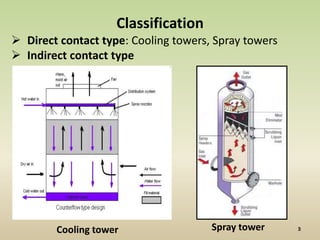

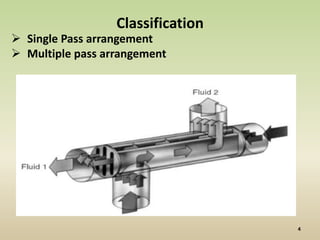

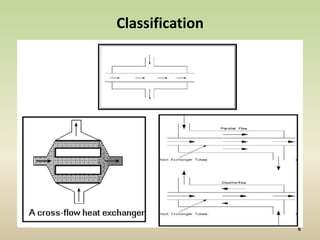

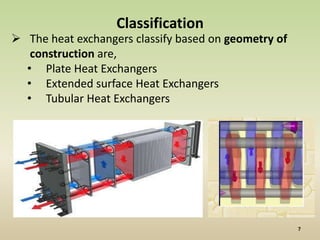

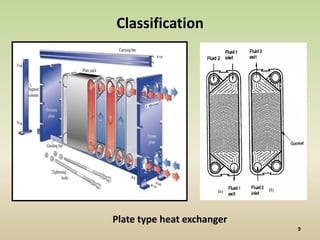

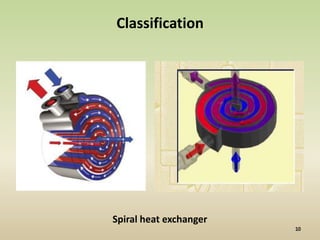

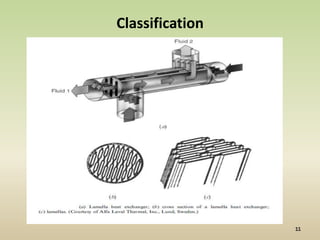

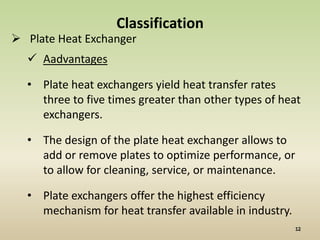

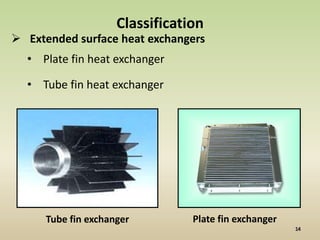

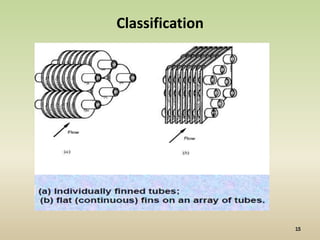

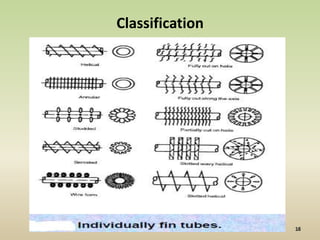

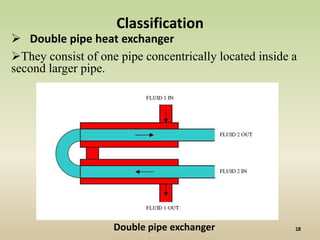

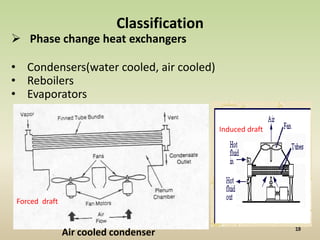

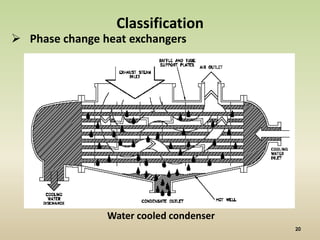

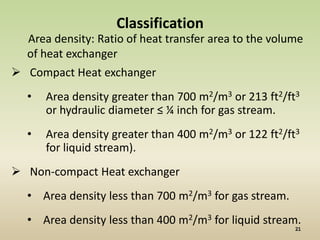

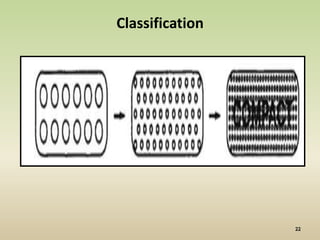

The document describes a double pipe heat exchanger and provides classifications of heat exchangers. A double pipe heat exchanger consists of two concentric pipes and connecting tees to transfer thermal energy between two fluids. Heat exchangers can be classified based on their heat transfer mechanism, construction type, flow arrangement, number of passes, and operating temperatures and pressures. Common types include plate, tubular, extended surface, and phase change heat exchangers.