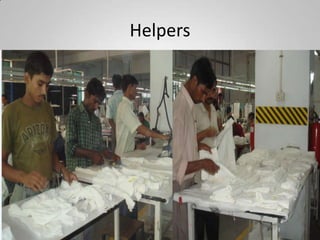

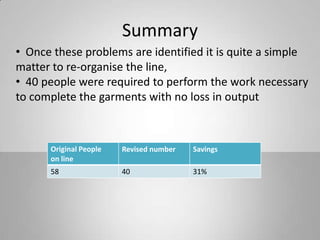

The document discusses a case study of improving productivity through work study methods in a garment factory. It identifies several issues with the current production line including lack of space between workers, low work-in-progress levels, and helpers working outside the line. It then describes how reorganizing the line layout, incorporating all tasks within the line, and properly balancing workloads allowed the same output to be achieved with 40 workers instead of 58, resulting in a 31% increase in productivity. The document notes these principles can benefit both small and large order factories.