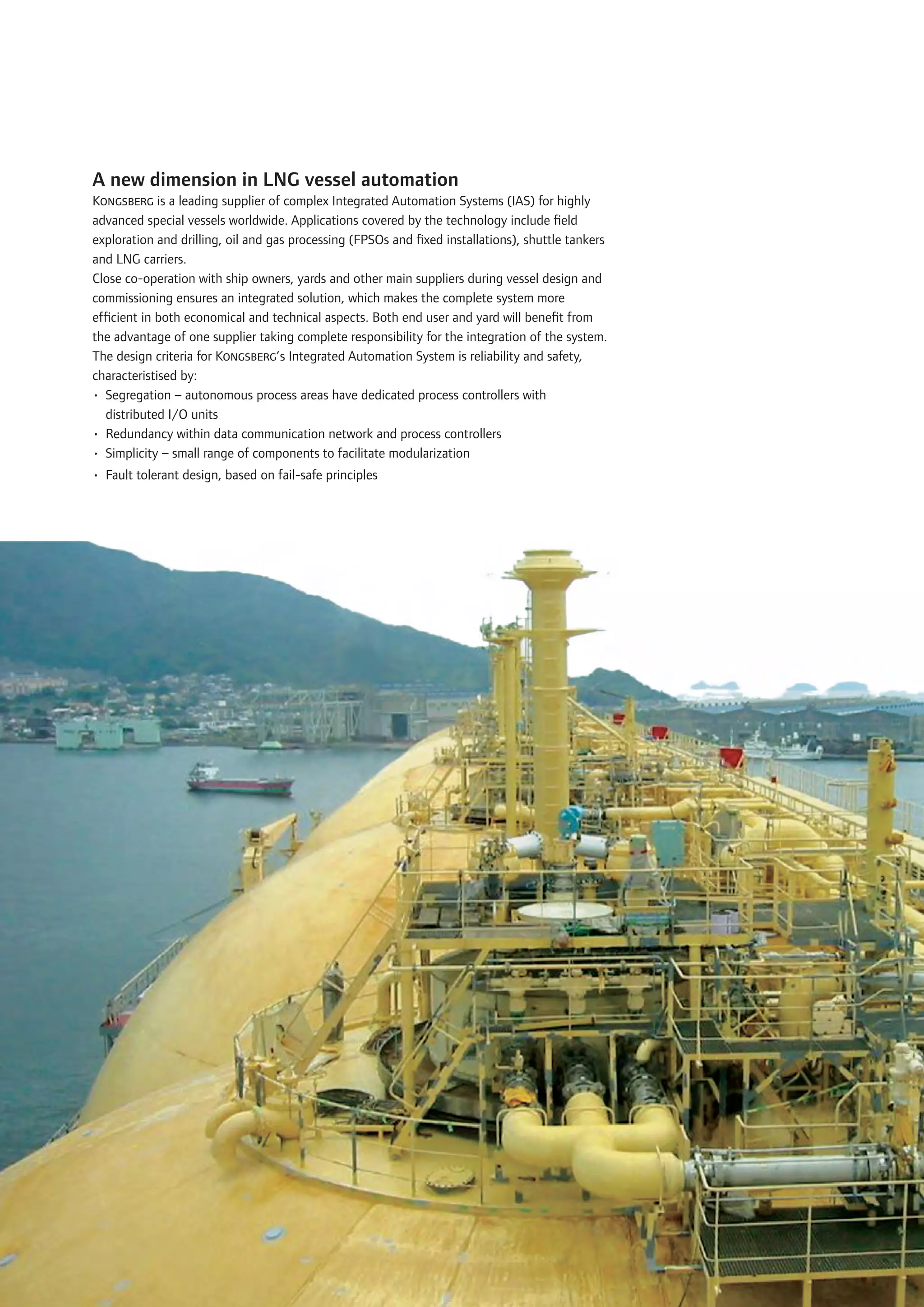

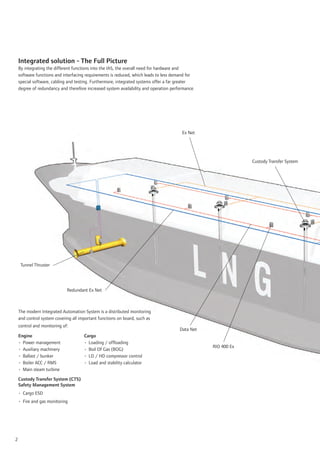

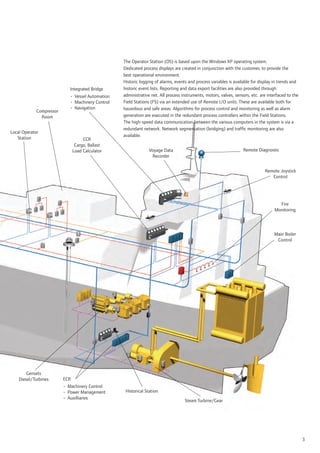

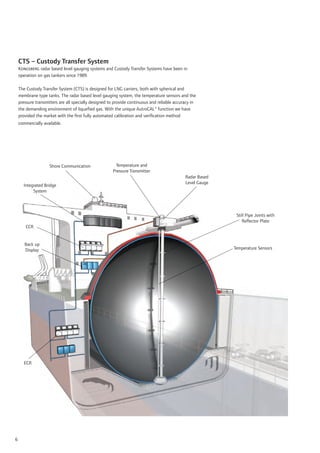

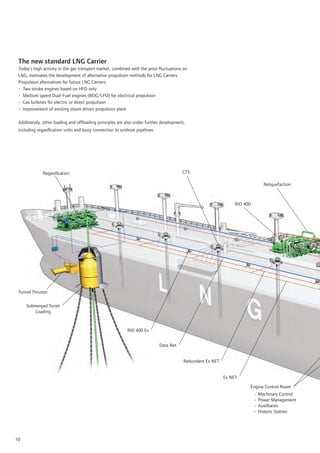

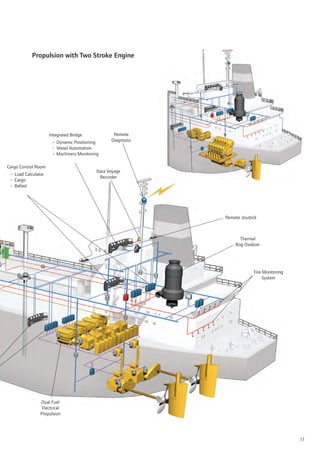

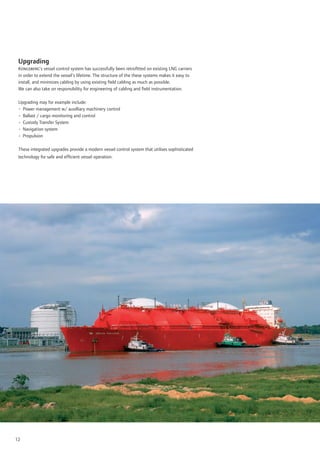

This document discusses Kongsberg's integrated automation systems (IAS) for vessels like LNG carriers. The IAS provides integrated monitoring and control of vessel functions including cargo handling, machinery, navigation, and more. It ensures safety and reliability through features like redundancy, segregation of systems, and fault tolerance. The IAS can also integrate additional functions for cargo operations, simulation, engineering services, and upgrading existing vessels.