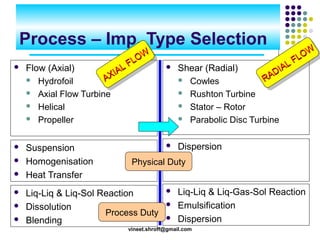

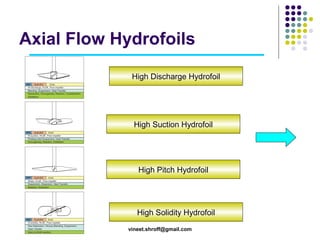

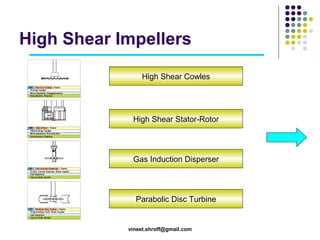

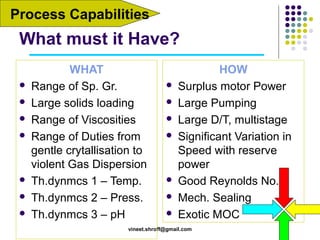

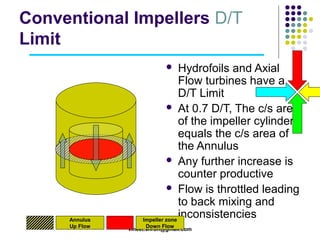

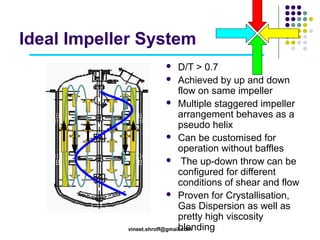

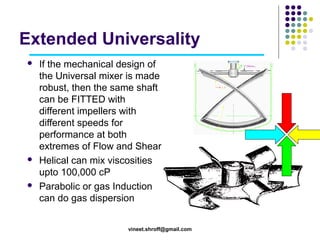

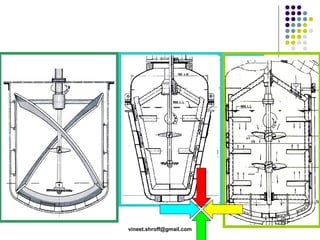

The document discusses agitator design and selection. It describes single duty agitators that provide either flow or shear, and multi-duty agitators. The selection of impeller type, diameter, and speed depends on the process requirements. Impeller options include axial flow, radial flow, and combinations. Proper agitator design also considers mechanical design aspects like power requirement, shaft, and seals. A universal mixer is described that can handle a wide range of mixing duties through adjustable flow and shear.