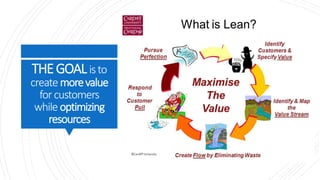

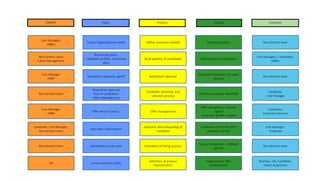

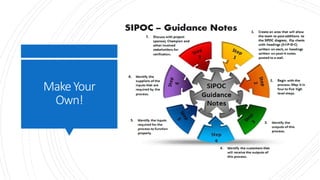

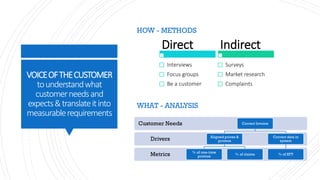

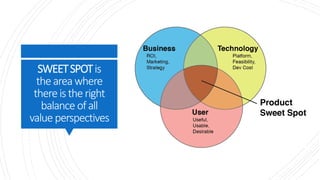

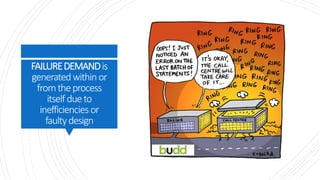

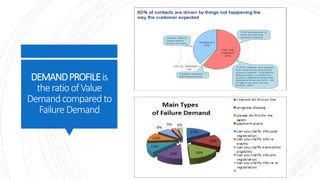

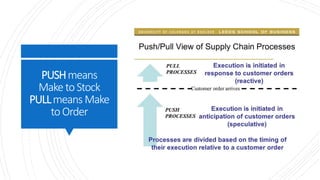

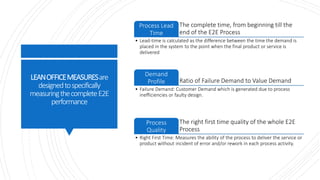

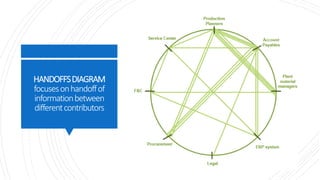

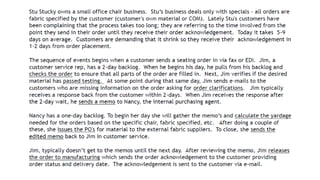

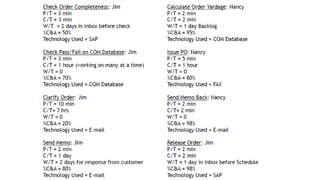

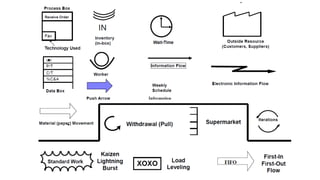

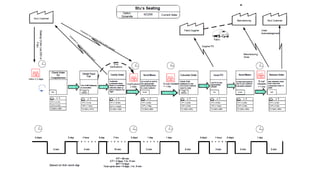

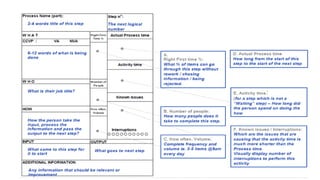

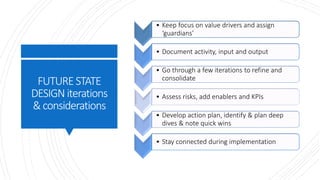

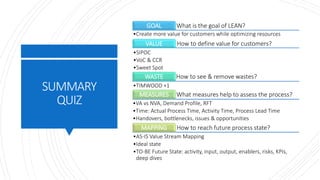

The document provides an overview of Lean concepts and tools. It explains that the goal of Lean is to create more value for customers while optimizing resources. It describes how to define value through tools like SIPOC, VoC and identifying the sweet spot. It also explains how to identify and remove wastes using techniques like TIMWOOD. The document outlines various measures that can be used to assess processes, including value-added vs non-value added activities, demand profile, and right first time. Finally, it discusses how value stream mapping can be used to design an ideal future state process and reach that desired future state.