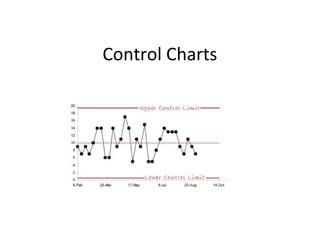

Control charts

- 2. GE6757- Total Quality Management Control Charts Prepared By, V.Sutha Jebakumari, AP/CSE L.Shanmuga Priya, AP/CSE, Kamaraj College of Engineering & Technology, Virudhunagar.

- 3. Control Charts • Walter Shewhart first utilized control charts in 1924 to aid the world of manufacturing. Control charts have two general uses in an improvement project. • The most common application is as a tool to monitor process stability and control.

- 4. Control Charts • “No matter how well the process is designed, there exists a certain amount of nature variability in output measurements.“ • A control chart tells us how much variation the process causes. • A stable process produces predictable results consistently. An example of a control chart that shows an unstable process means variables affected must be analyzed and controlled before the improvement process can begin.

- 5. Types of control charts • There are two types of control charts; those that analyze attributes and those that look at variables in a process or project. Examples of a control chart include: • X-Bar & R Control Charts • X-Bar & S Control Charts • U Charts • P Control Charts • C Control Charts

- 6. Examples of Control Charts • U Charts – These variable types of control charts utilize an upper and lower range. Elements falling in the upper range need attention and analysis in order for the problem to be corrected. • X-Bar & R Charts – These variable charts utilize the X-Bar or the Mean to determine subgroups. The R or Range plots the subgroups based on upper and lower control limits. X-Bar & R Charts are the most widely utilized charts in project management, however, are only successful if 5 or less subgroups are analyzed. • X-Bar & S Charts – Using this example of a variable control chart is effective for 5 or more subgroups and the S or Standard Deviations are considered in both upper and lower control limits based on the X-Bar or Mean. • p Control Charts – This attribute-type chart is effective when elements are not equal. A p Control Chart might be used to determine how many accidents occur each day at a chosen intersection. • c Control Charts – Another attribute-type control chart, the c Control Chart explores elements that are nonconforming. A c Control Chart might be used to explore mass-production of one similar product where the elements per unit do not conform to the norm.

- 7. Two causes of fluctuation • Most examples of a control chart considers two causes of fluctuation, common causes and special causes.

- 8. Three categories of variation 1. Within piecewise variation(eg. Roughness of a piece) 2. Piece to piece variation (light intensity of four bulbs produced from a machine will be different) 3. Time to time variation (difference in product produced at different times of the day)

- 9. Second categories of variation Variation is due to a combination of 1.Equipment 2.Materials 3.Environment 4.Operator

- 10. 1. Equipment • Source includes tool wear, machine vibrations and electrical fluctuations. • Even identical machines will have different capabilities. • It becomes crucial when scheduling the manufacture of critical parts.

- 11. 2. Material • Because variation occurs in the finished product, it must also occur in the raw material. • Quality characteristics as tensile strength, ductility, thickness, porosity and moisture content can be expected to contribute to the overall variation in the final product.

- 12. 3. Environment • Temperature, light, radiation, particle size, pressure and humidity all can contribute to variation in the product. • Experiments are conducted in outer space to learn more about the effect of the environment on product variation.

- 13. 4. Operator • The source of variation includes the method by which the operator performs the operation. • The operator’s physical and emotional well- being contribute to the variation. • A cut finger, a personal problem or a headache can make an operator’s quality performance vary.

- 14. Elements of a Control Chart • A control chart begins with a time series graph. • A central line (X) is added as a visual reference for detecting shifts or trends – this is also referred to as the process location. • Upper and lower control limits (UCL and LCL) are computed from available data and placed equidistant from the central line. This is also referred to as process dispersion. •

- 16. • Control limits (CLs) ensure time is not wasted looking for unnecessary trouble – the goal of any process improvement practitioner should be to only take action when warranted. Control limits are calculated by: • Estimating the standard deviation, σ, of the sample data • Multiplying that number by three • Adding (3 x σ to the average) for the UCL and subtracting (3 x σ from the average) for the LCL • Mathematically, the calculation of control limits looks like: •

- 17. Run Charts • Monitor the performance of one or more processes over time to detect trends, shifts or cycles. • Allow us to compare a performance measure before and after implementation of a solution to measure its impact. • Focuses attention on truly vital changes in the process. • Assess whether improved performance has been sustained.

- 18. How to Create a Run Chart There are seven steps to creating a run chart. • Decide on the measure to be analyzed (assuming there is a reliable measurement system in place). • Gather the data – have a minimum of 10 data points. • Draw a graph with a vertical line and a horizontal line. • On the vertical line, or the y-axis, draw the scale relative to the variable you are measuring. • On the horizontal line, or the x-axis, draw the time or sequence scale. • Calculate the mean/median (whichever the data set indicates to be appropriate) and draw a horizontal line at that value – going across the graph. • Plot the data in the sequence, or the time order, in which the data was collected.

- 19. Characteristics of a run chart • On the X axis you have data in some sort of chronological order e.g. Jan, Feb, Mar • On the Y axis you have the measure of interest e.g. %, count • Once the data points are connected you put a centre line (CL) between the graph. For a run chart the CL is called the Median.

- 20. Interpreting a run chart • There are four rules that can be used to interpret a run chart. Non-random variation can be recognized by looking for: • Rule 1 – Shift Six or more consecutive points either all above or all below the centre line (CL). Values that fall on the CL do not add to nor break a shift. Skip values that fall on the median and continue counting.

- 21. Rule 1 – Shift

- 22. Rule 2 – Trend • Five or more consecutive points all going up or all going down. If the value of two or more successive points is the same (repeats), ignore the like points when counting.

- 23. Rule 2 – Trend

- 24. Rule 3 – Too many or too few runs • A non-random pattern is signalled by too few or too many runs, or crossings of the median line. If there are too many or too few runs, this is a sign of non-random variation. An easy way to count the number of runs is to count the number of times the line connecting all the data points crosses the median and add one. If the number of runs you have are: • Within the range outlined in the table, then you have a random pattern. • Outside the range outline in the table, then you have a non-random pattern or signal of change.

- 25. Too many or too few runs

- 26. Rule 4 – An astronomical data point • This is a data point that is clearly different from all others. Different people looking at the same graph would be expected to recognize the same data point as astronomical.

- 27. Rule 4 – An astronomical data point

- 28. Rule 4 – An astronomical data point By applying each of the four rules, you can evaluate the run chart for a signal for change (through a non- random variation). However, it is not necessary to find evidence of change with each of the four rules to determine that a change has occurred. Any single rule occurring is sufficient evidence of a non-random signal of change.

- 29. Benefits of Run Charts The following are a few benefits of a run chart: • Easy to draft. • Easy to analyze and interpret. • Does not require much technical skill. • Straightforward representation of data.