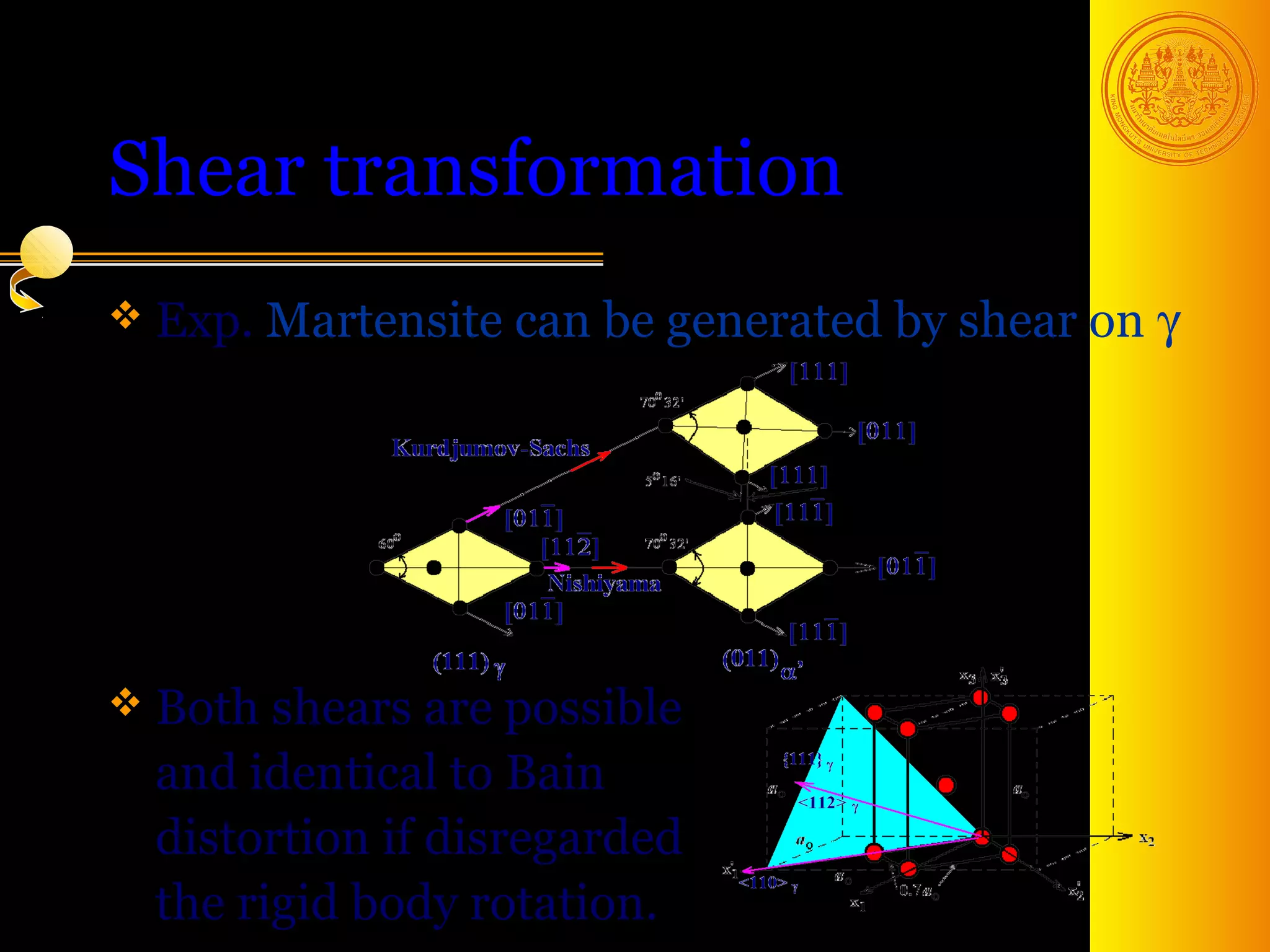

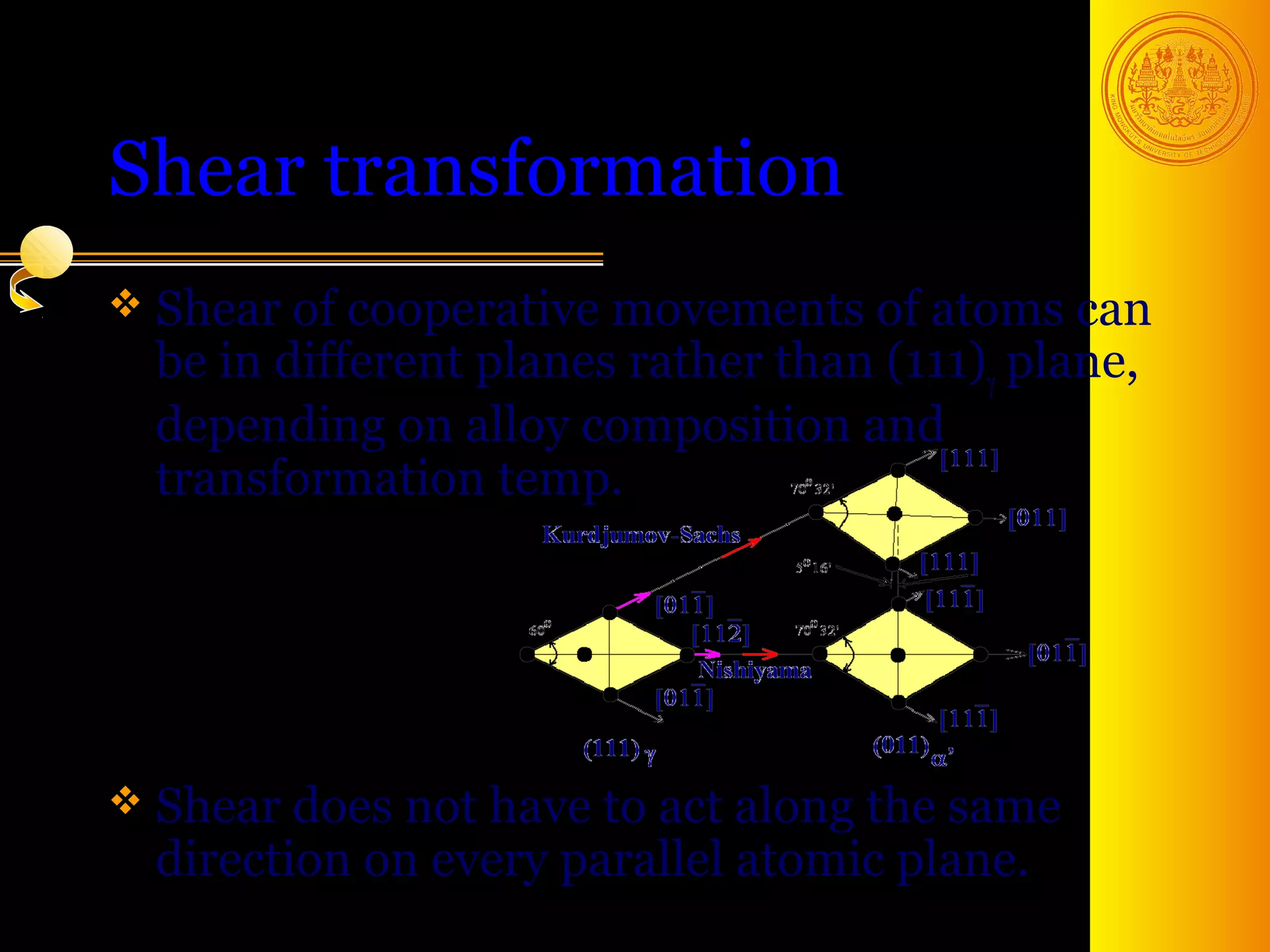

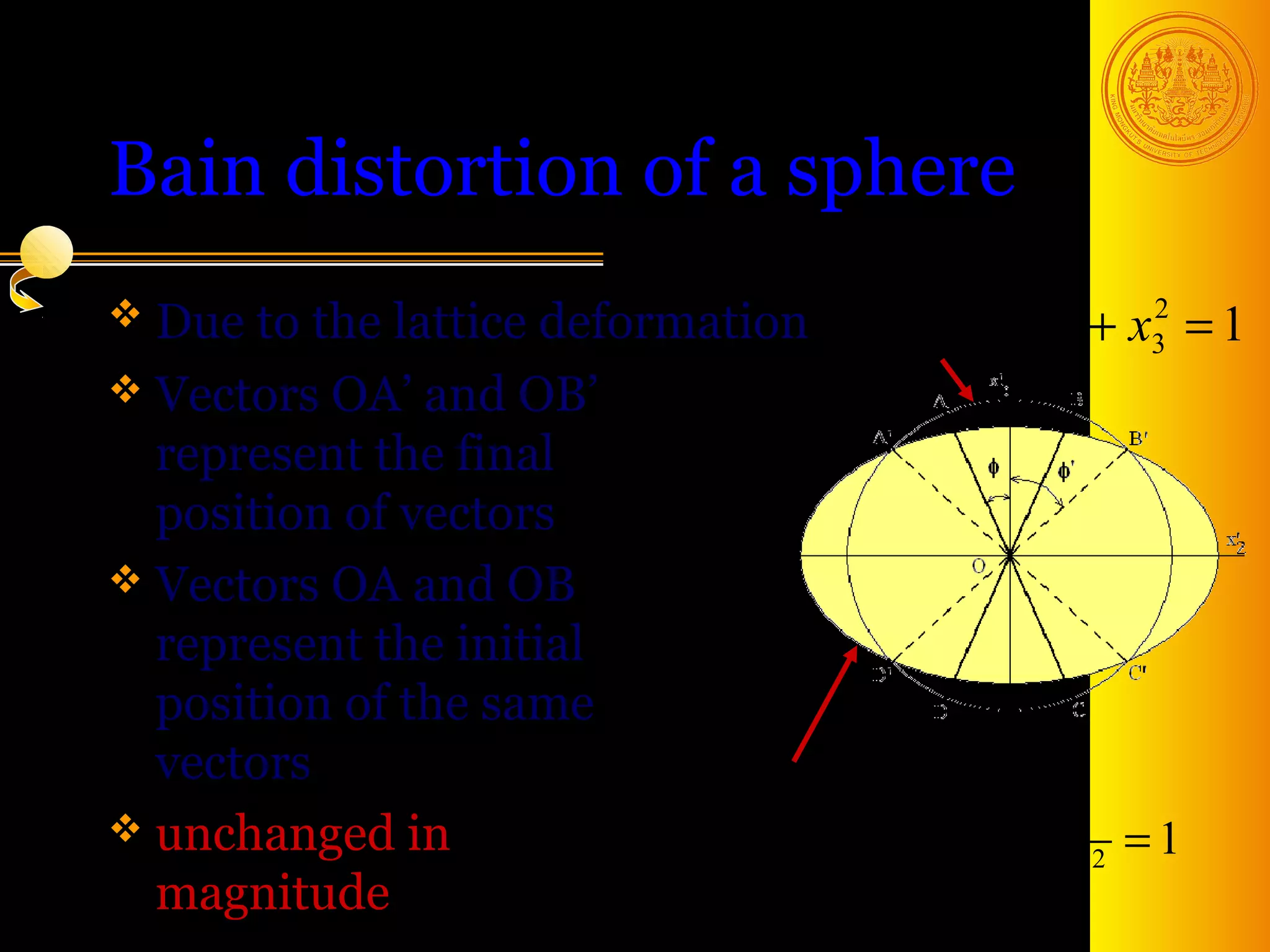

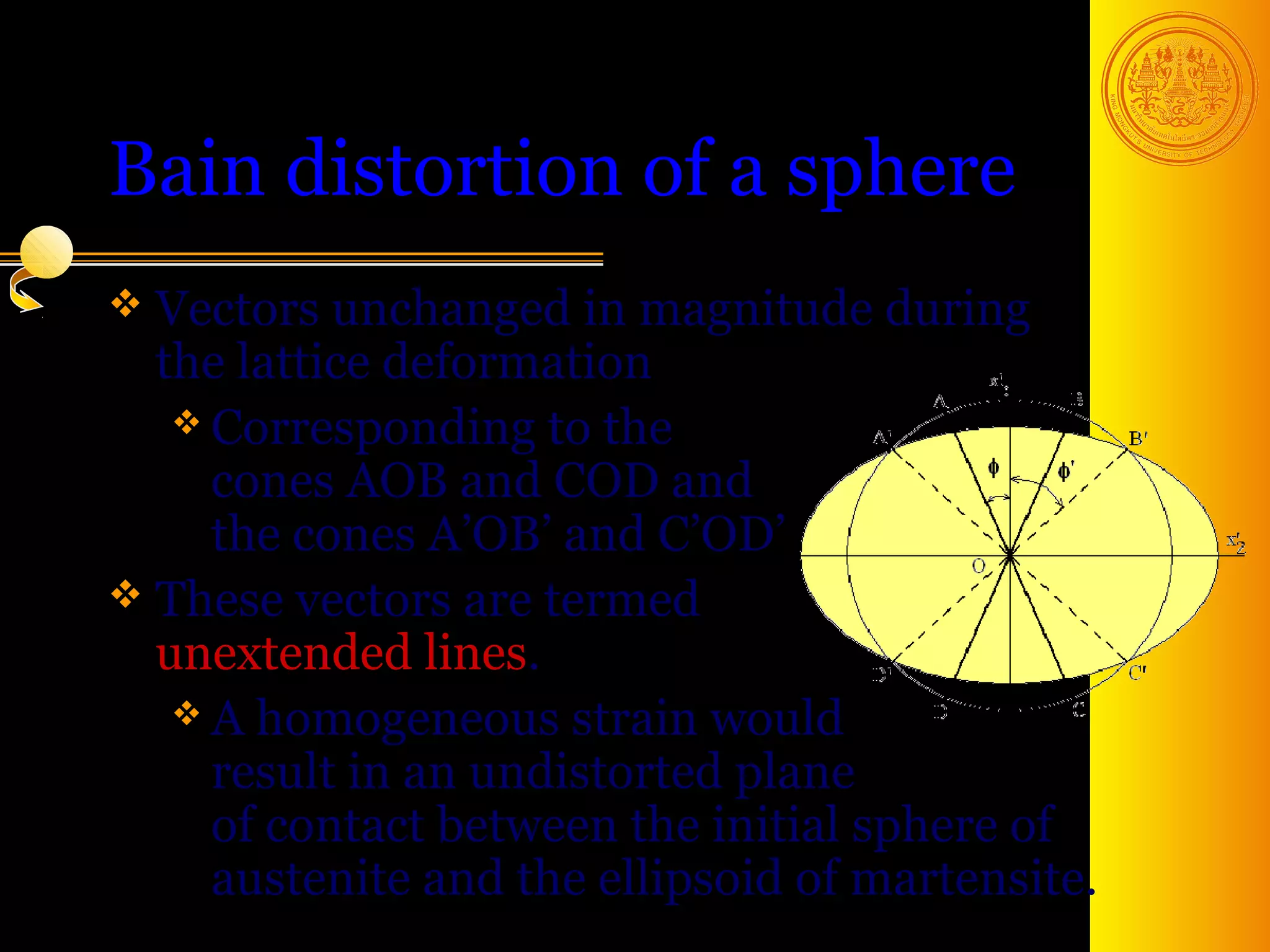

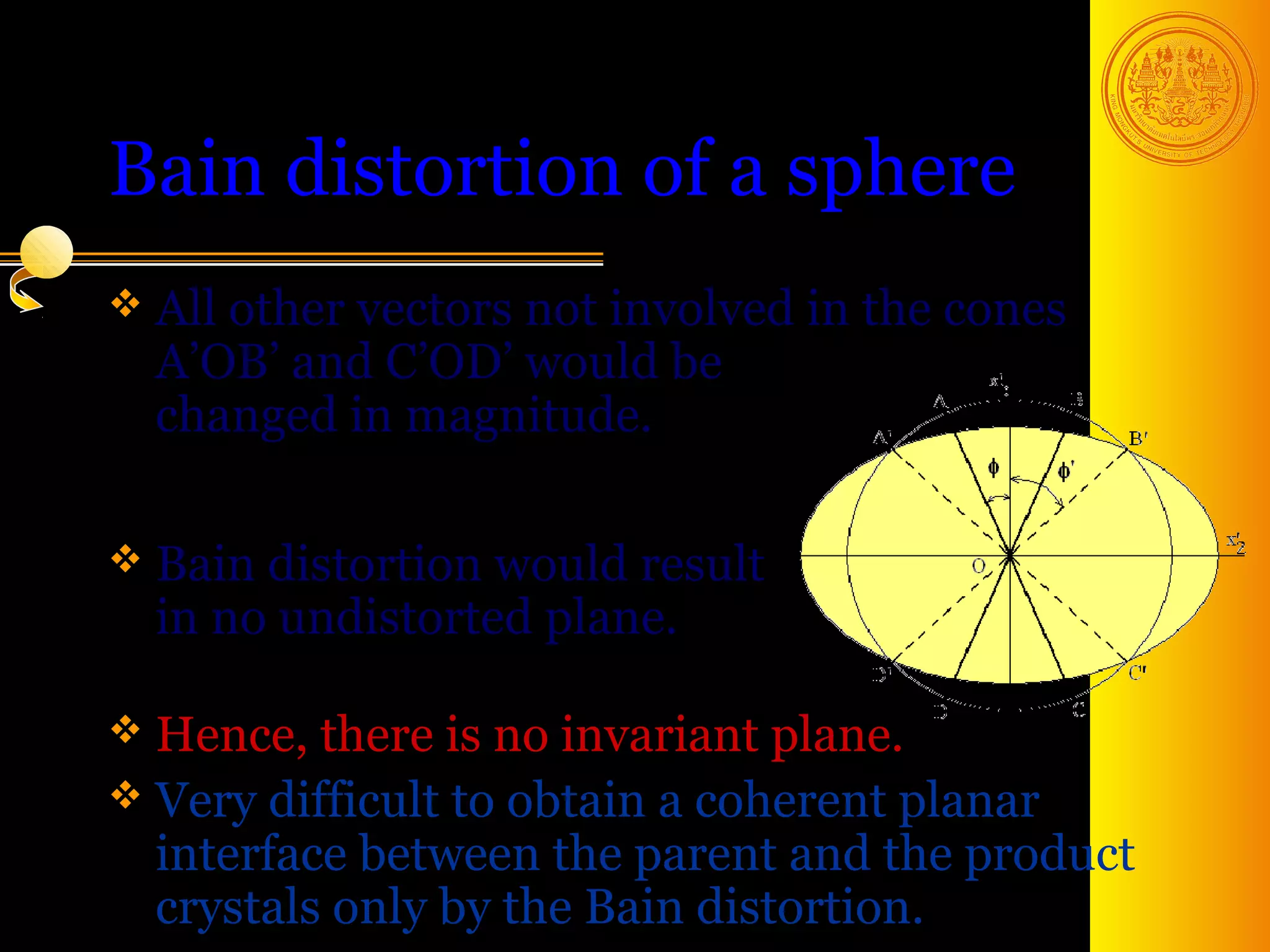

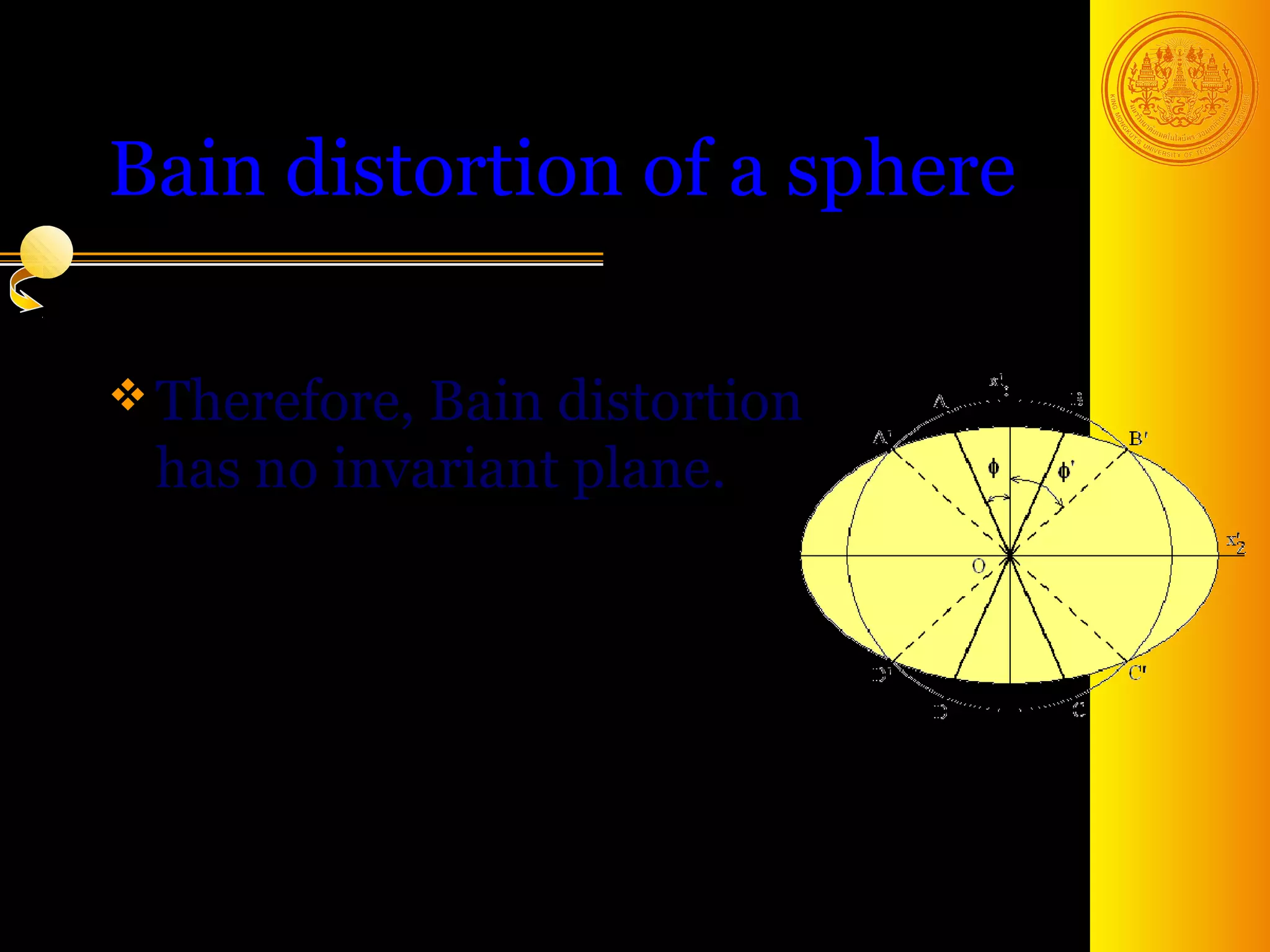

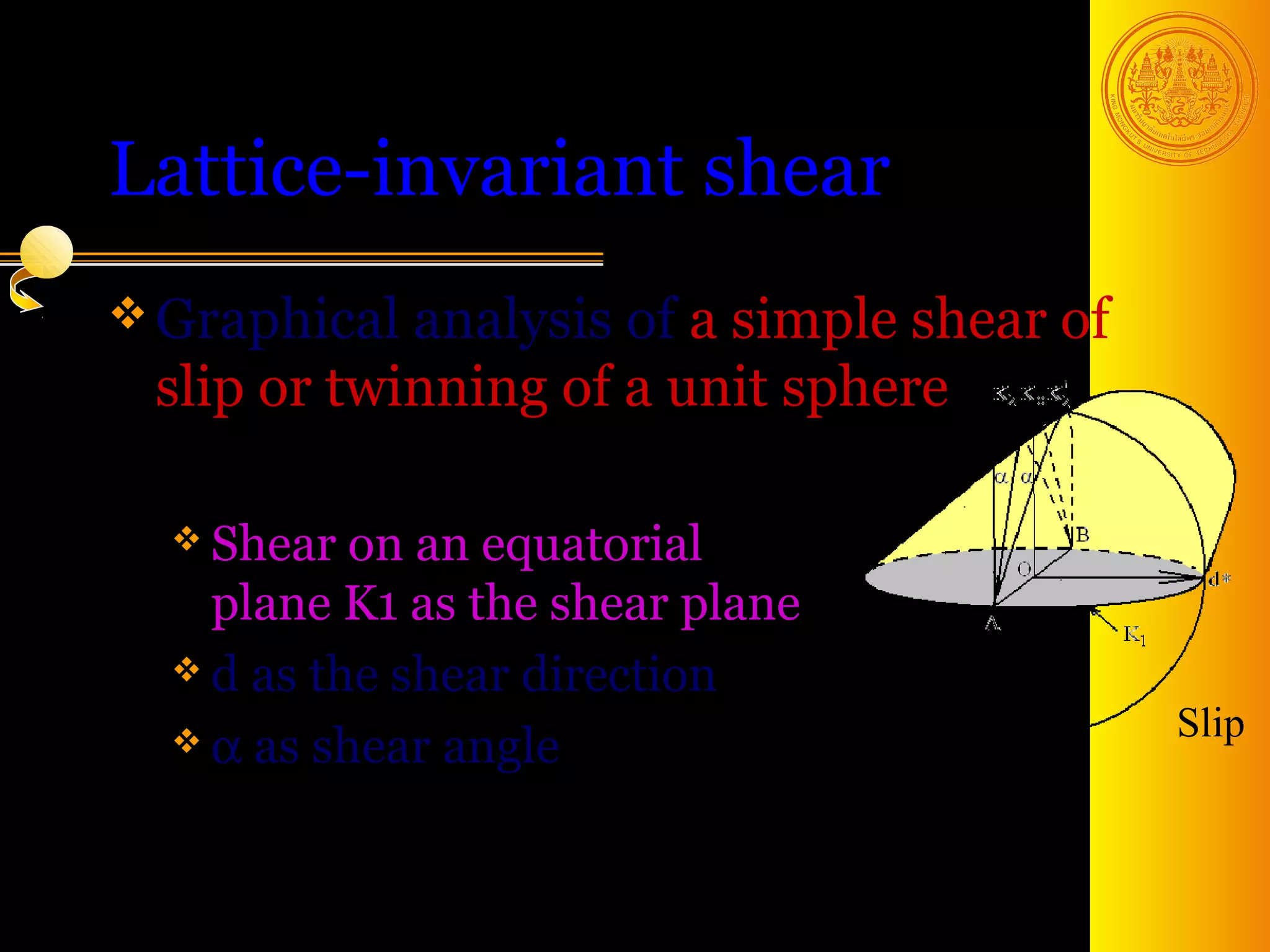

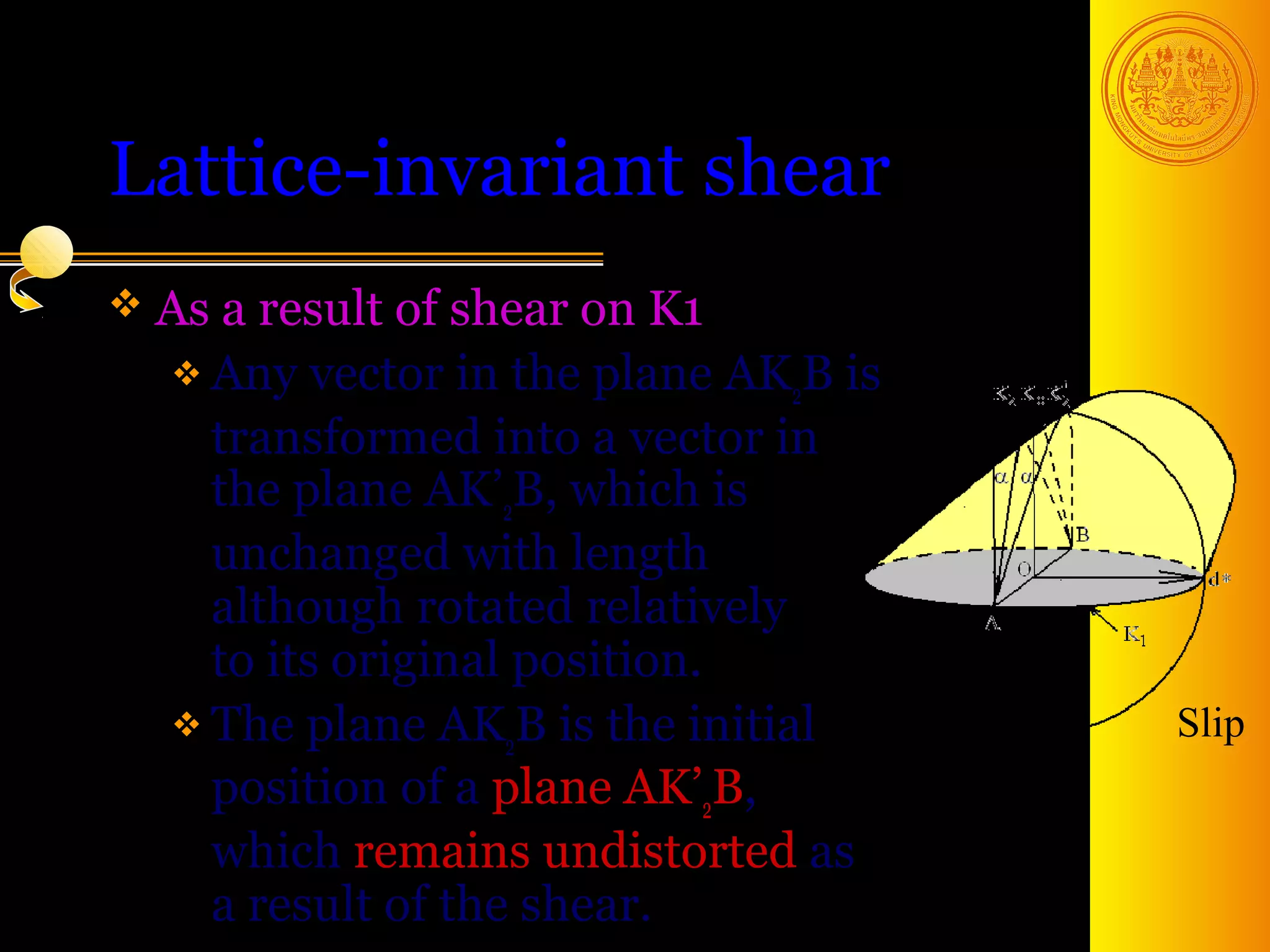

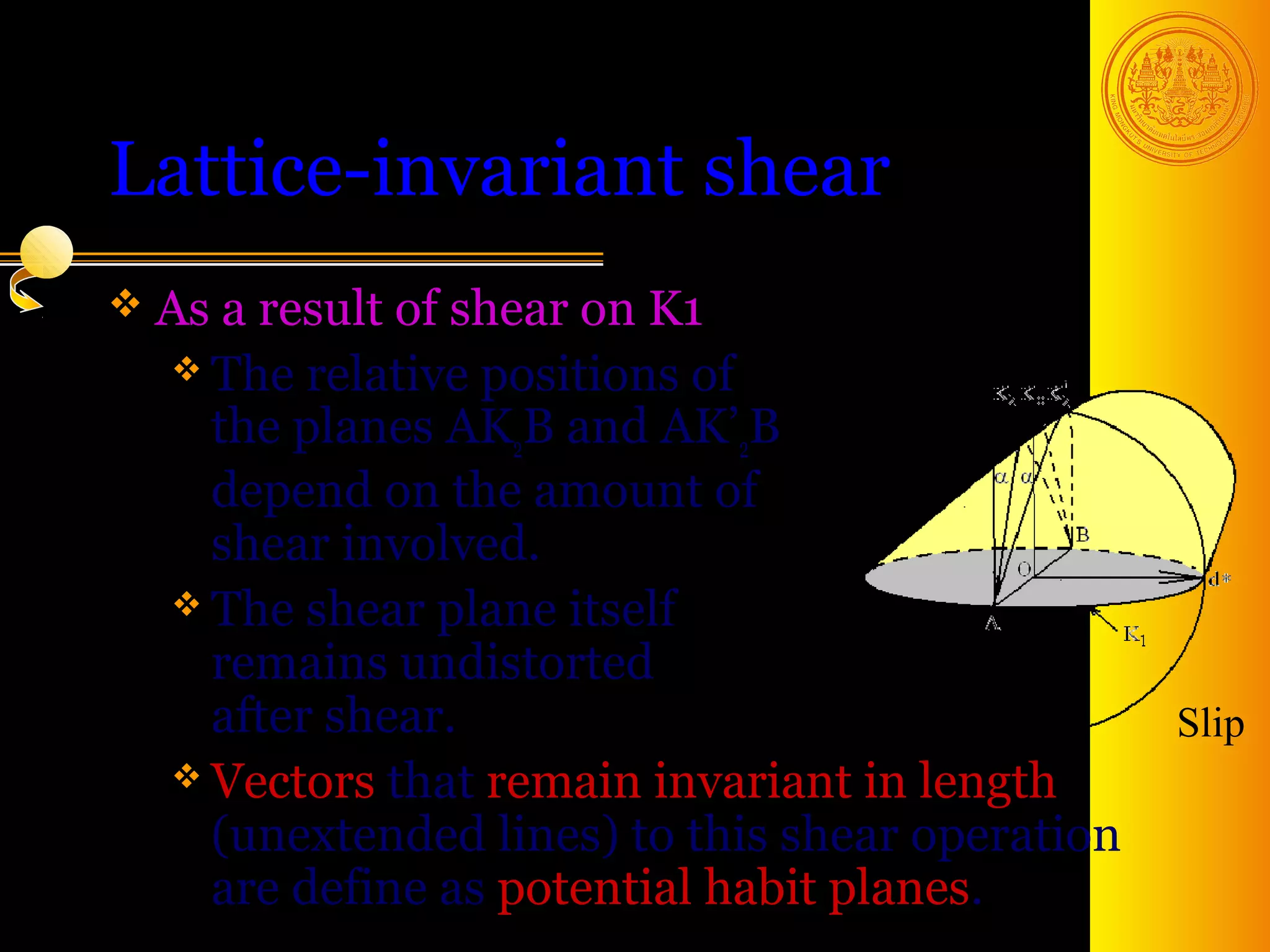

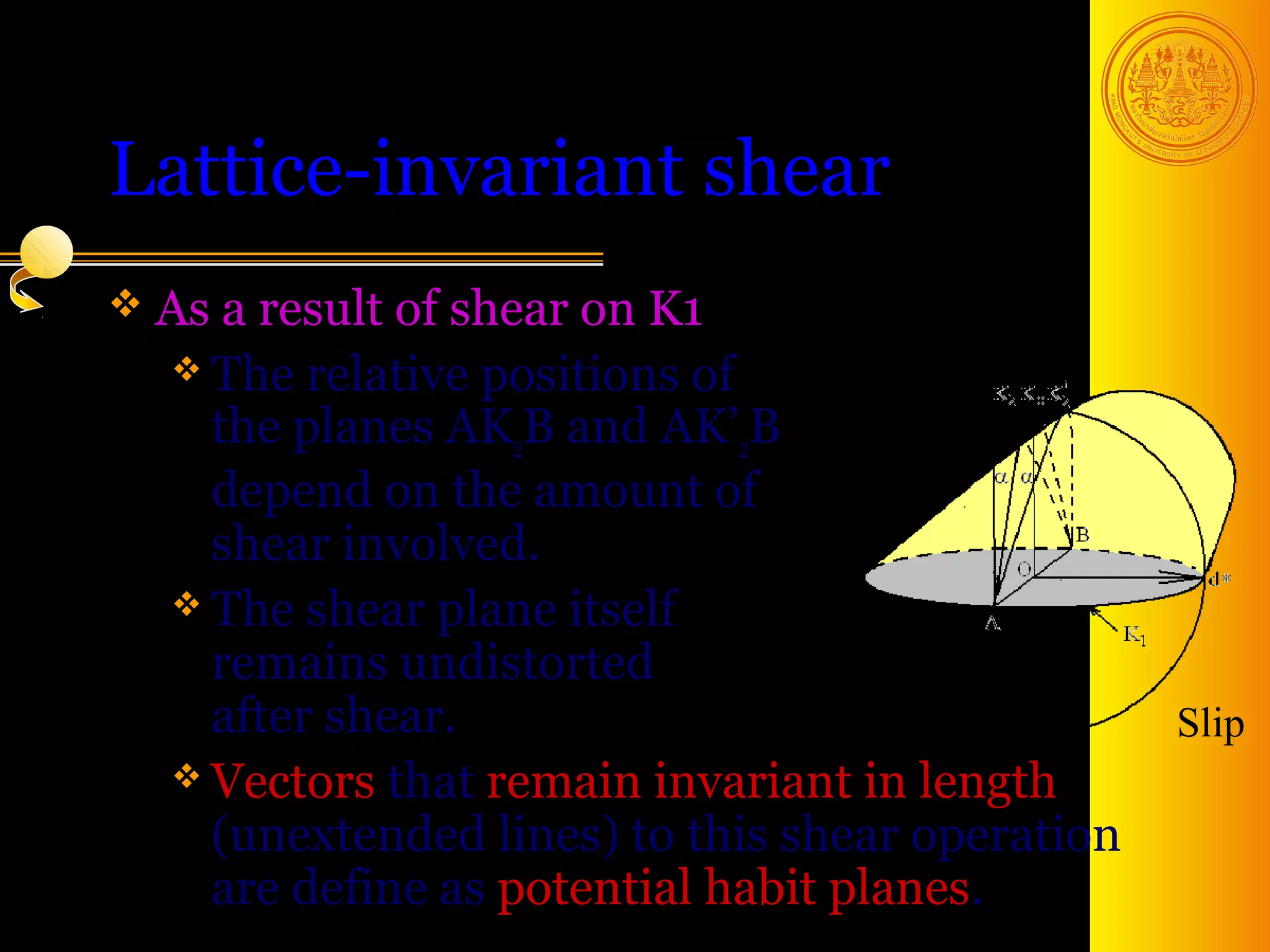

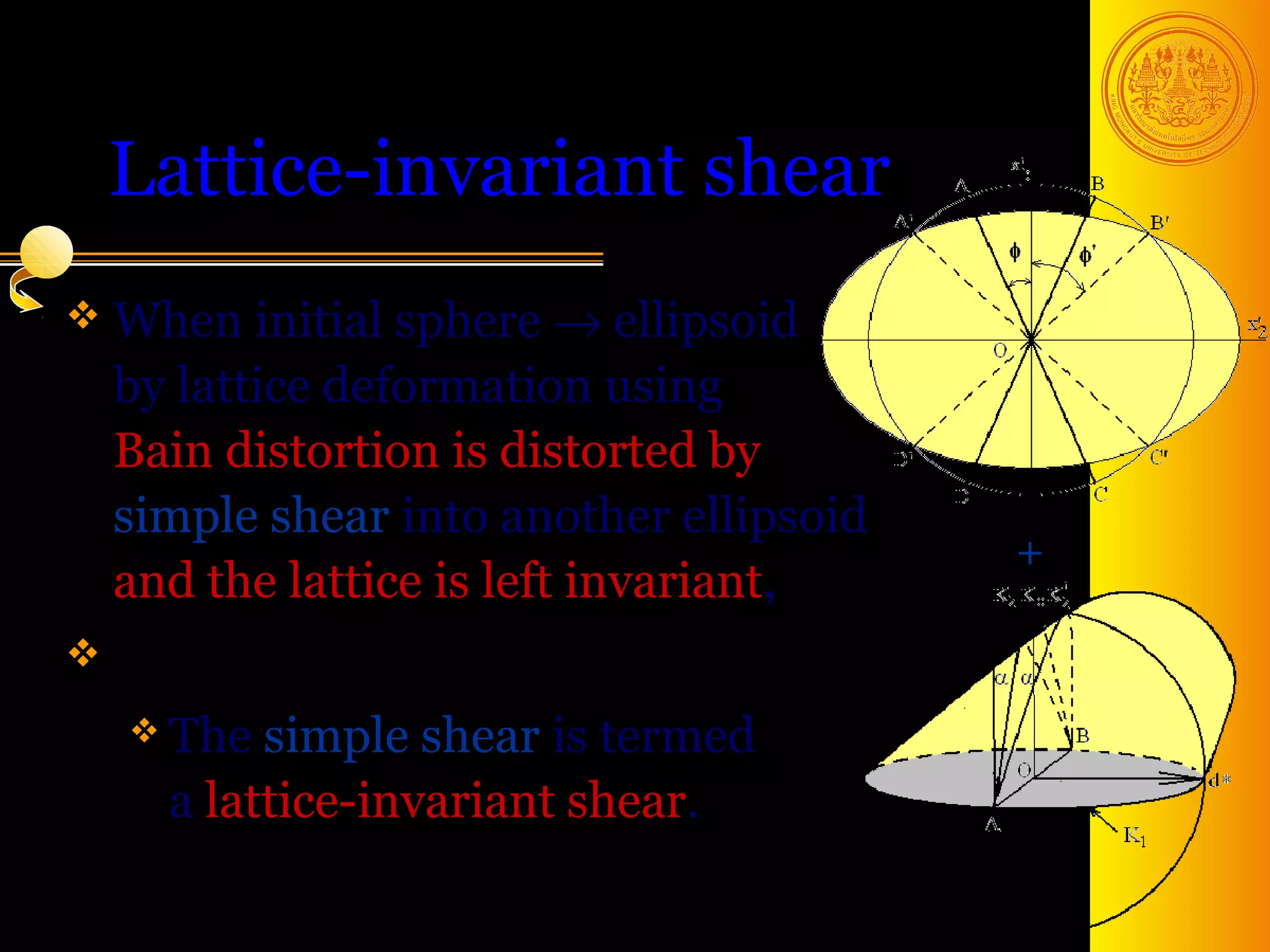

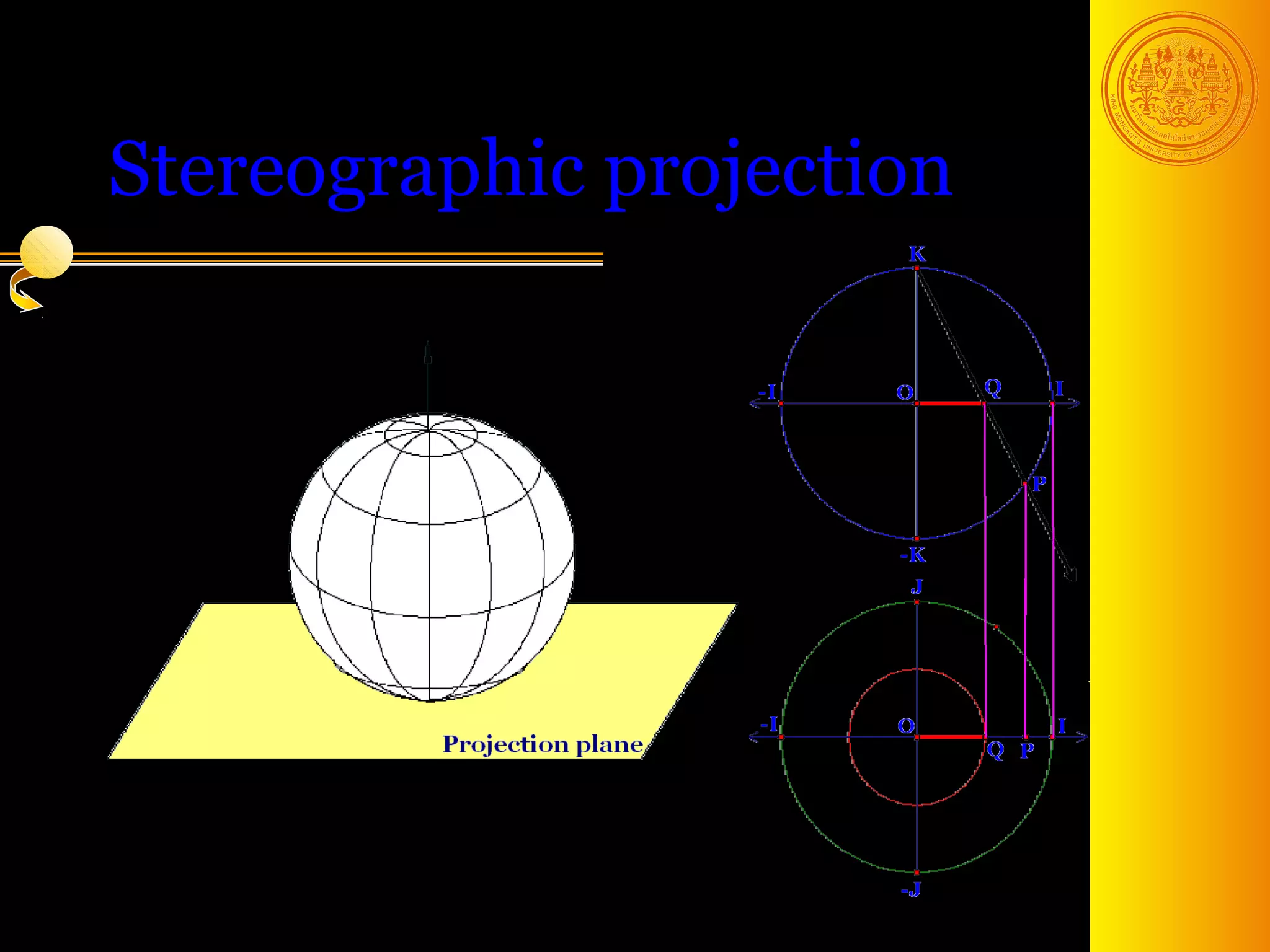

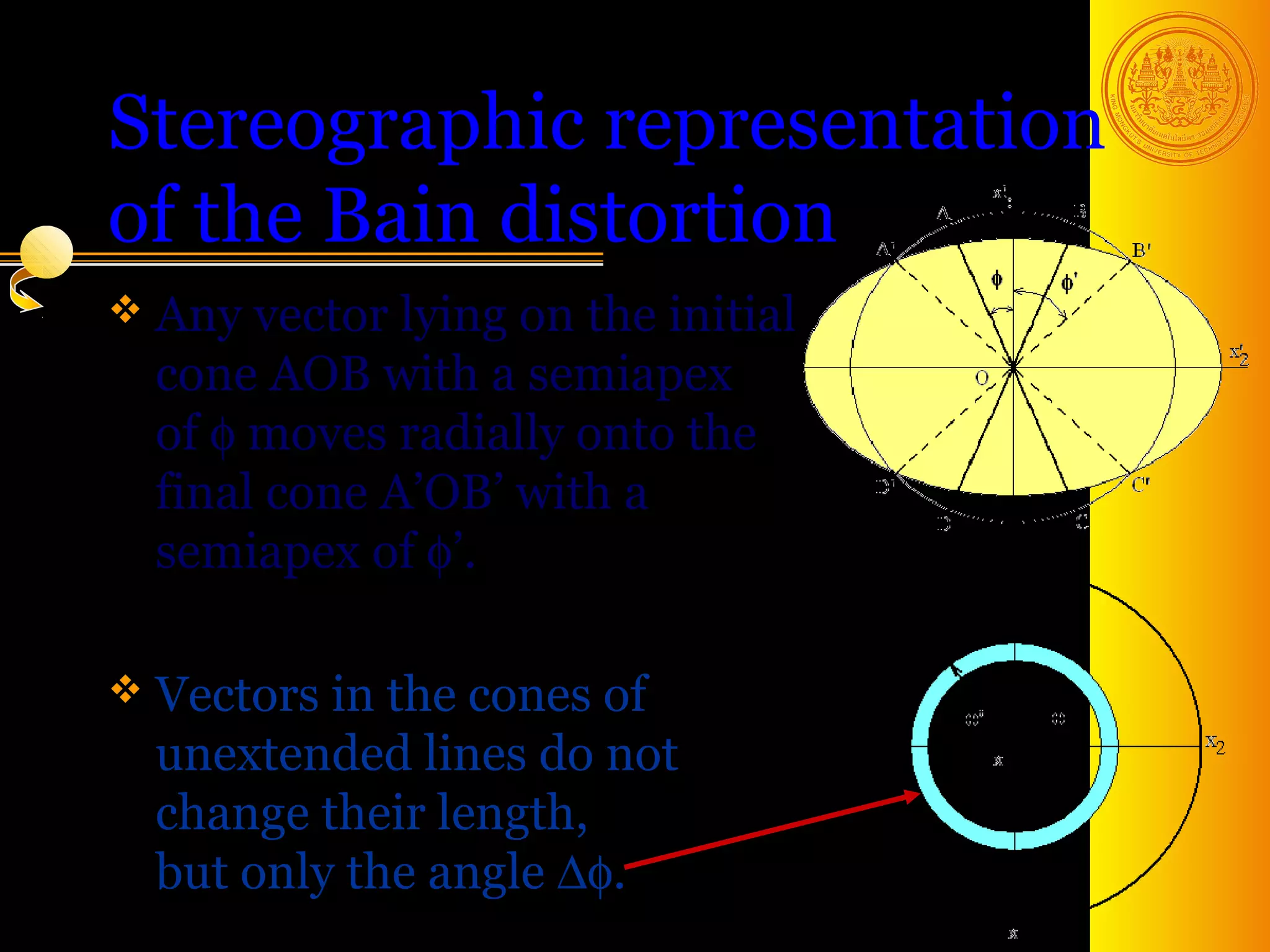

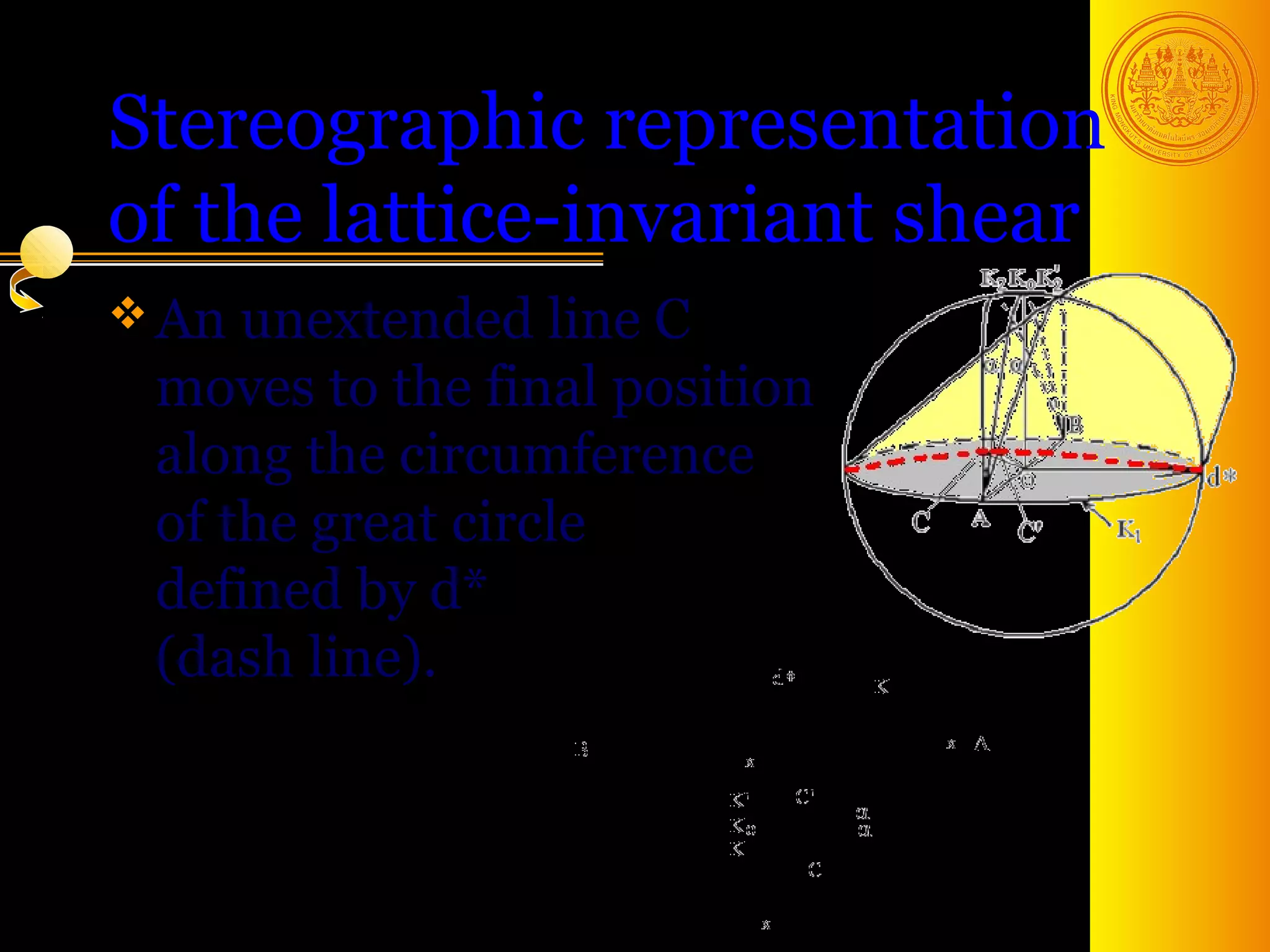

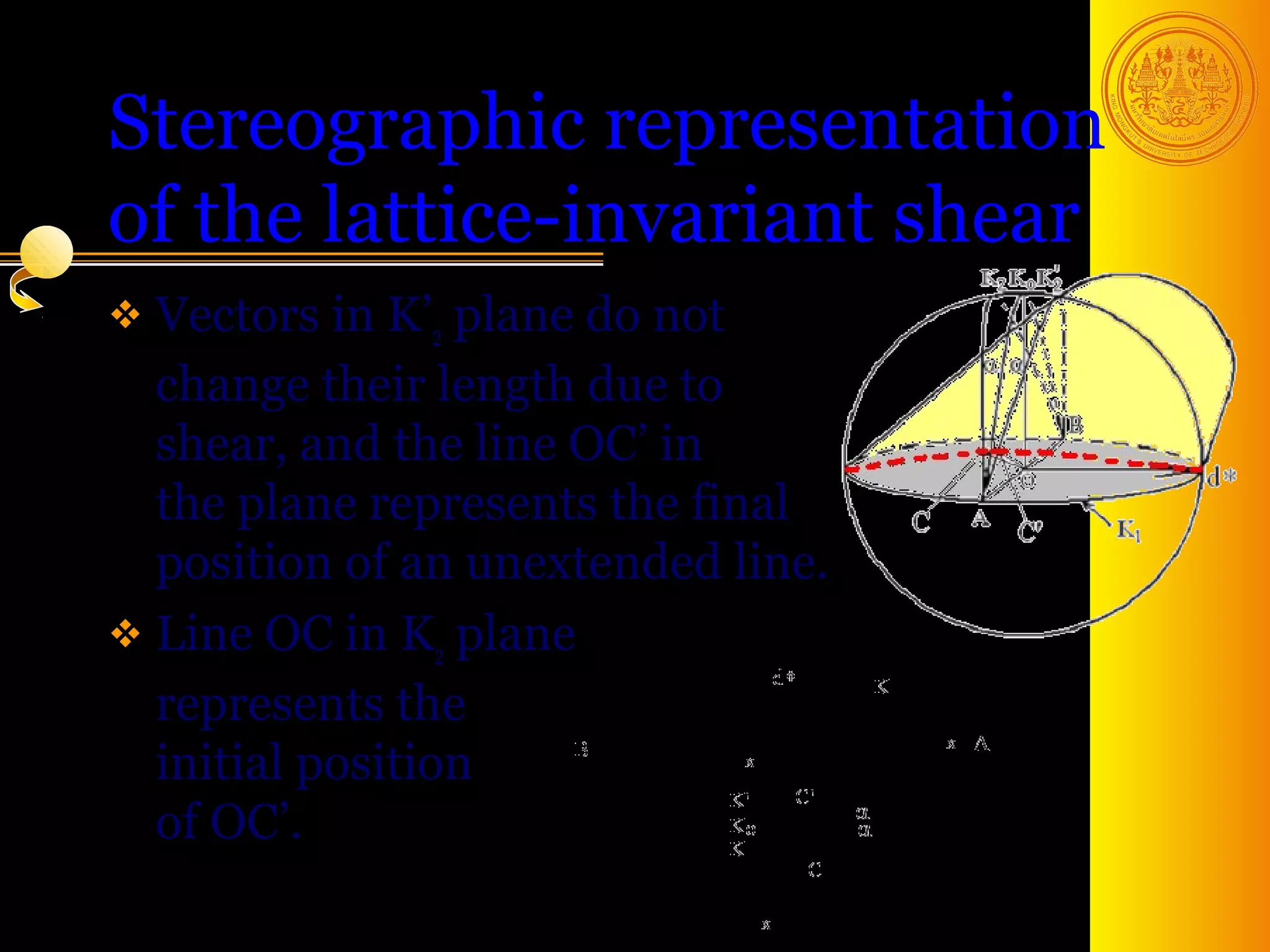

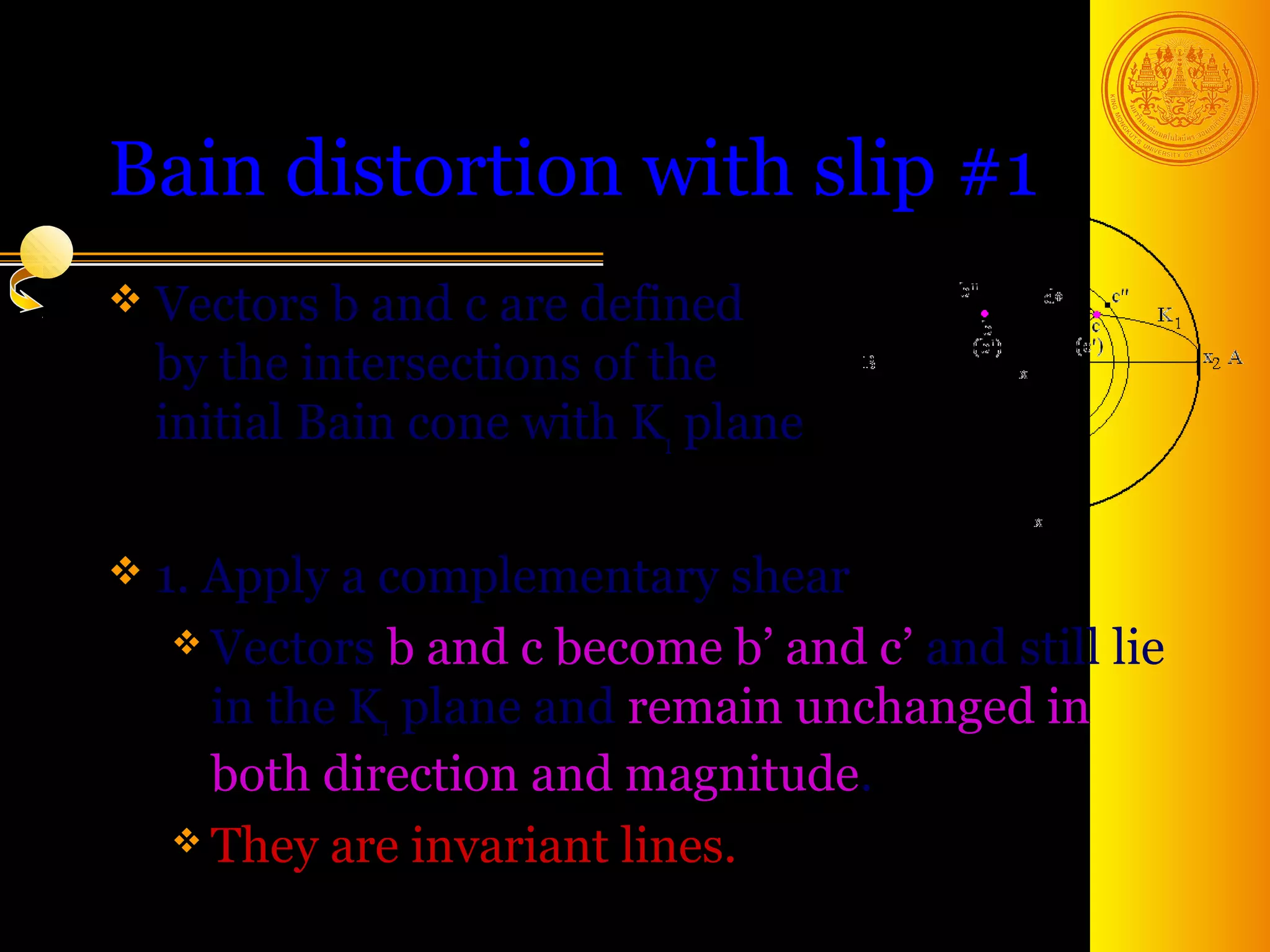

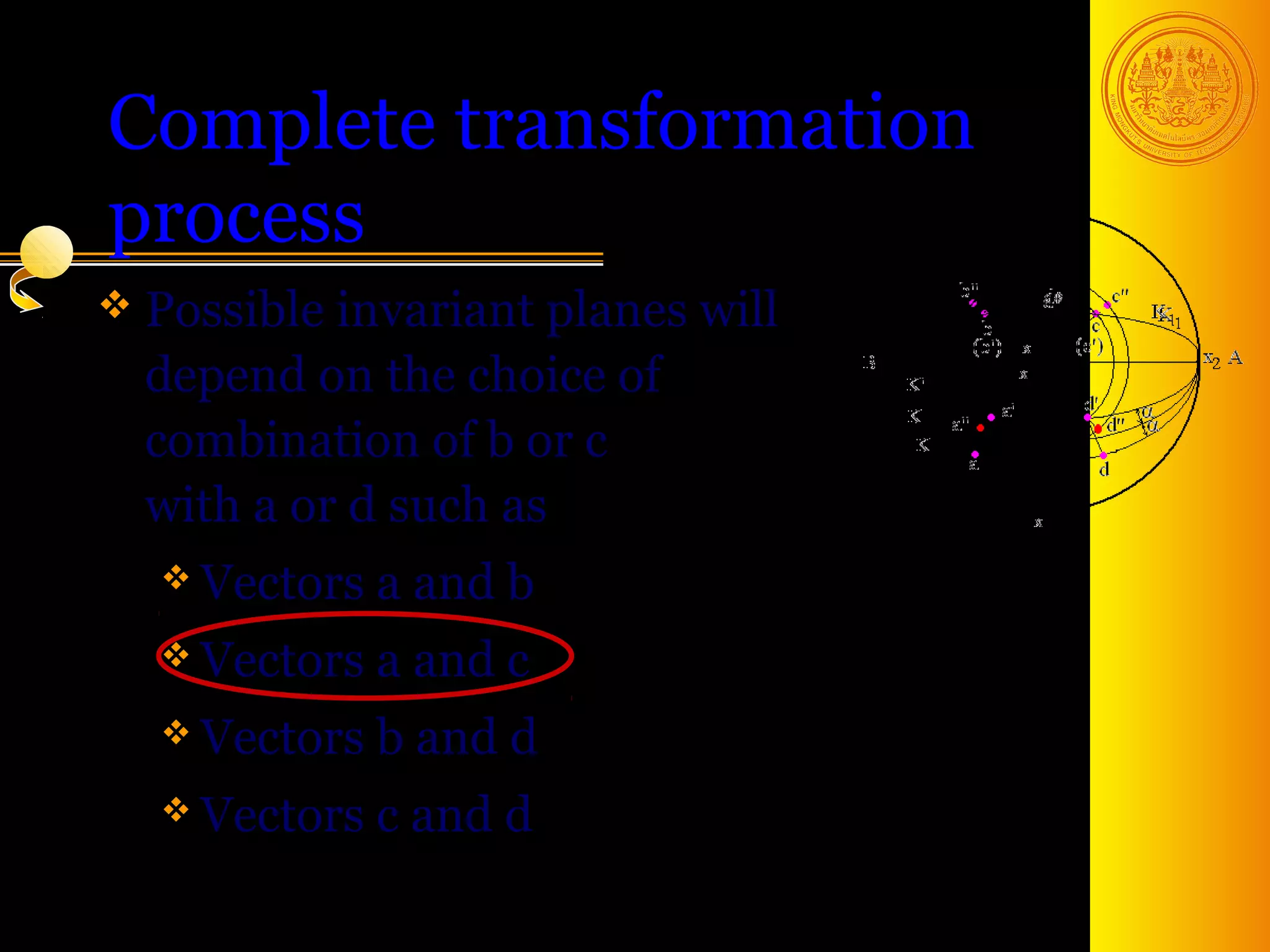

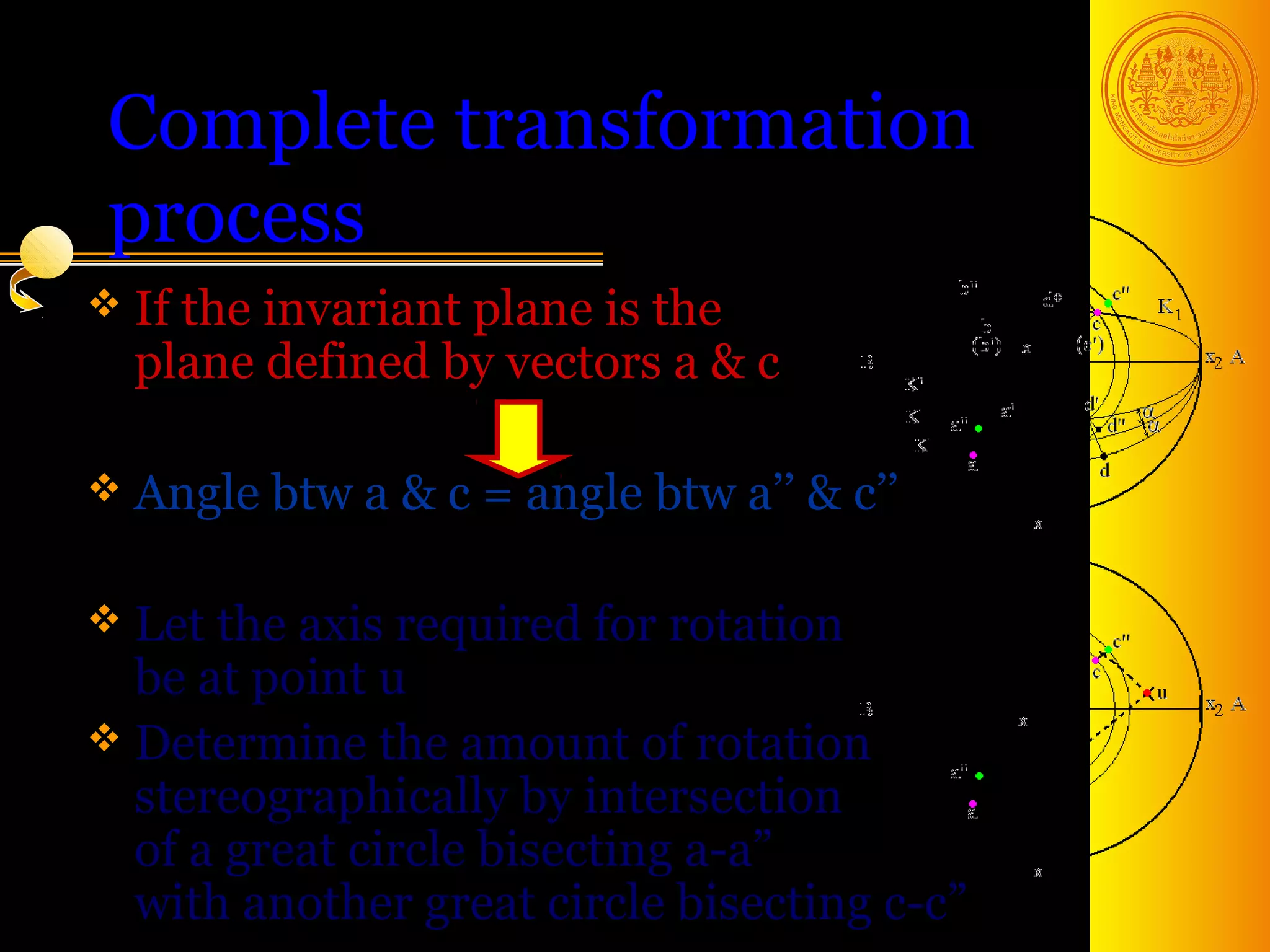

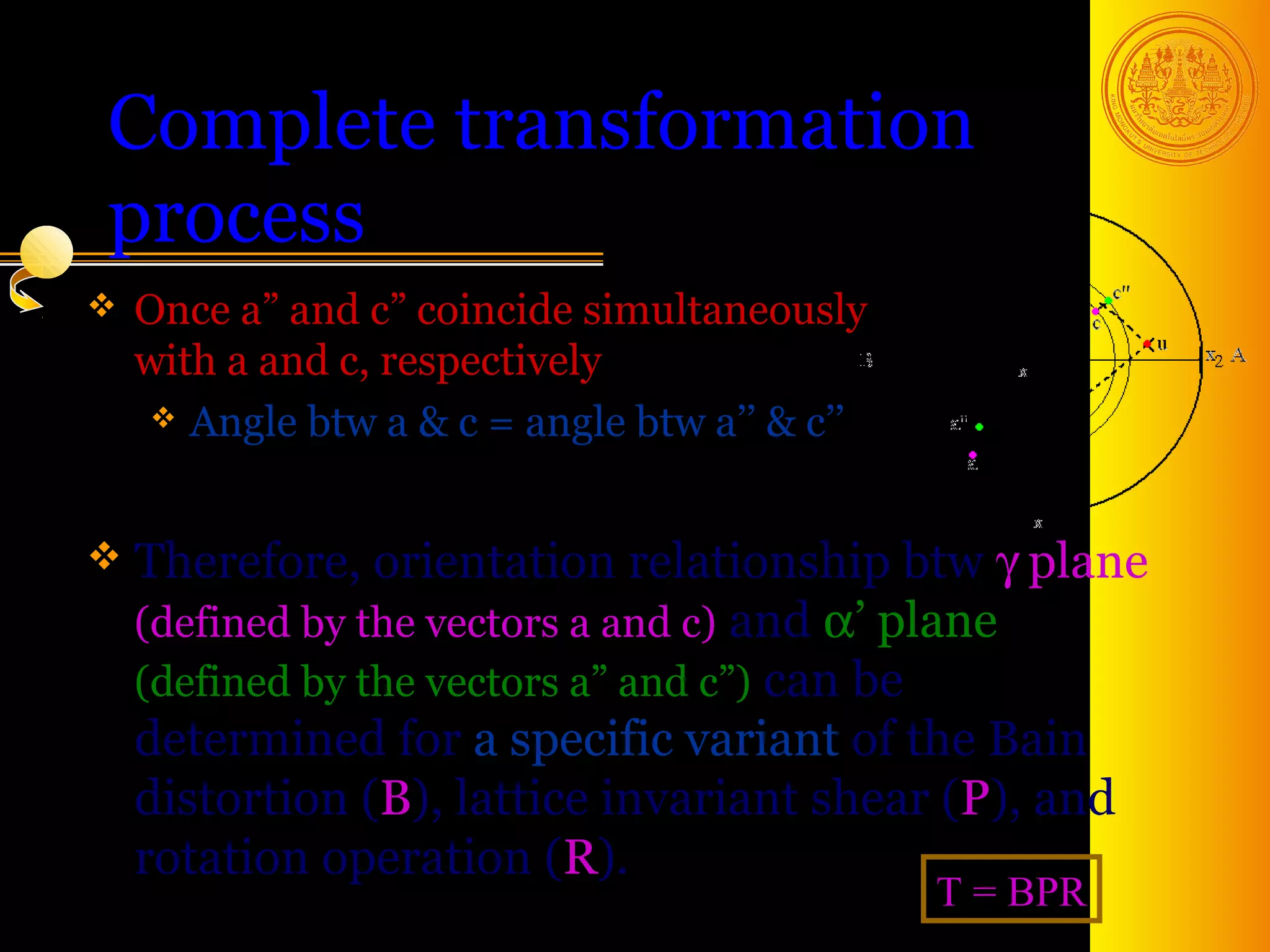

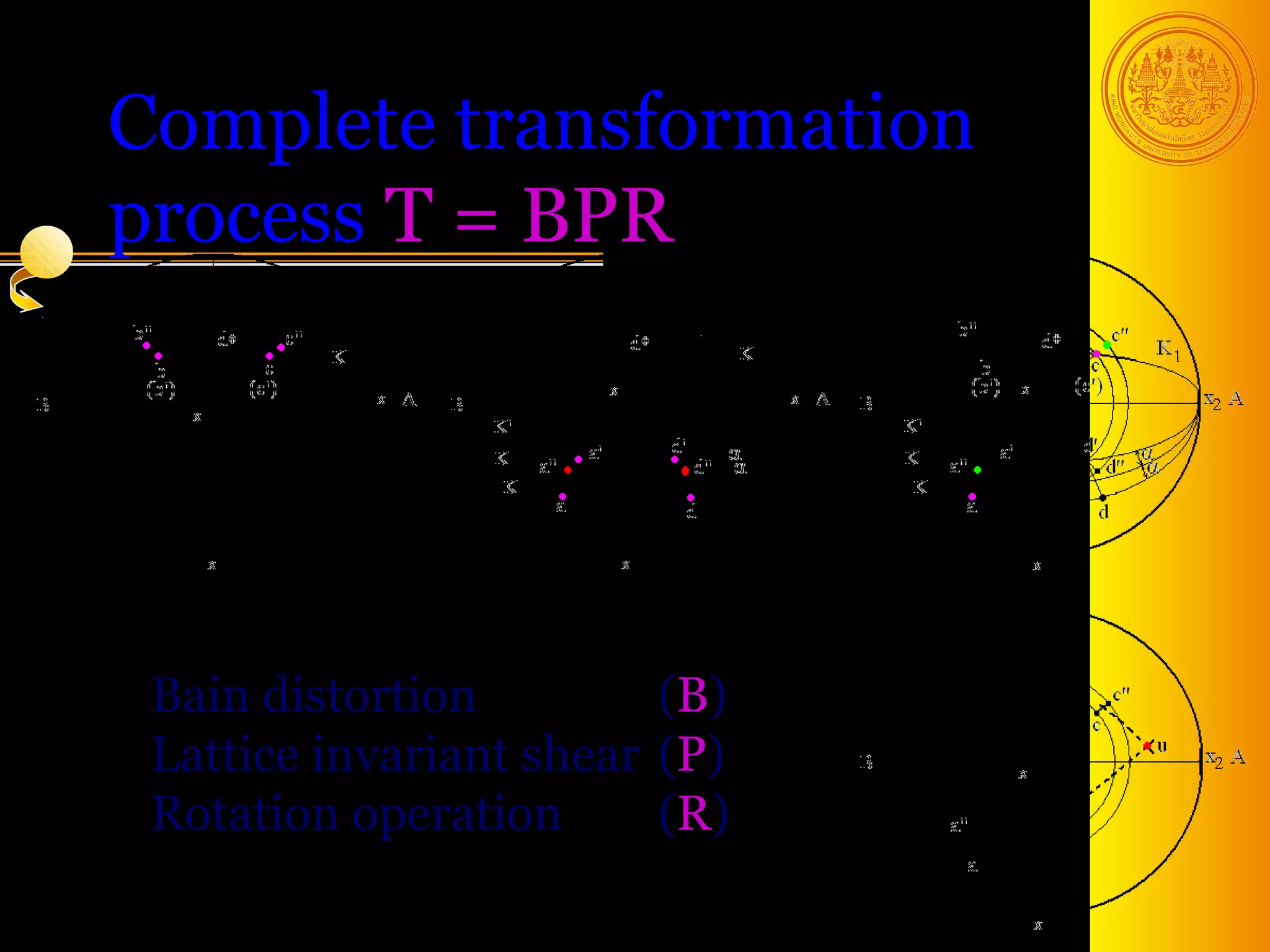

The document discusses phase transformations in solids, focusing on diffusionless martensitic transformations. It describes the mechanisms of martensite formation, including the Bain distortion, lattice-invariant shear, and rigid body rotation that constitute the complete transformation. It discusses nucleation and growth of martensite plates and laths, and how alloying elements and pressure can affect the martensitic transformation.

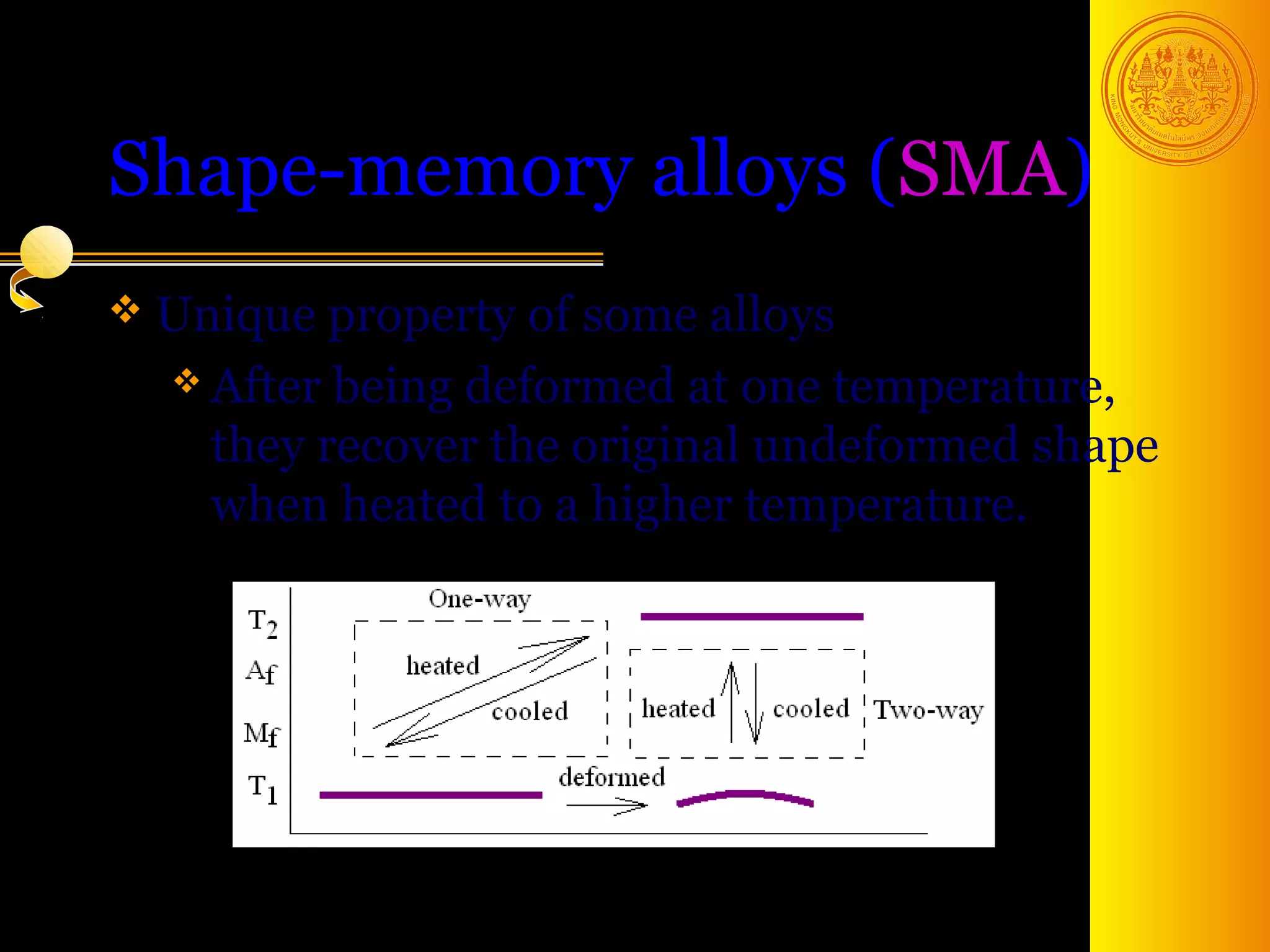

![Bain distortion with twinning

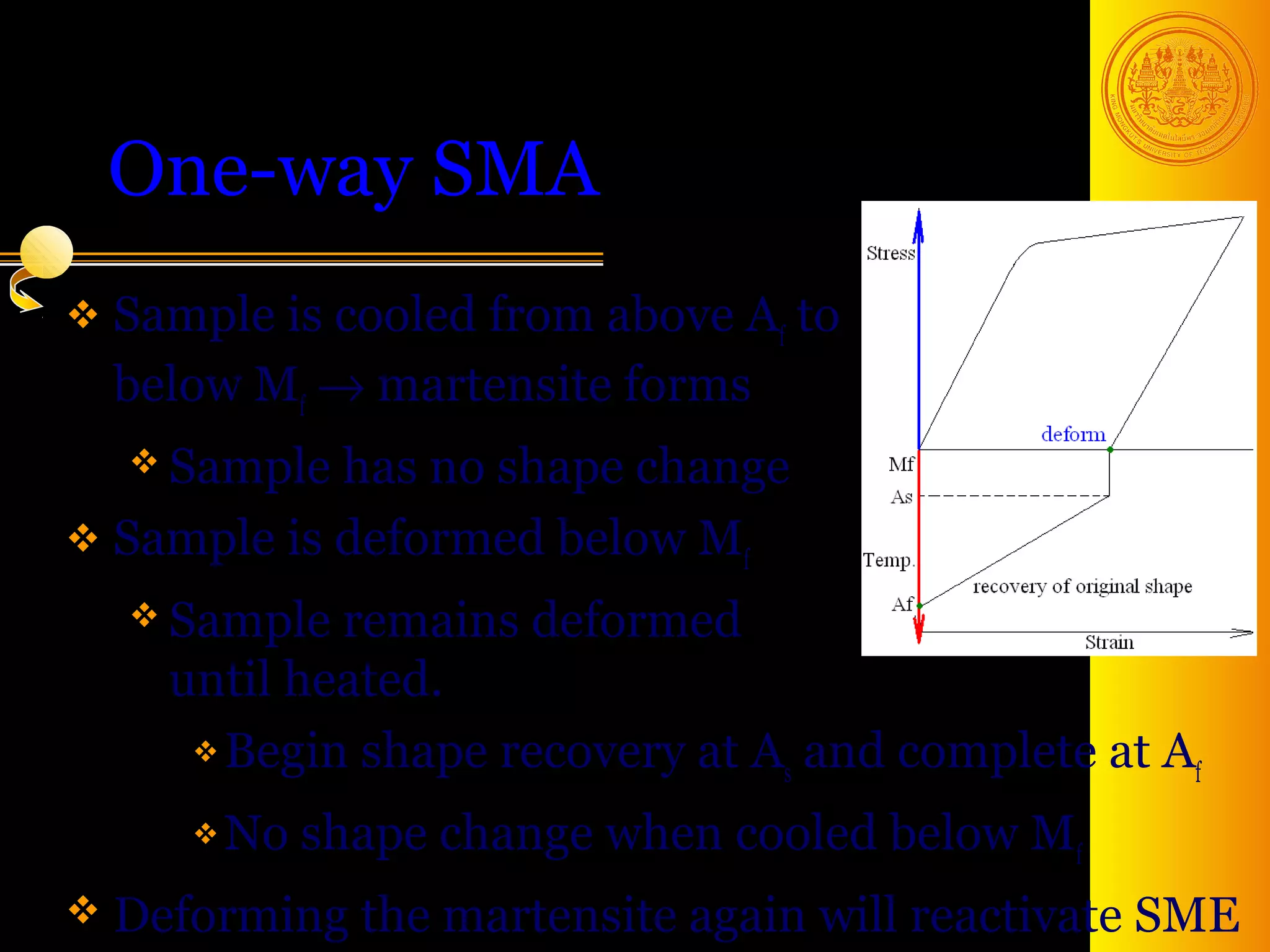

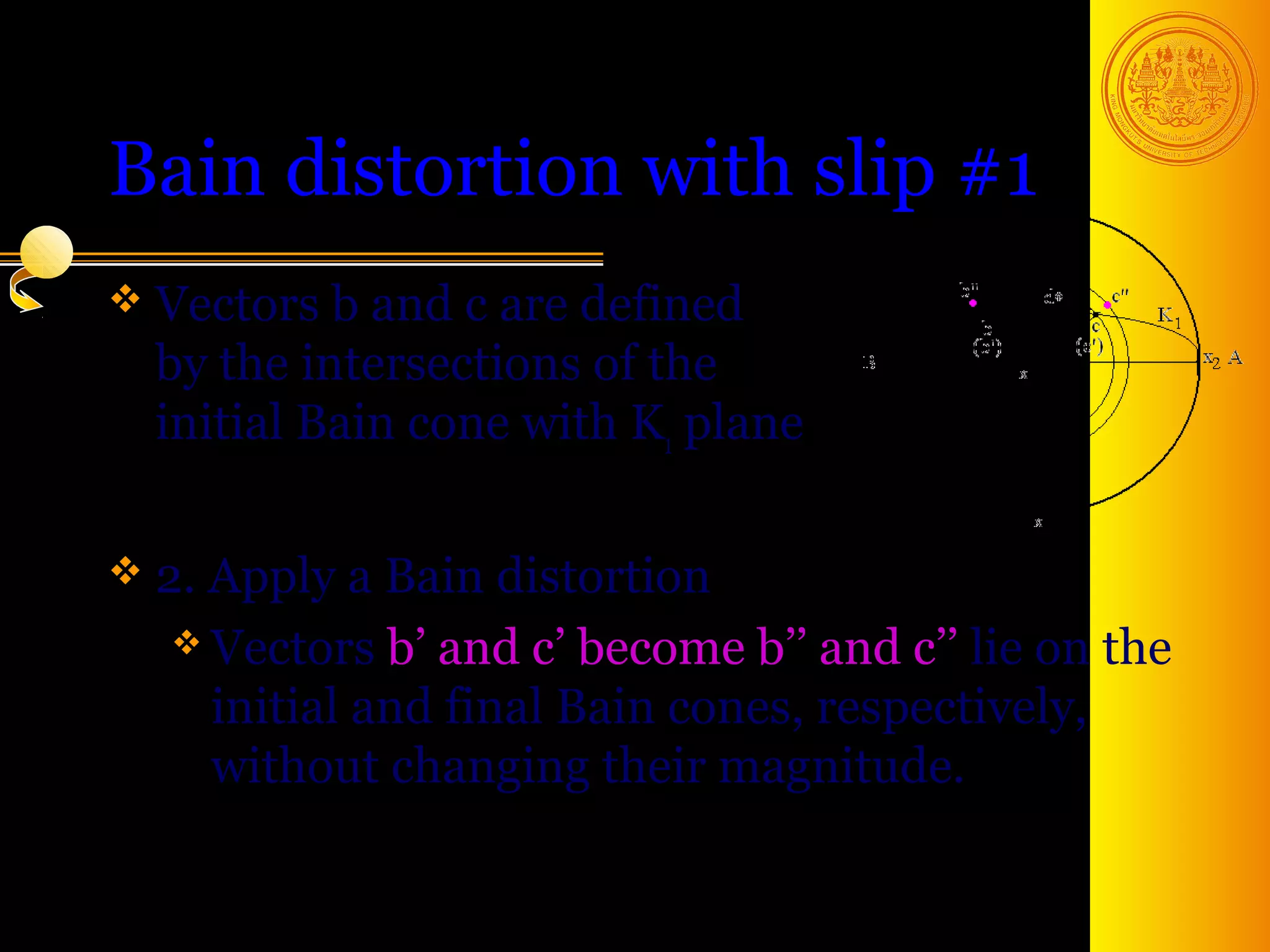

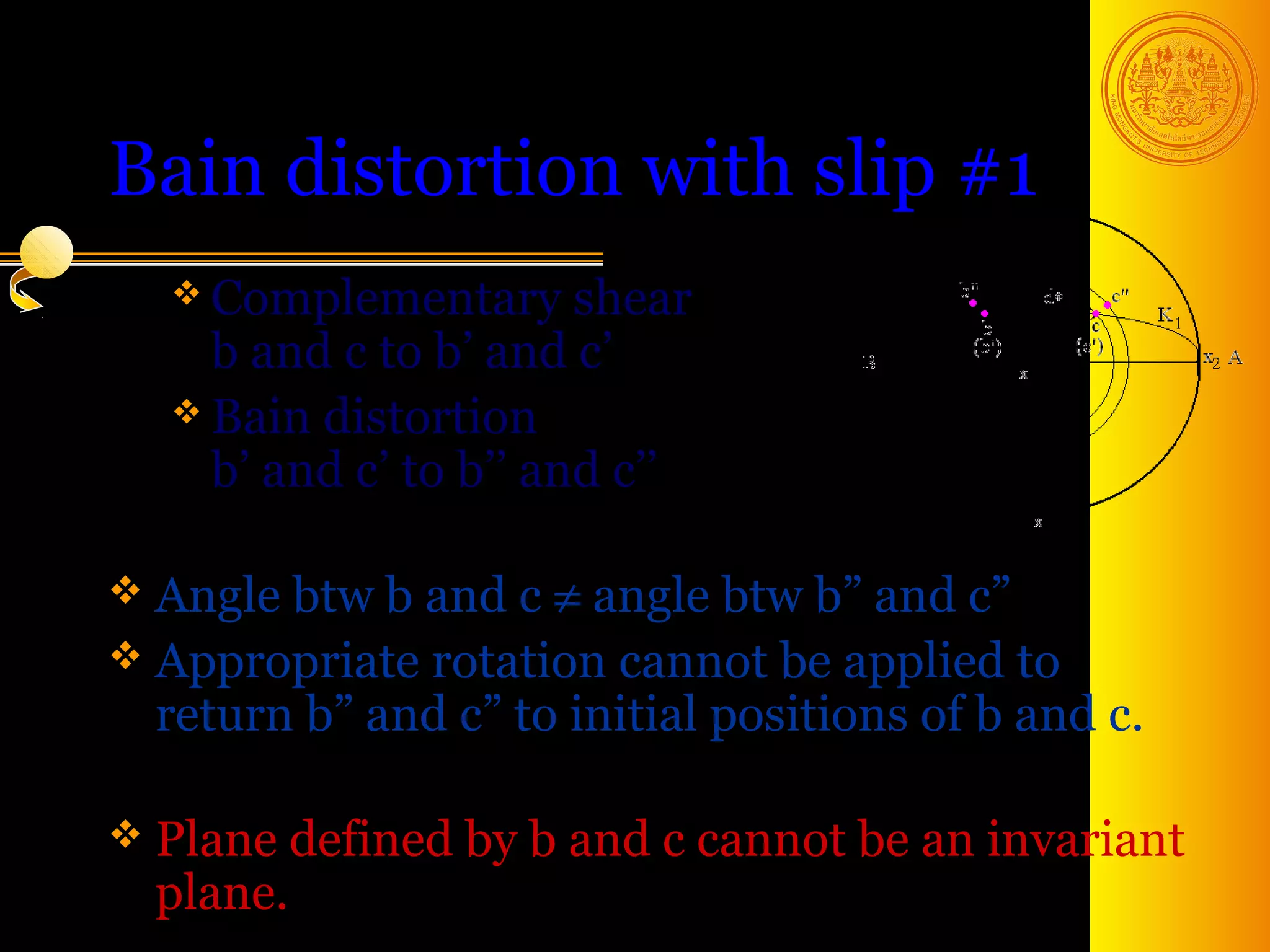

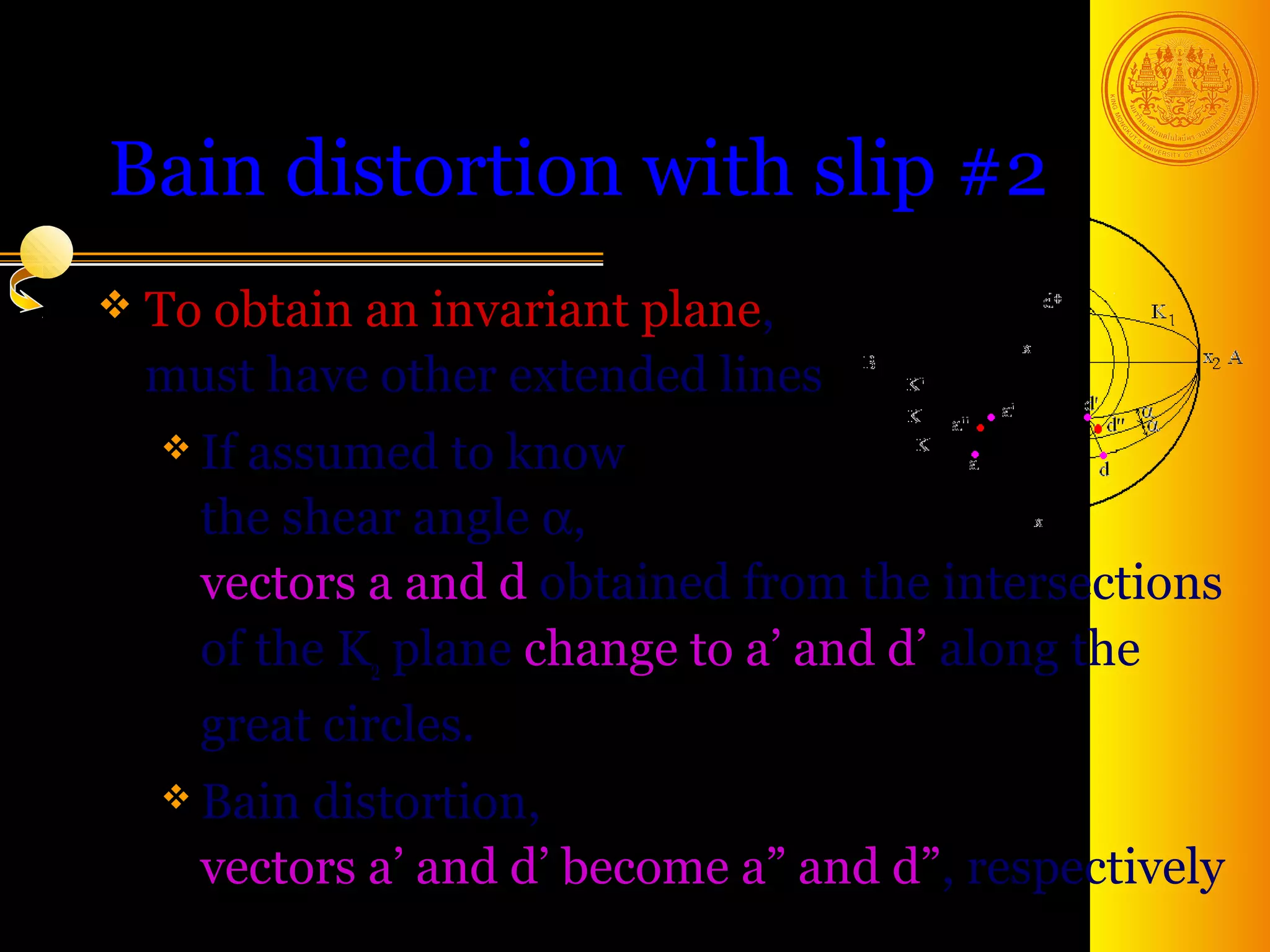

Twinned martensite can take place by having

alternate regions in the parent phase undergo

the lattice deformation along different

contraction axes, which are initially at right

angles to each other.

In the first region, contraction occurs along

the x3 [ 001] f axis.

In the adjacent region, contraction direction

can be either x1 [100] f or x2 [ 010] f axis.

Two rigid body rotations are also involved in

the twinning analysis. 36](https://image.slidesharecdn.com/mt610phasetransformationsinsolidsiv-130211133504-phpapp02/75/Mt-610-phasetransformationsinsolids_iv-36-2048.jpg)

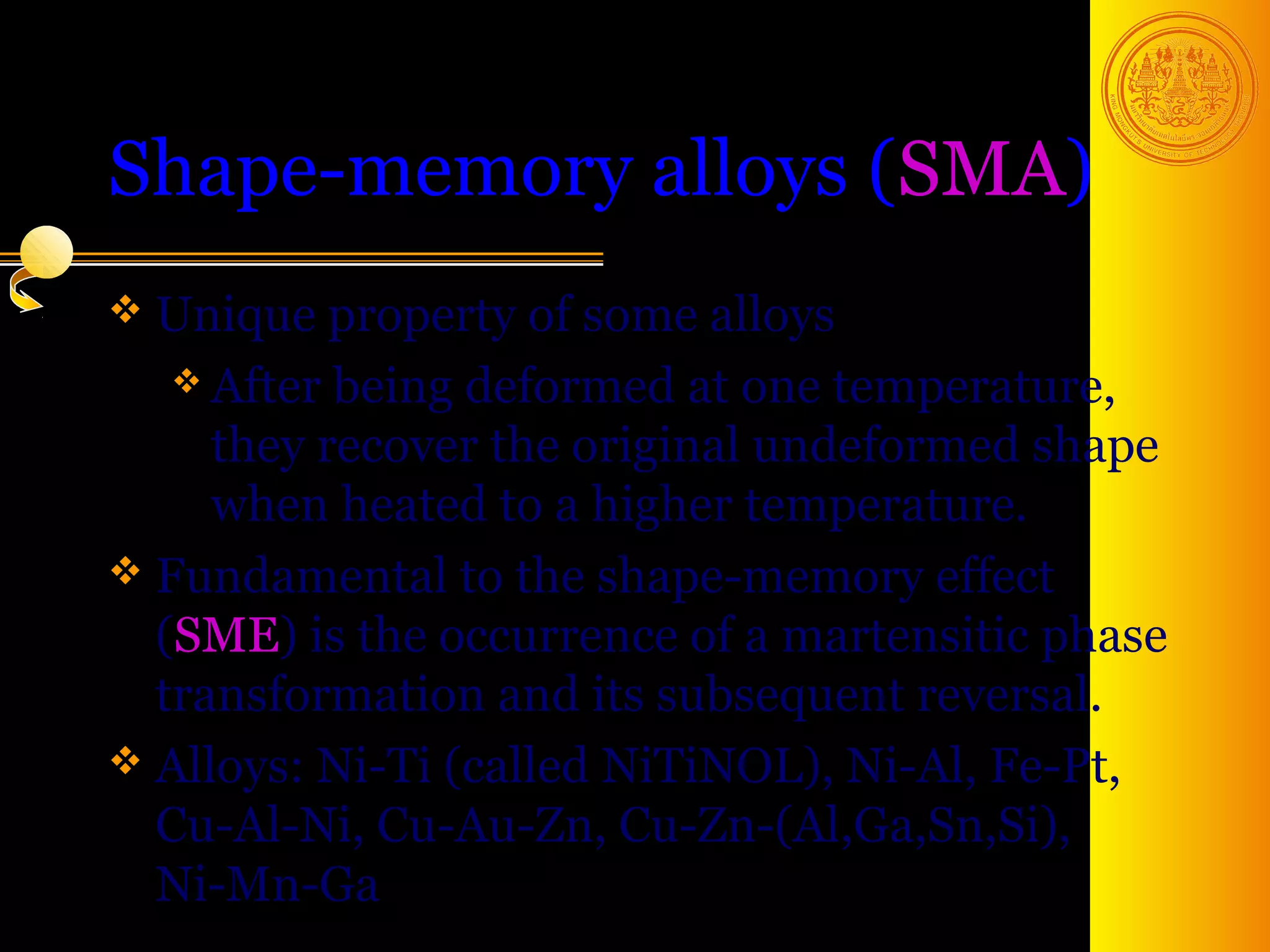

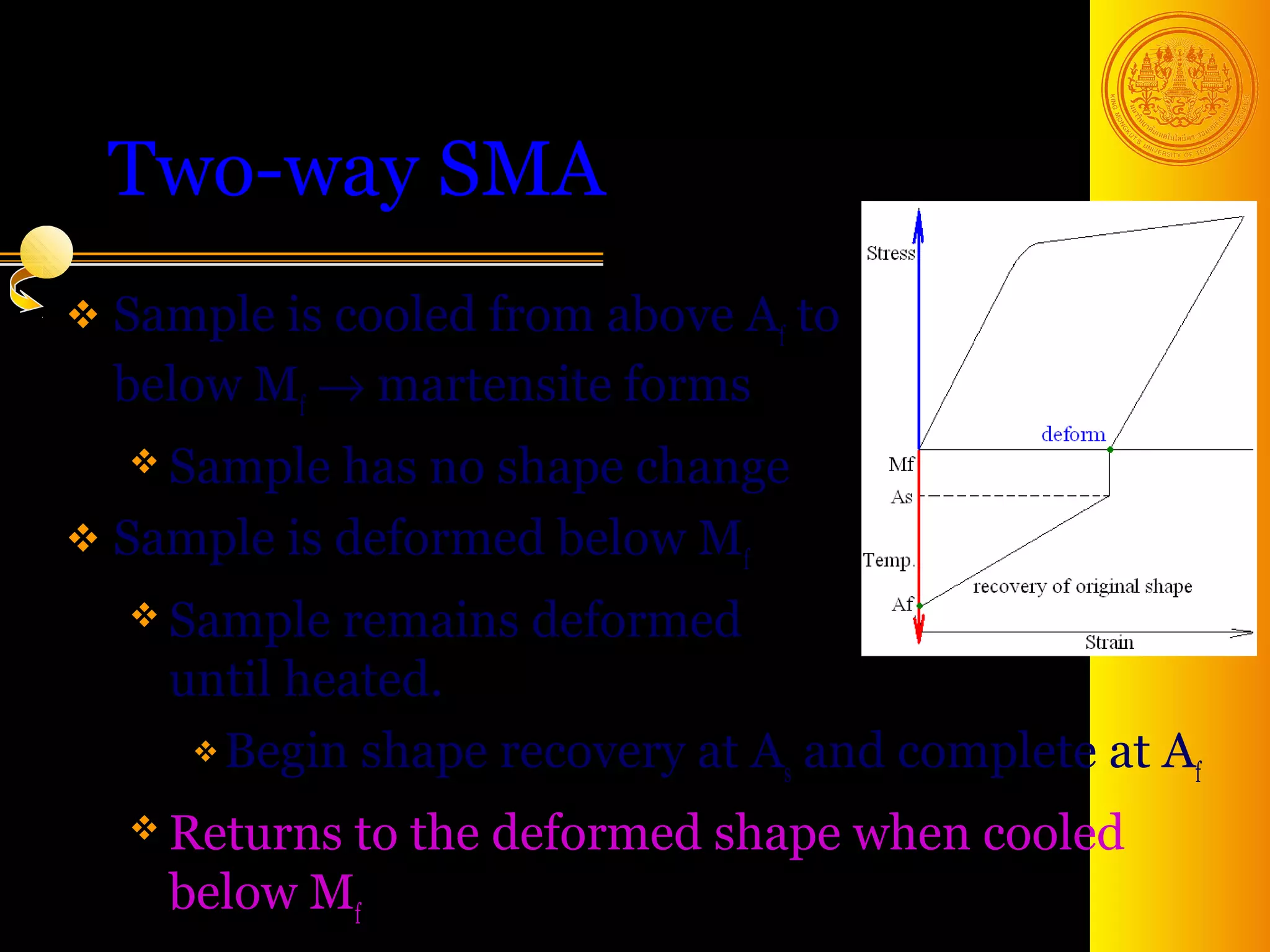

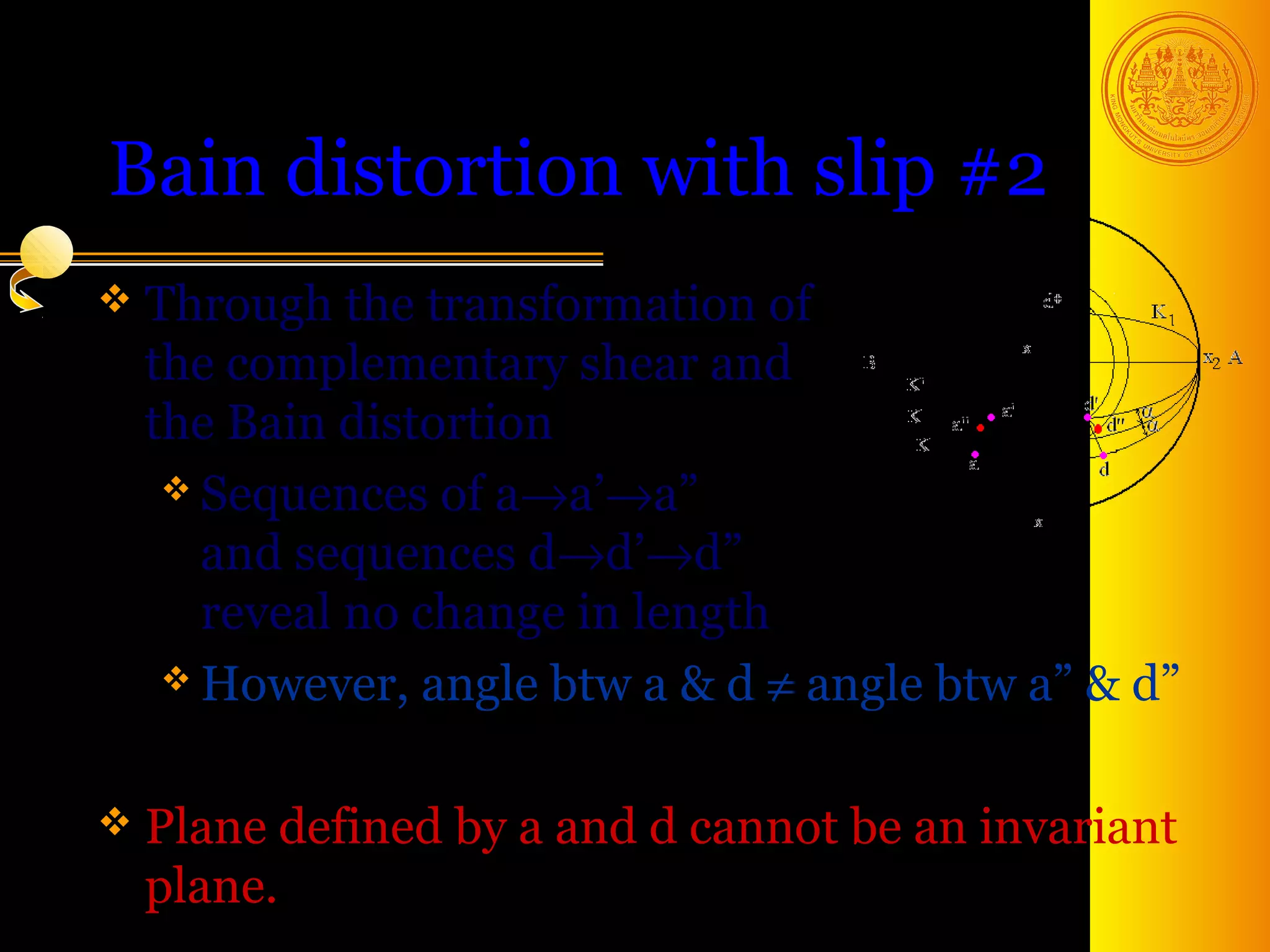

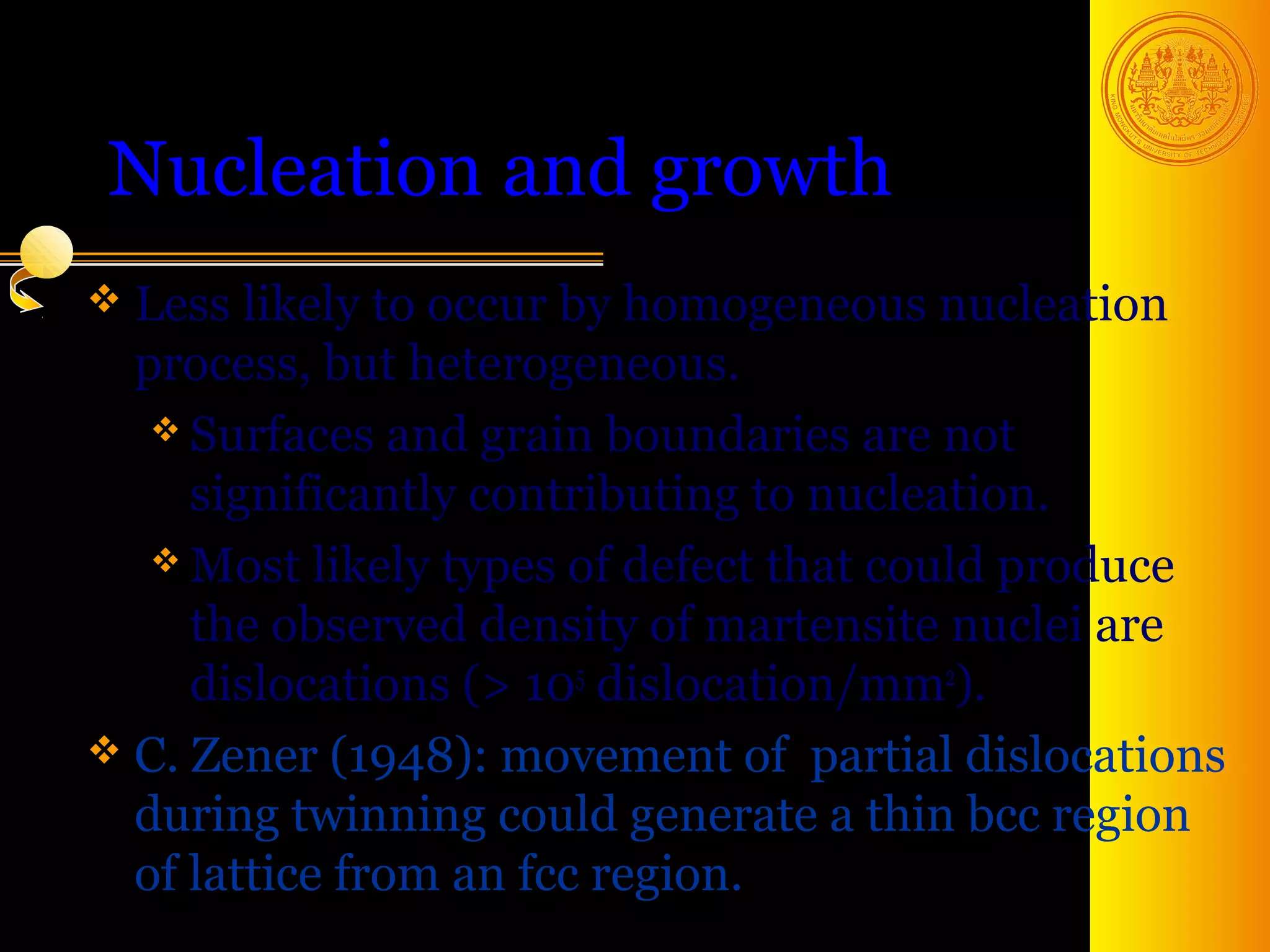

![Nucleation and growth

Dissociation of a dislocation

into 2 partials is favorable

→ lower strain energy.

r r r

To generate b1 = b2 + b3

bcc structure, a a a

[ 110] = [ 211] + 121

the requirements are that all 2 6 6

green atoms move (shear)

a

forward by 12 [ 211] and an

additional dilatation

to correct lattice spacings. 39](https://image.slidesharecdn.com/mt610phasetransformationsinsolidsiv-130211133504-phpapp02/75/Mt-610-phasetransformationsinsolids_iv-39-2048.jpg)