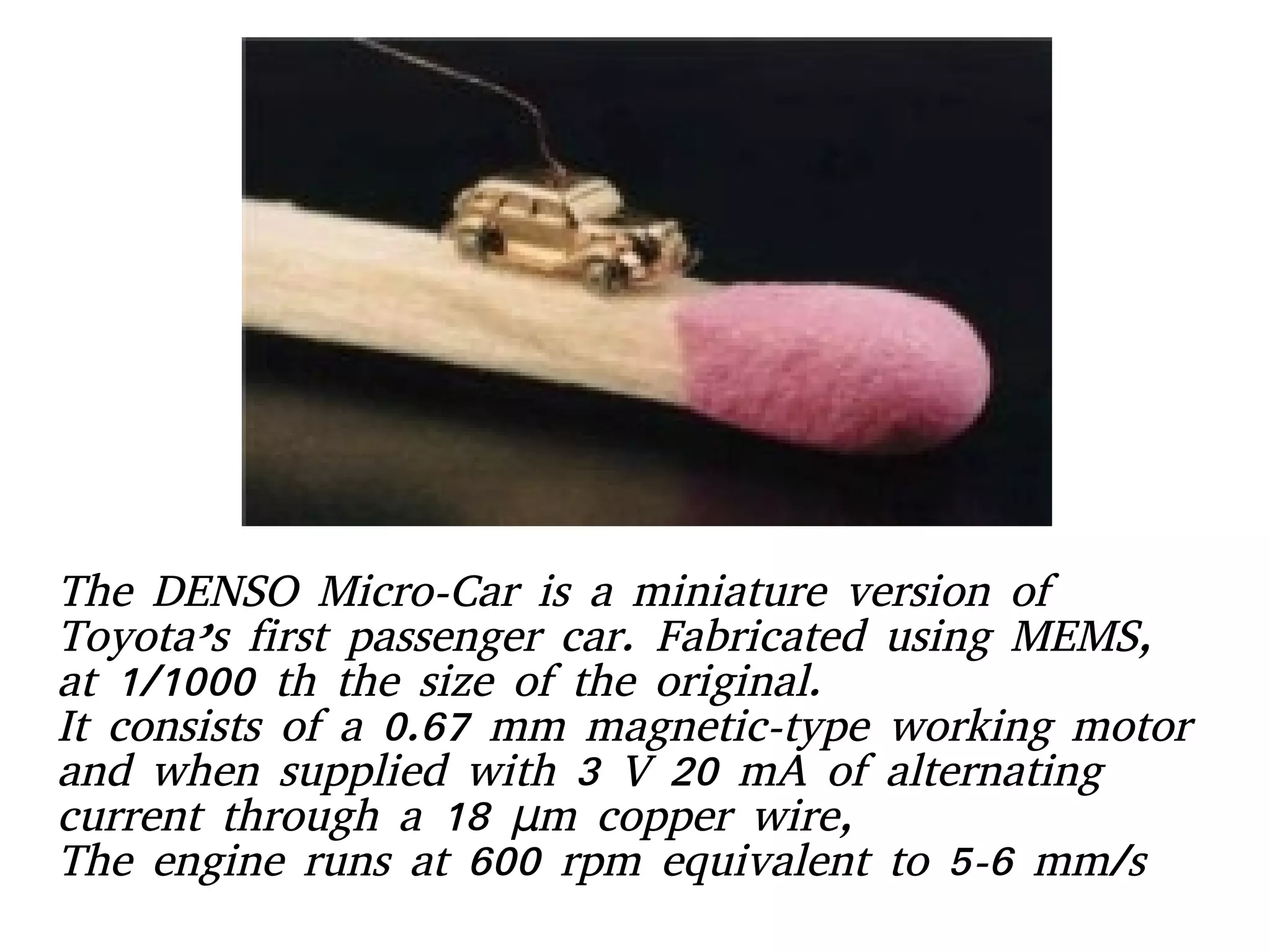

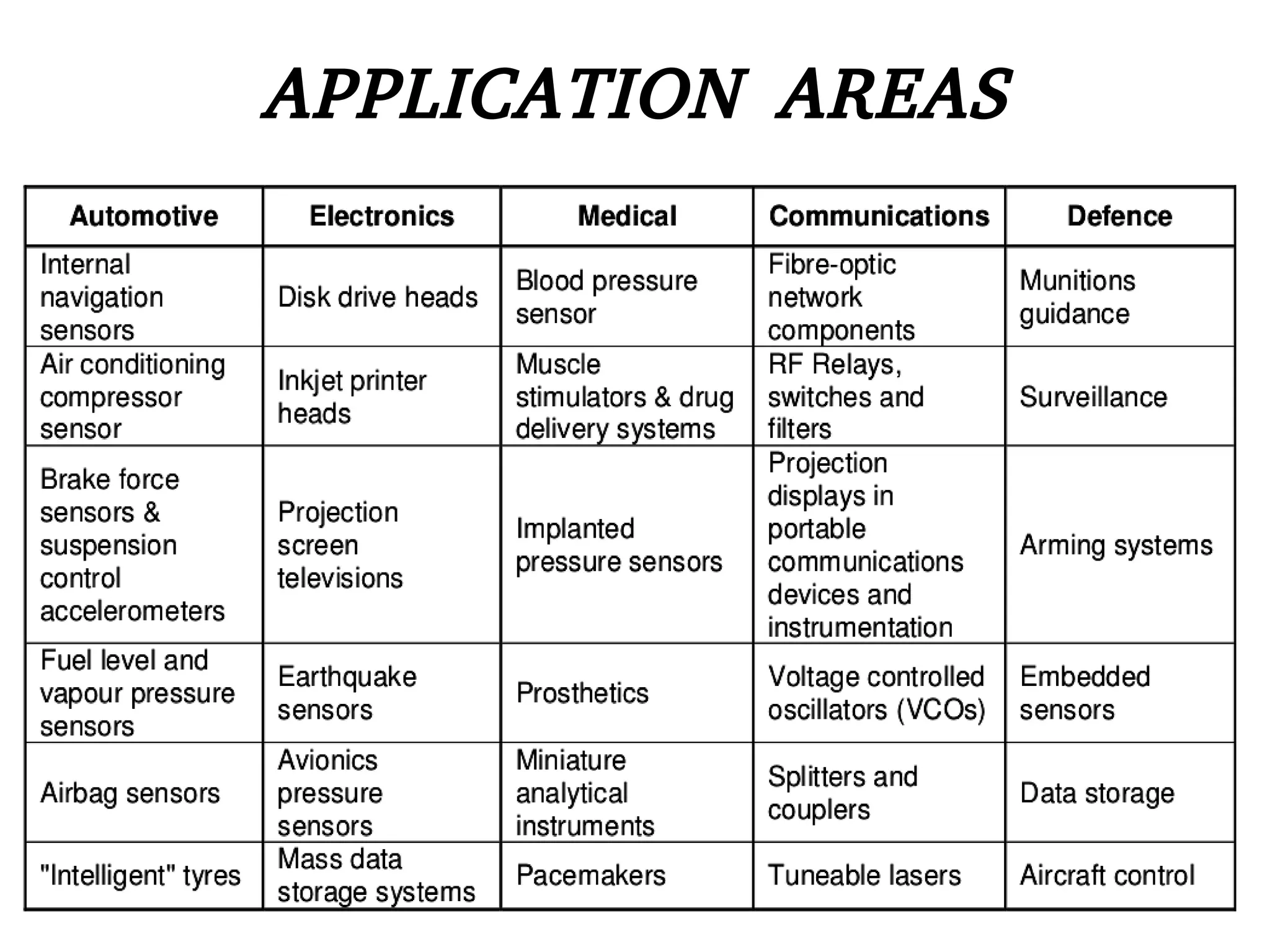

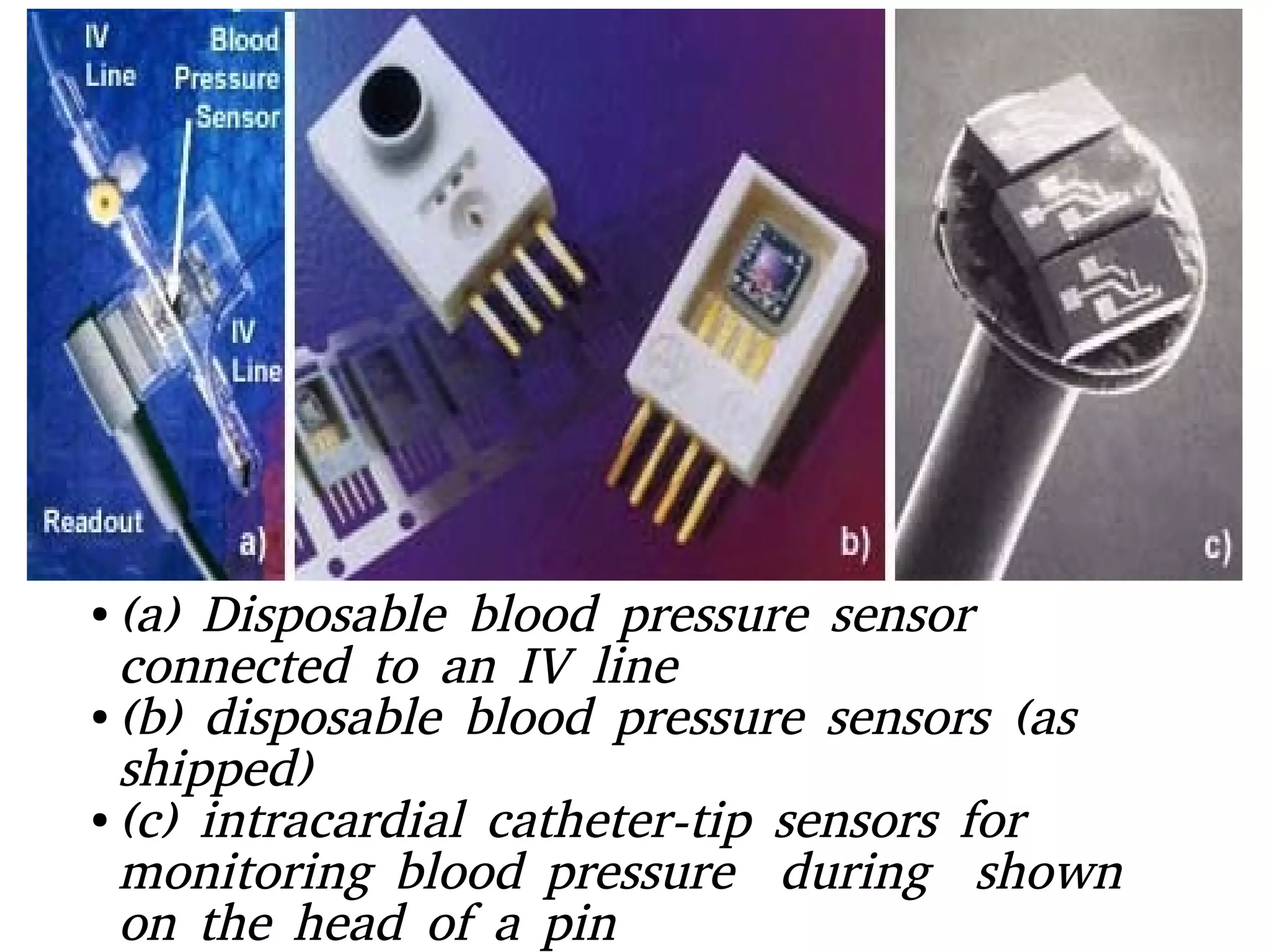

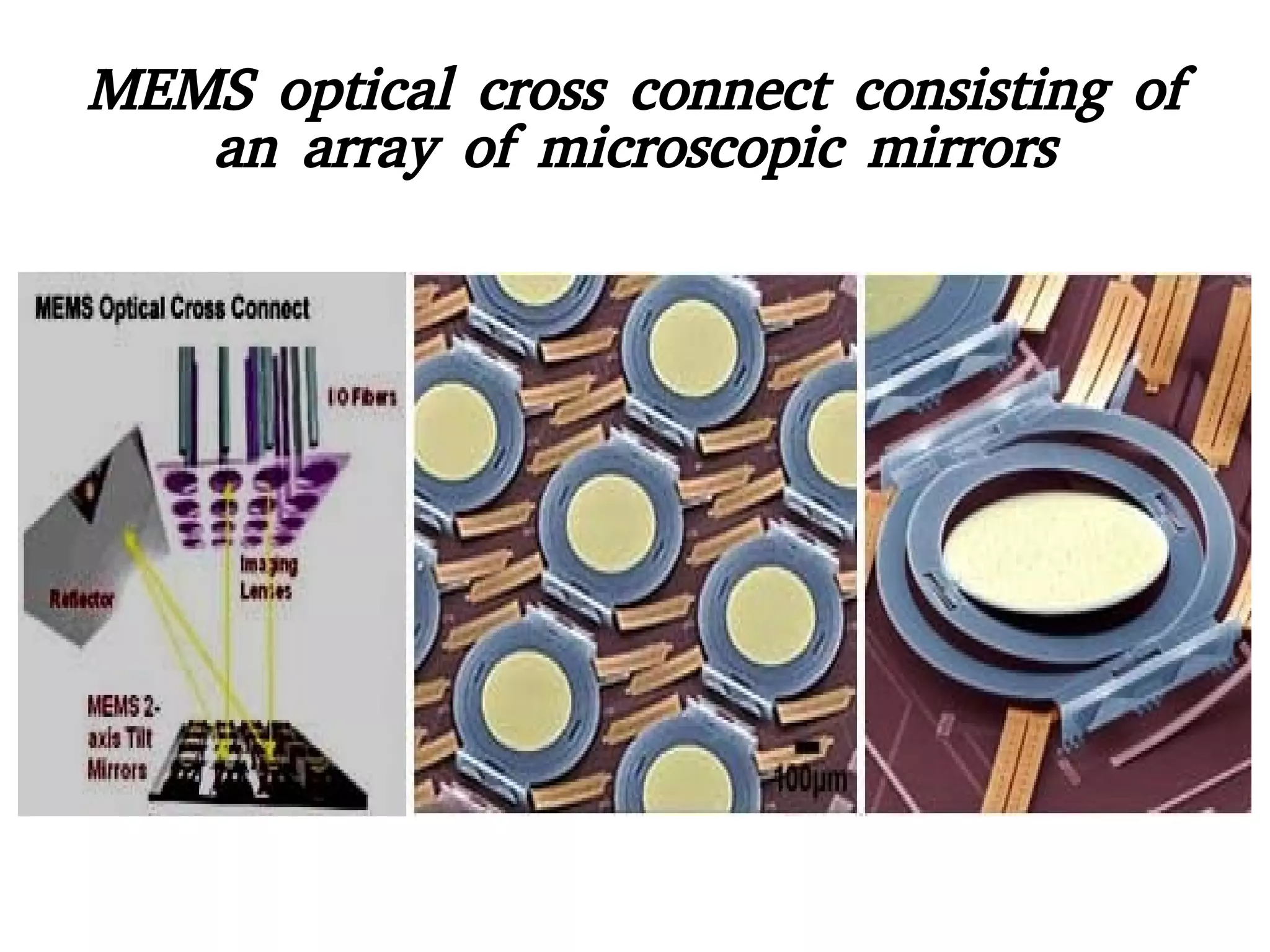

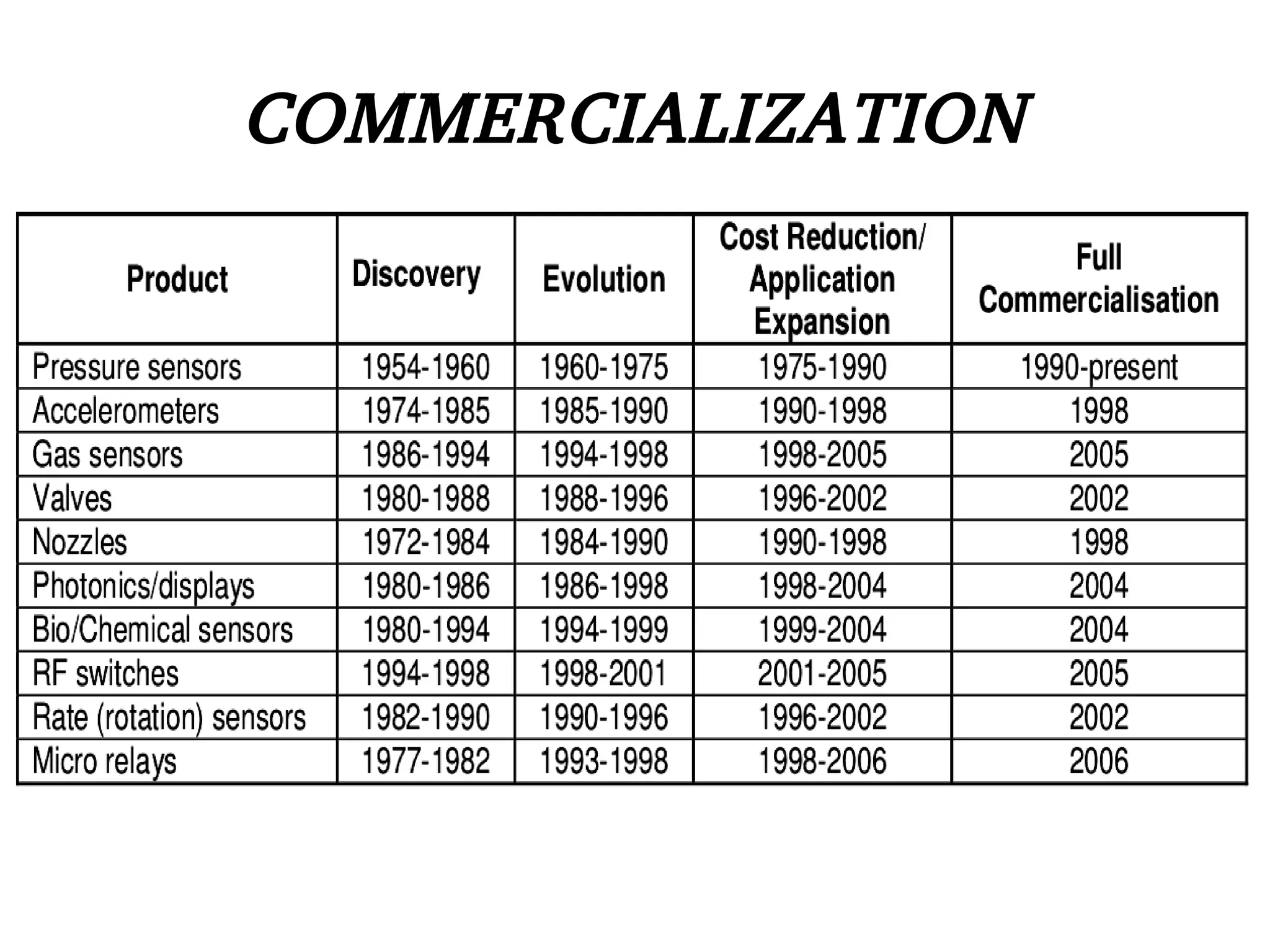

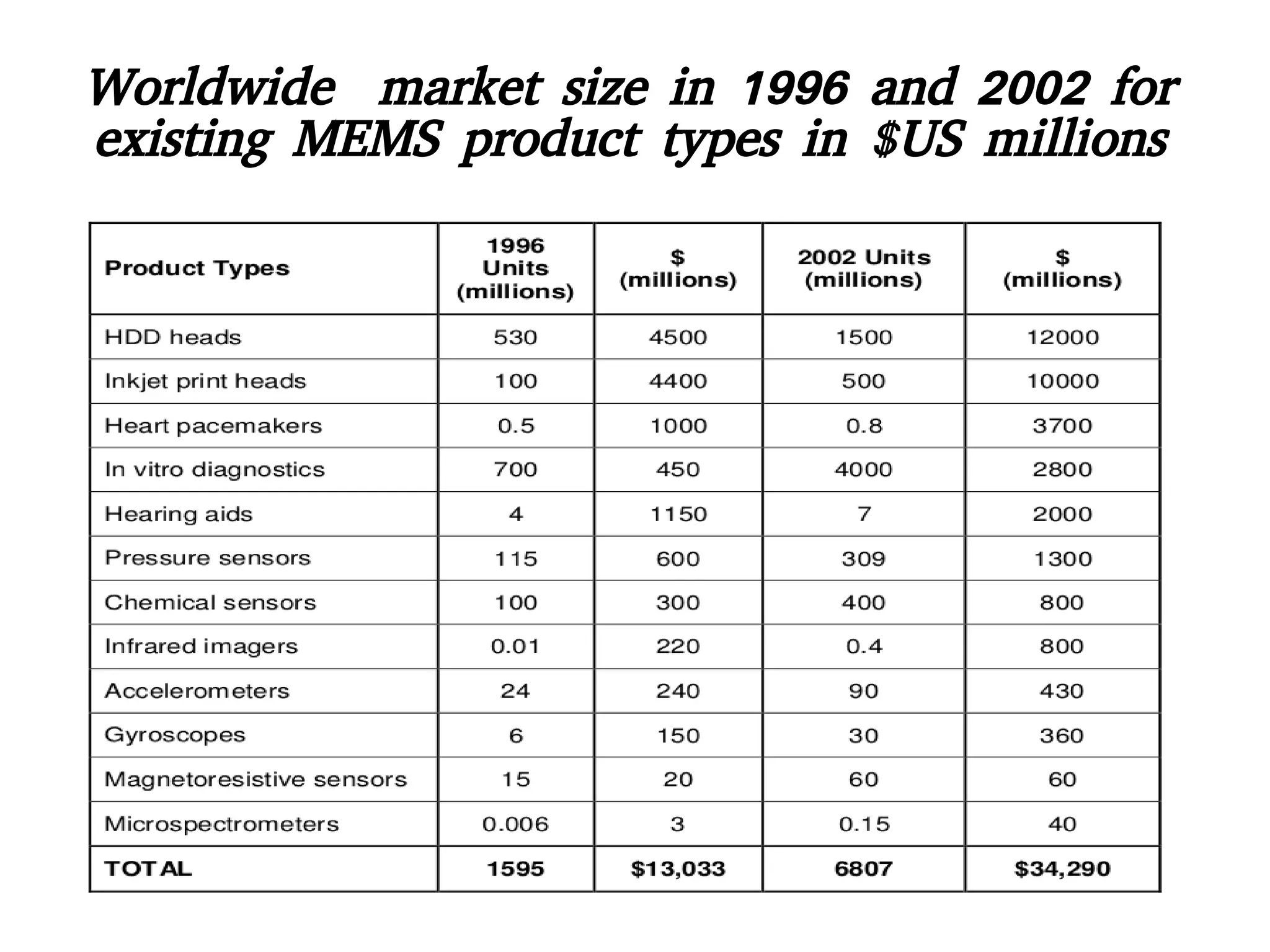

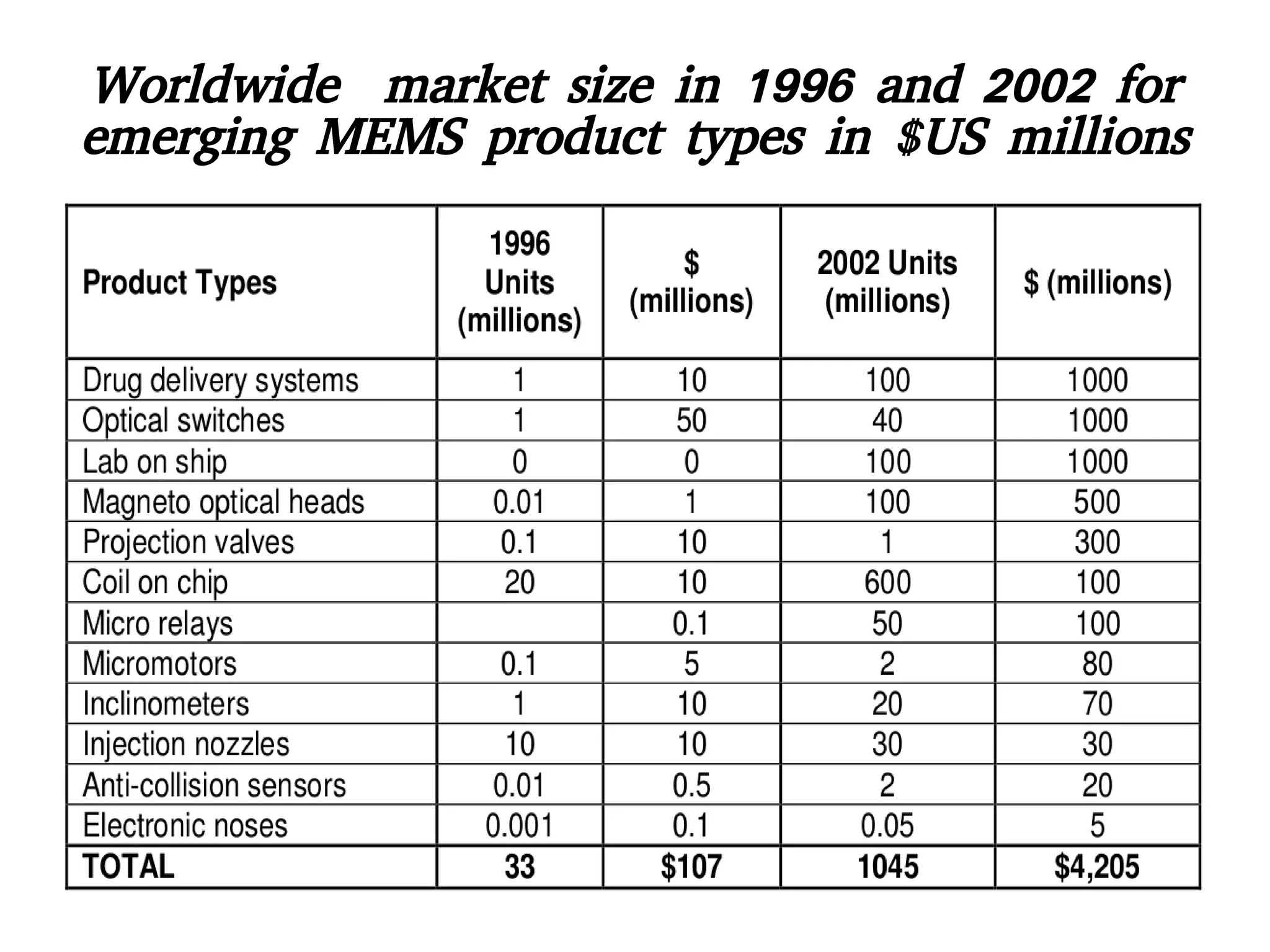

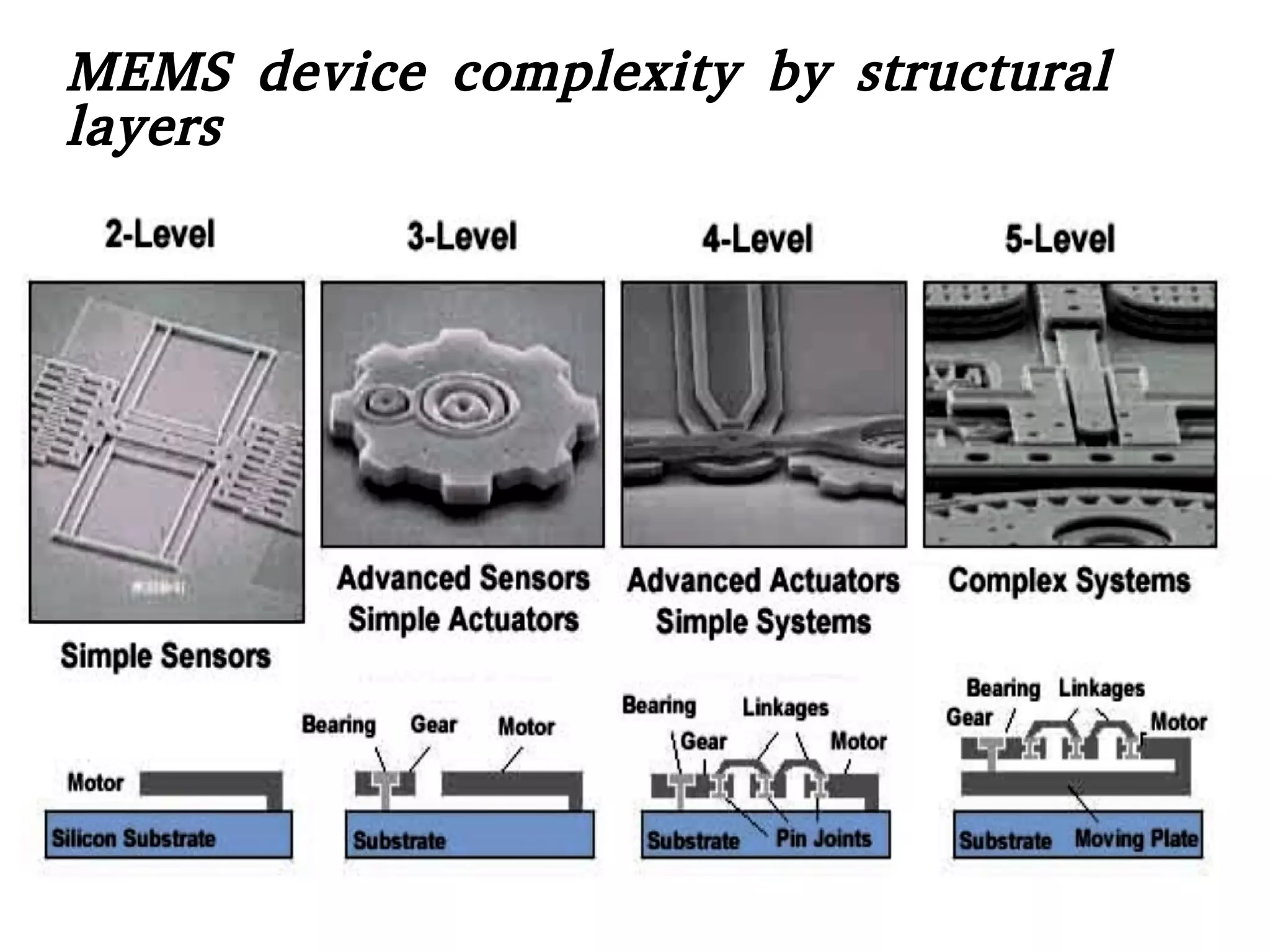

The document discusses Micro-Electro-Mechanical Systems (MEMS), which is a technology that creates tiny integrated devices combining mechanical and electrical components, ranging in size from micrometers to millimeters. As an example, it describes the DENSO Micro-Car, a miniature version of Toyota's first passenger car fabricated at 1/1000 the size using MEMS. It also provides information on MEMS applications, commercialization, fabrication methods, and industry challenges.