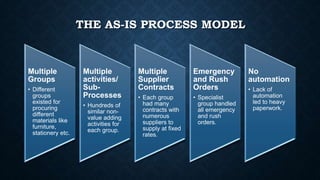

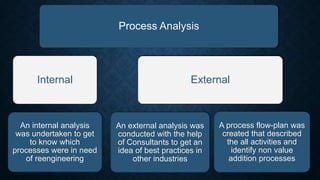

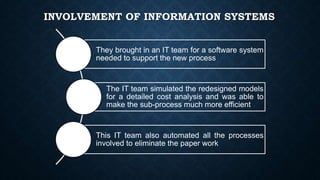

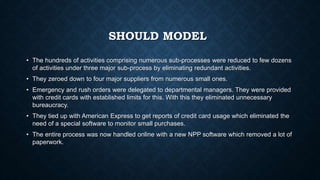

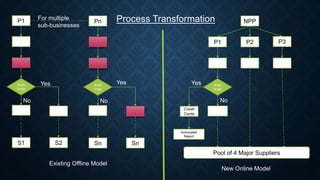

Xerox was spending $4.3 billion annually on non-production procurement (NPP). To reduce costs, Xerox used business process reengineering to analyze and redesign the NPP process. A cross-functional team mapped the existing process and identified inefficiencies. The as-is process had multiple groups procuring different materials, hundreds of redundant activities, numerous supplier contracts, and a specialist group for emergencies. The redesigned process streamlined activities under three sub-processes, reduced suppliers to four major ones, and gave department managers credit cards for emergencies. An information systems team automated the entire process and connected it to American Express for reporting, removing paperwork.