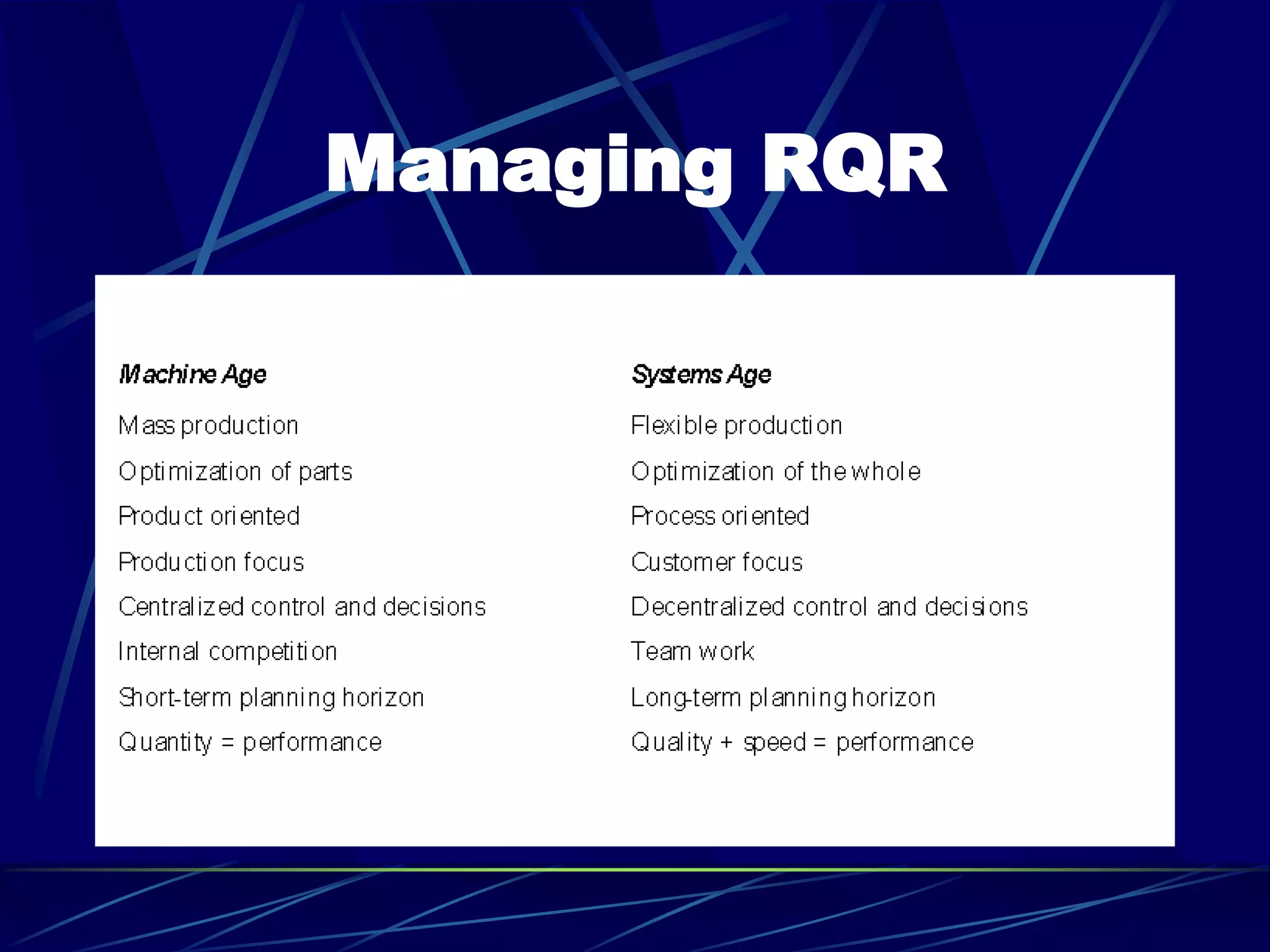

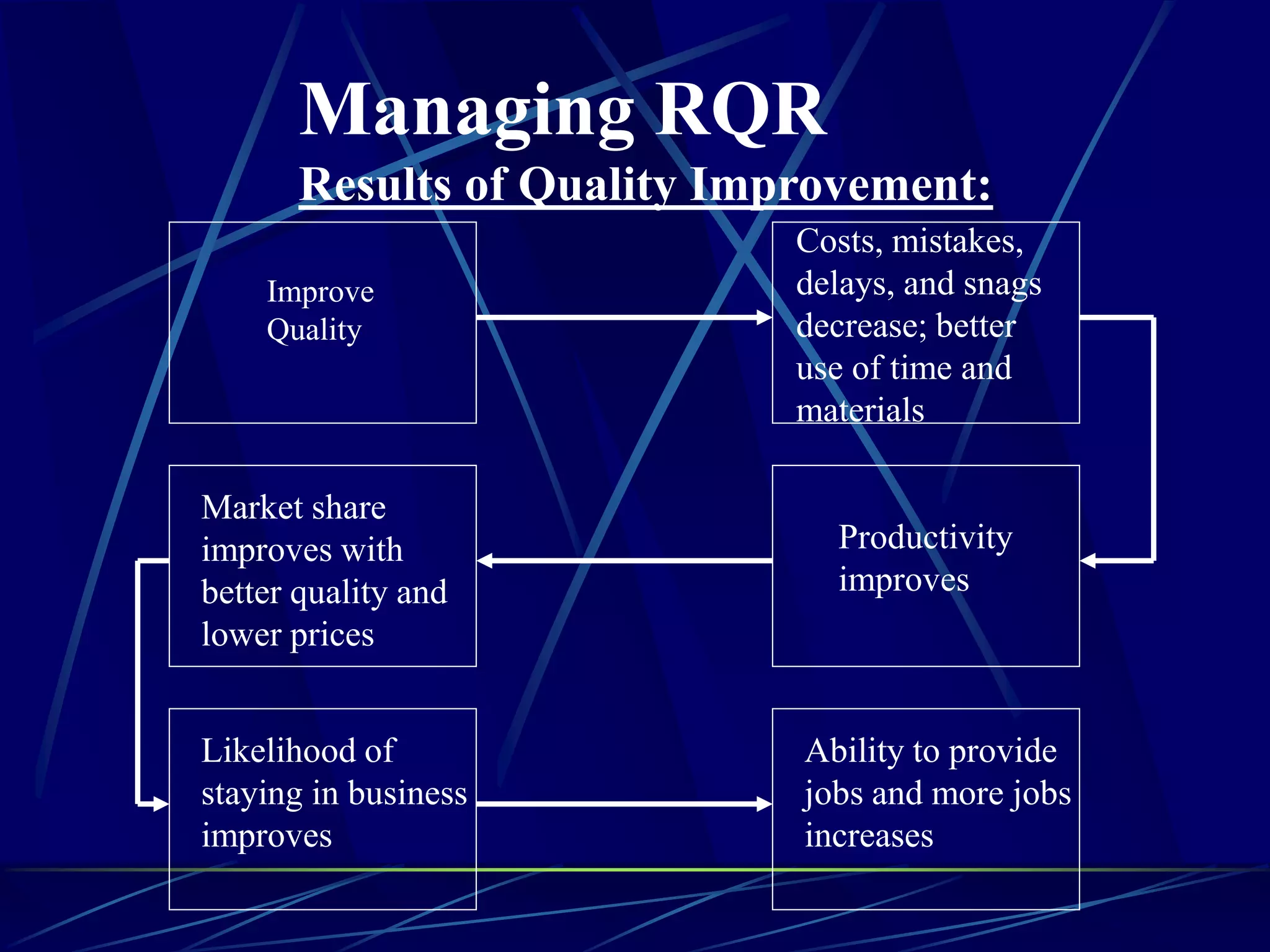

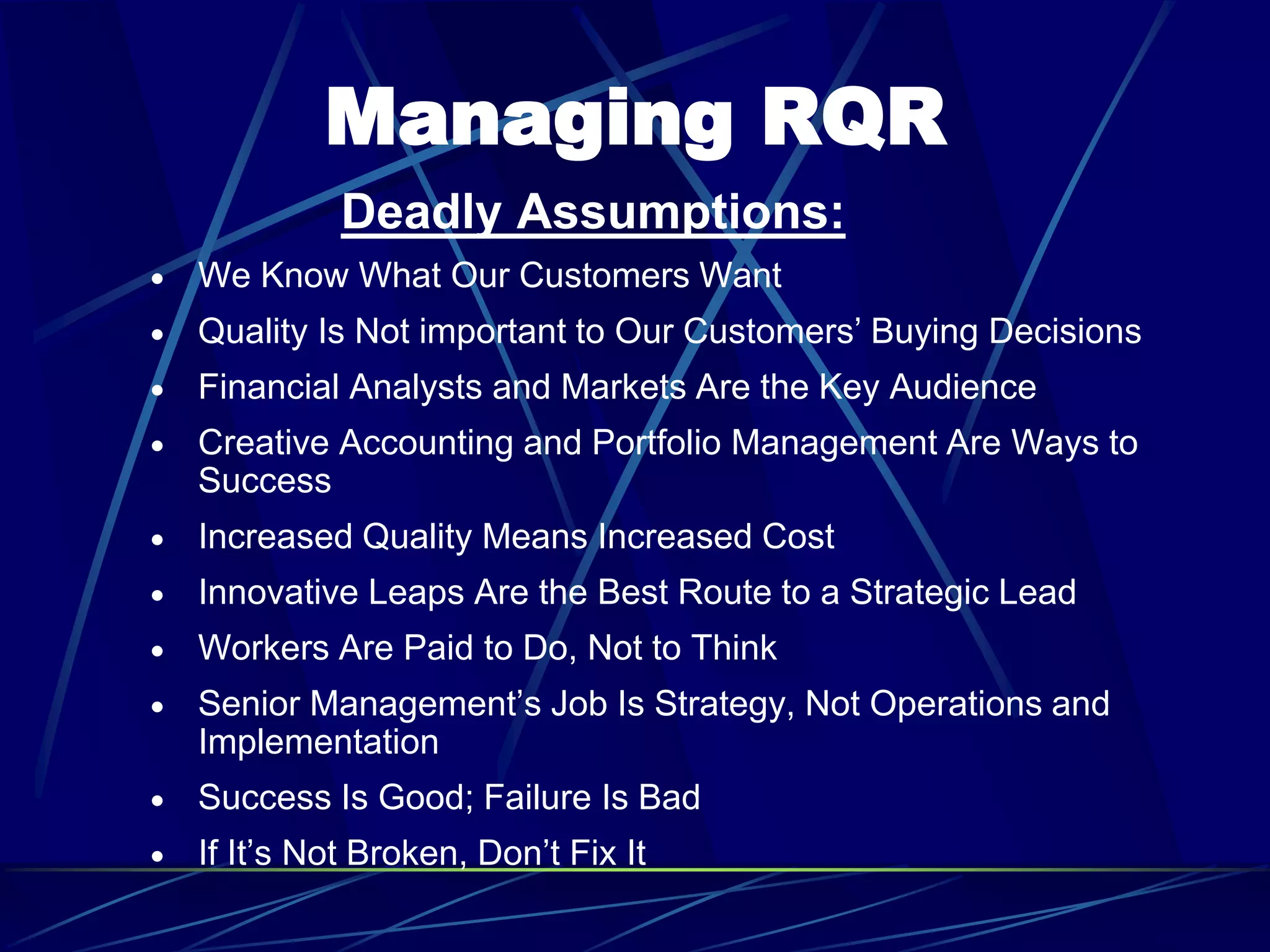

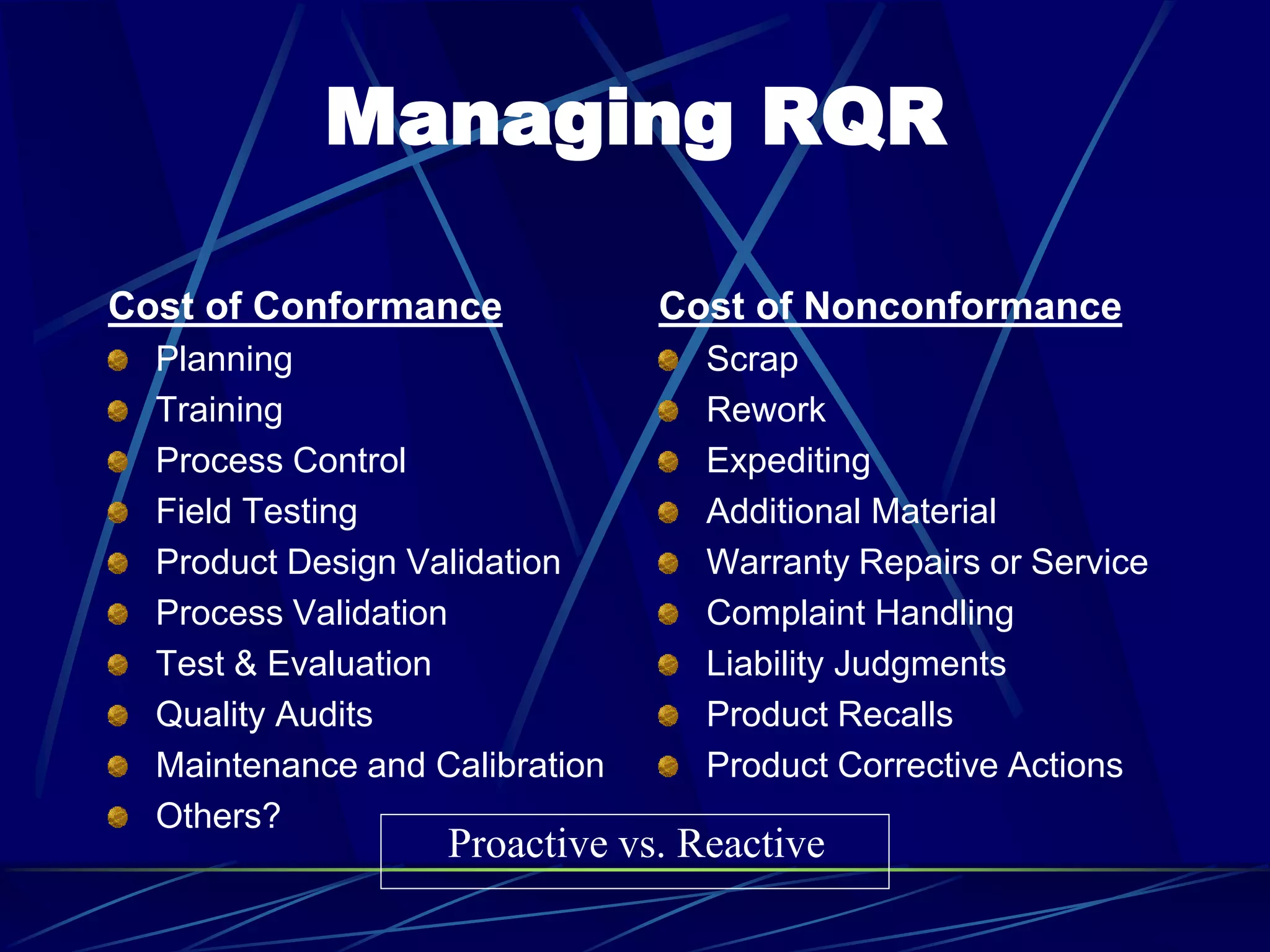

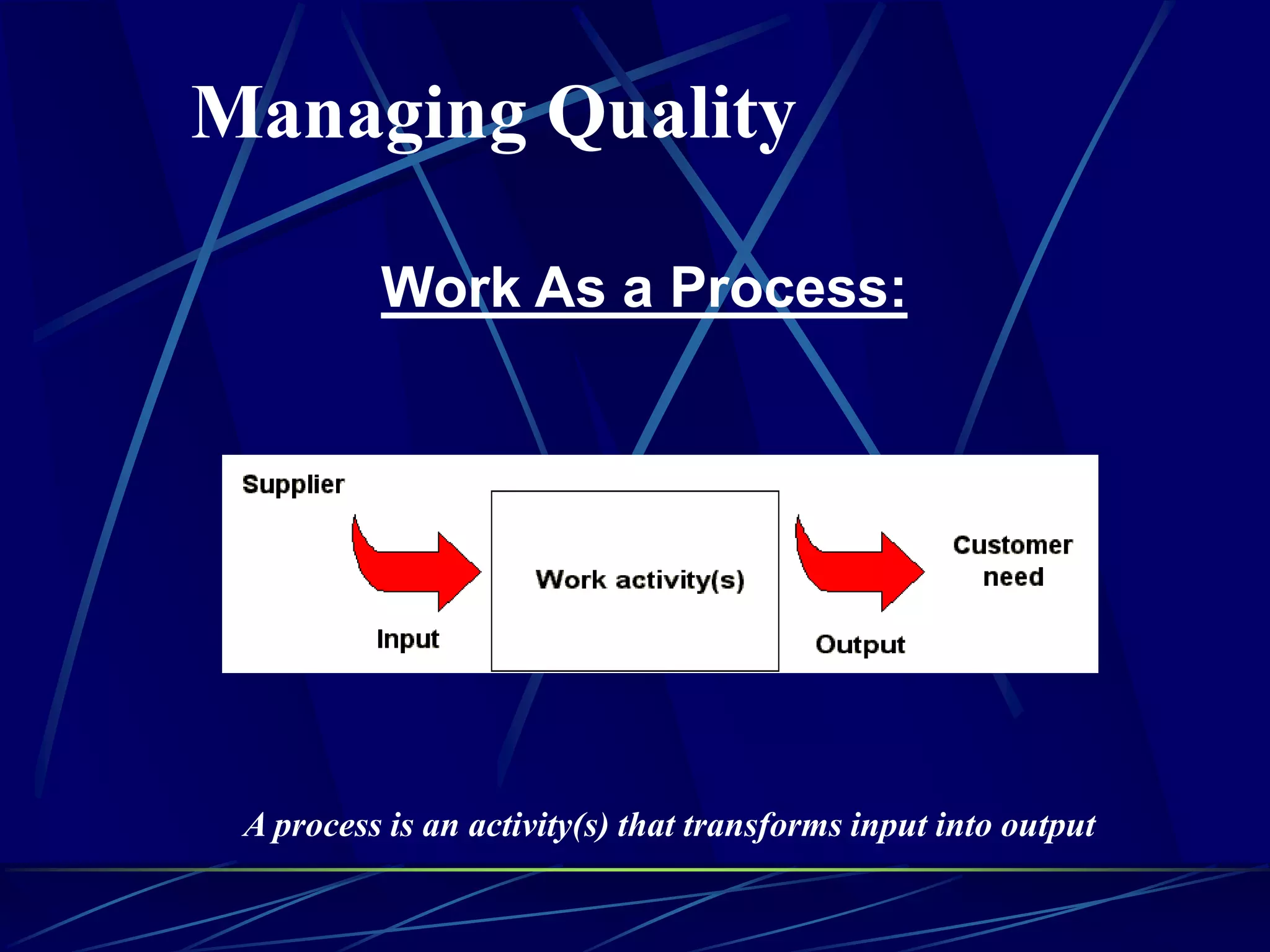

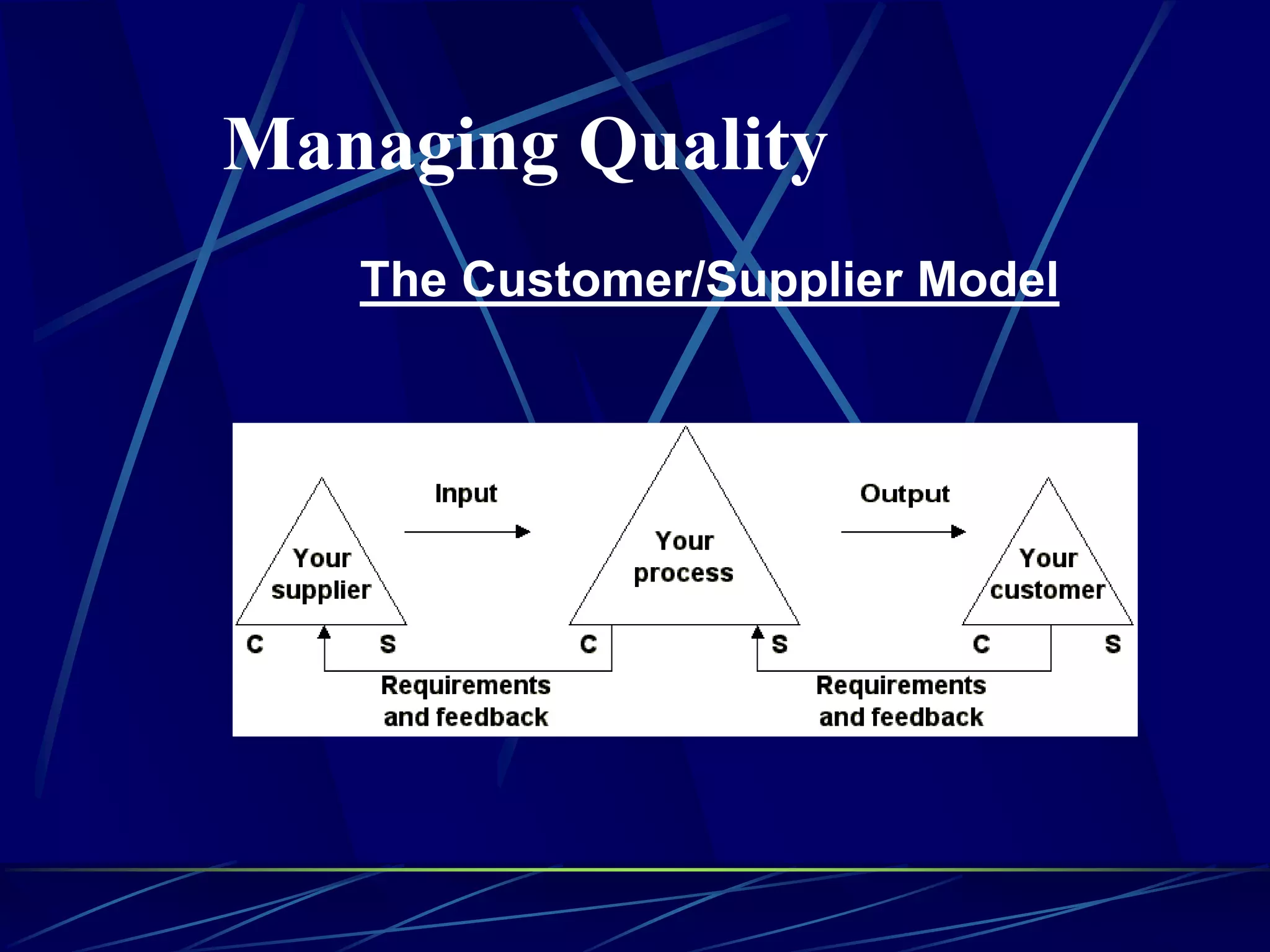

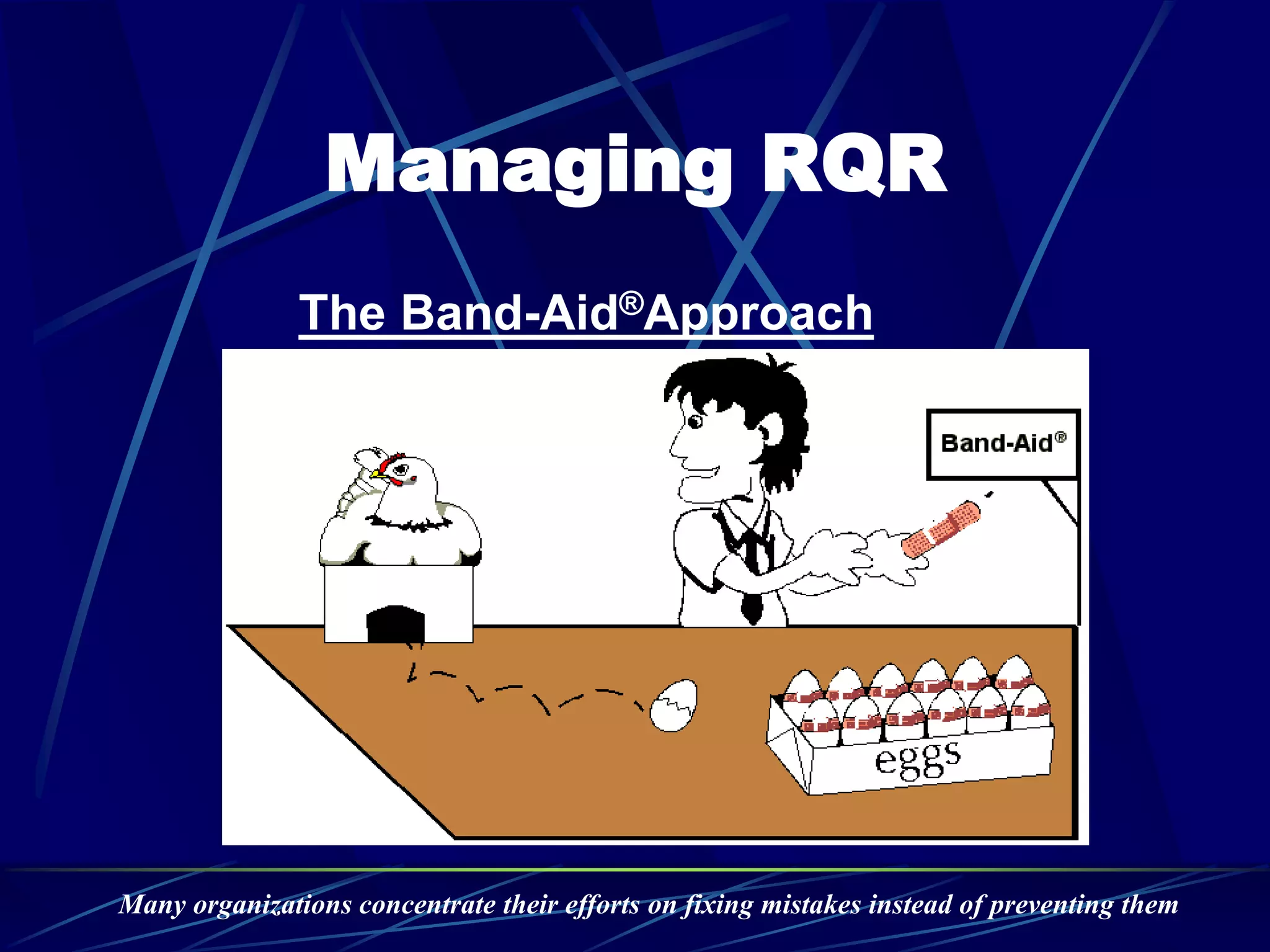

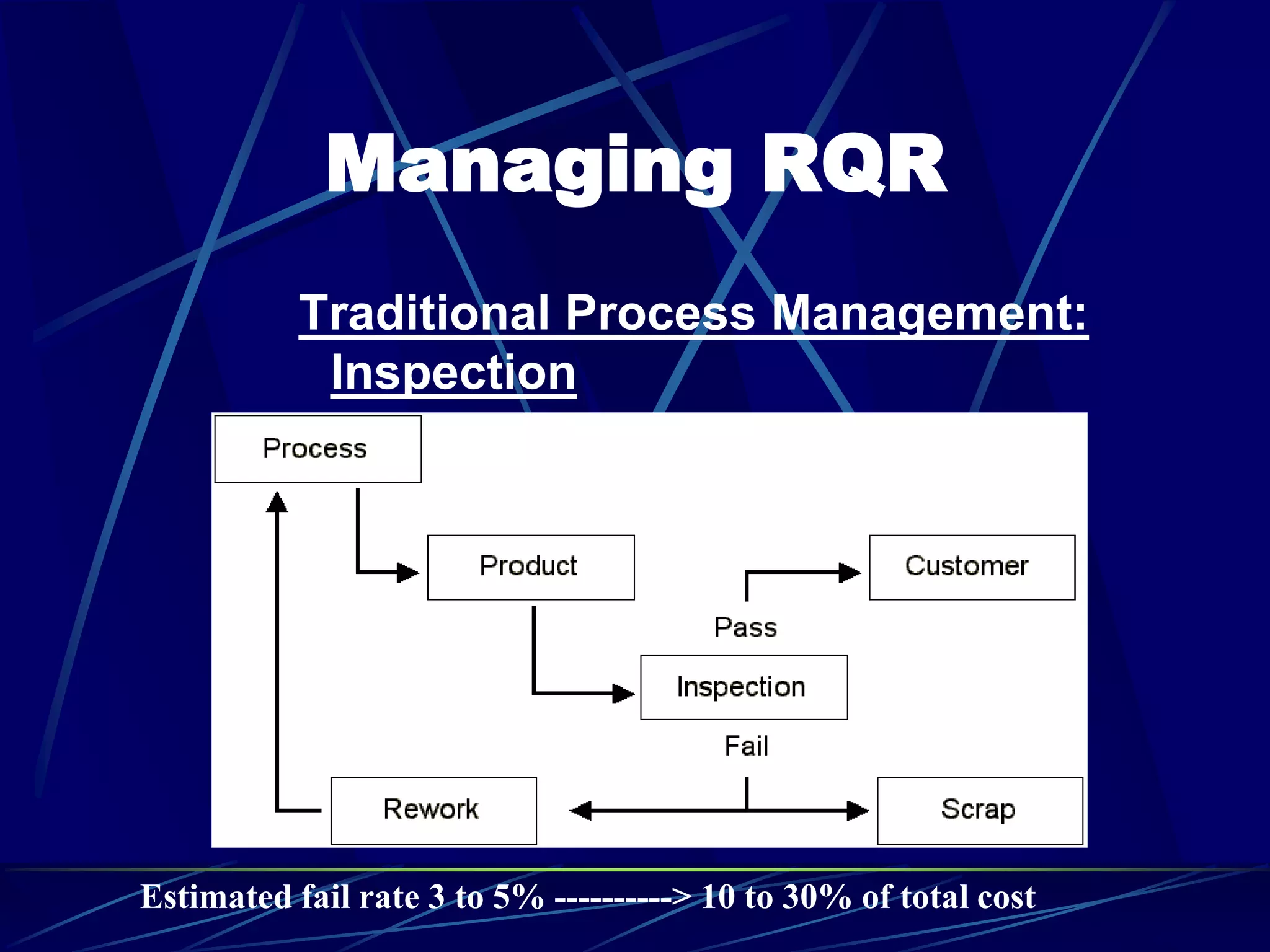

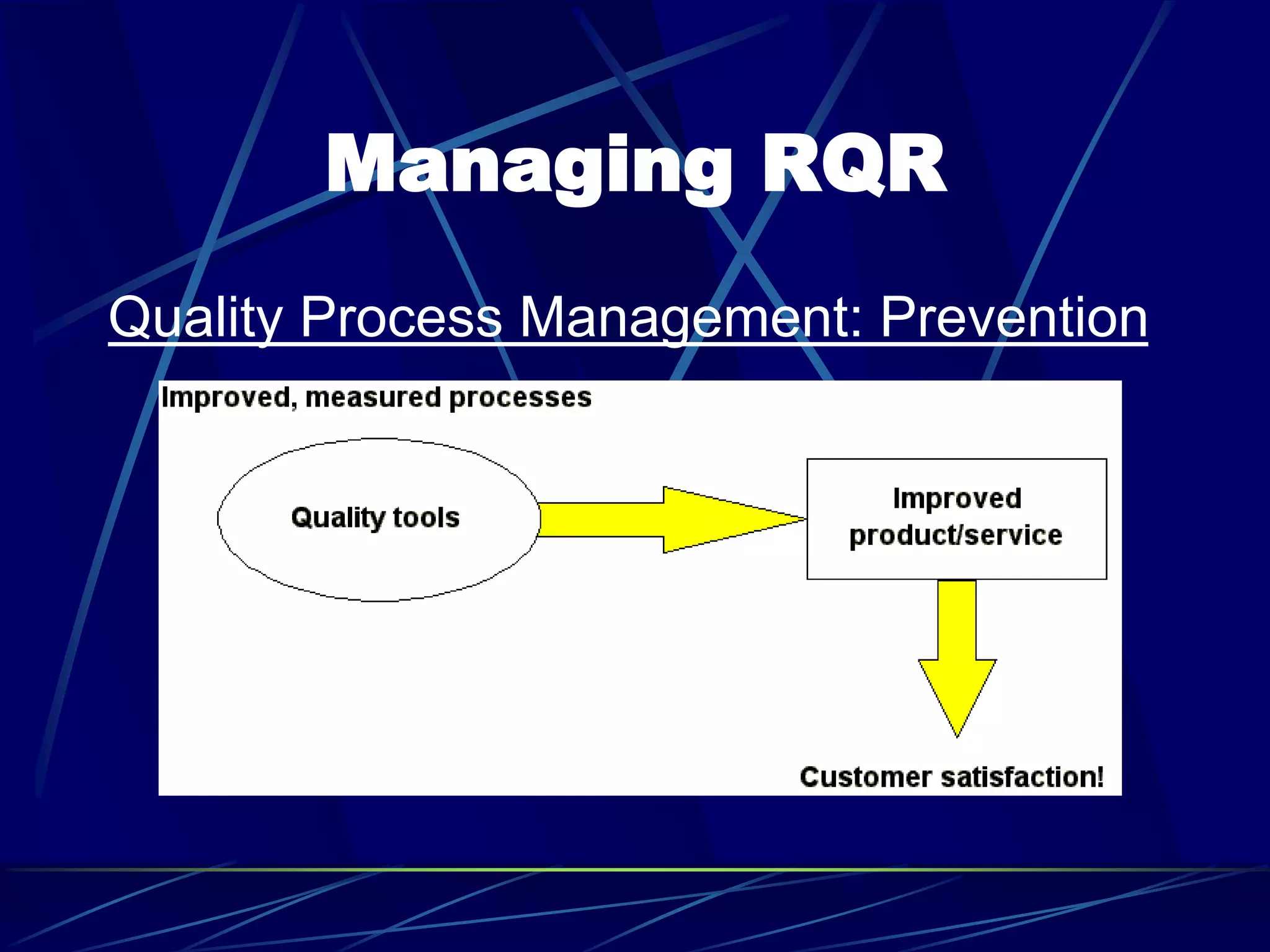

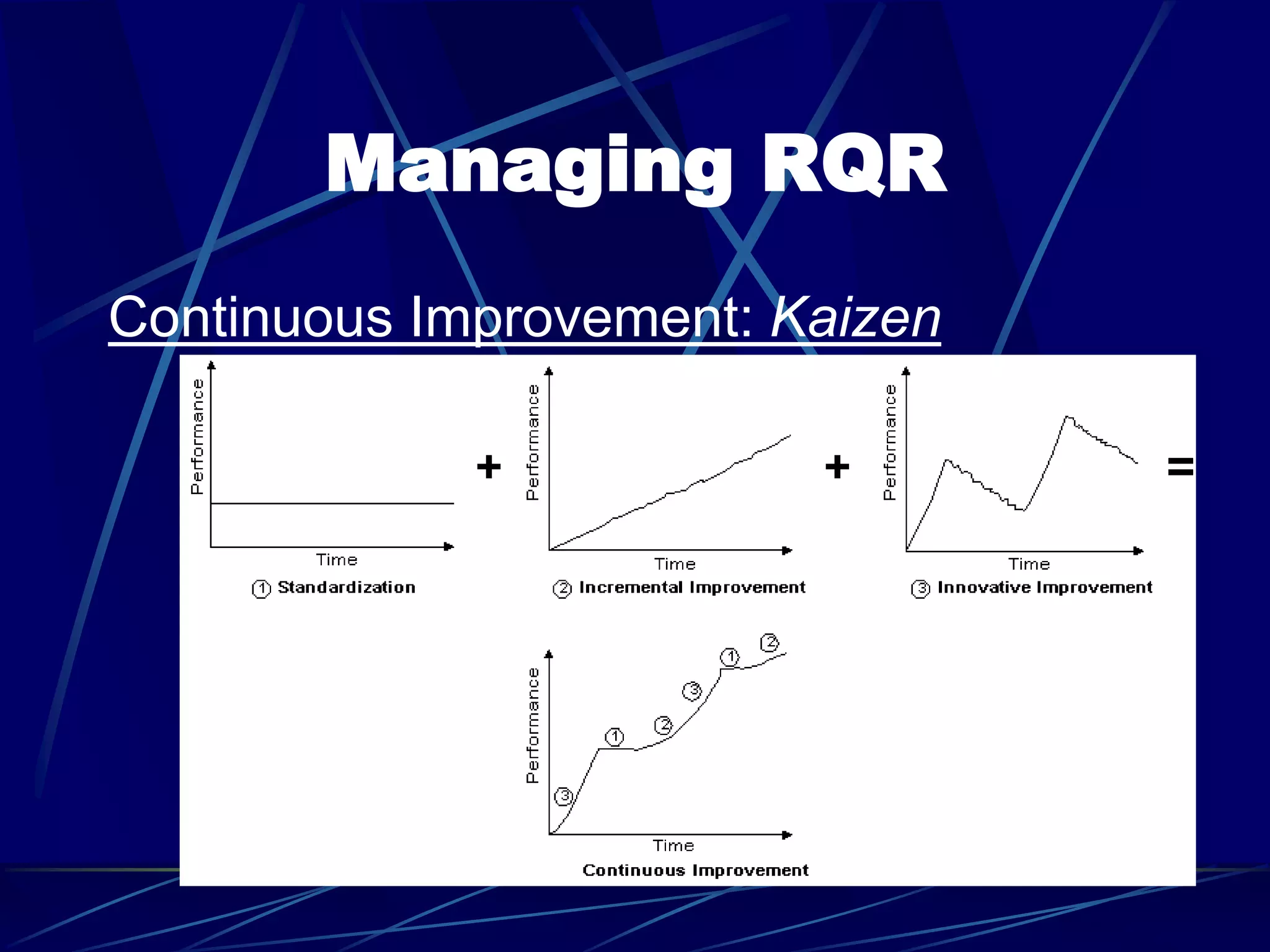

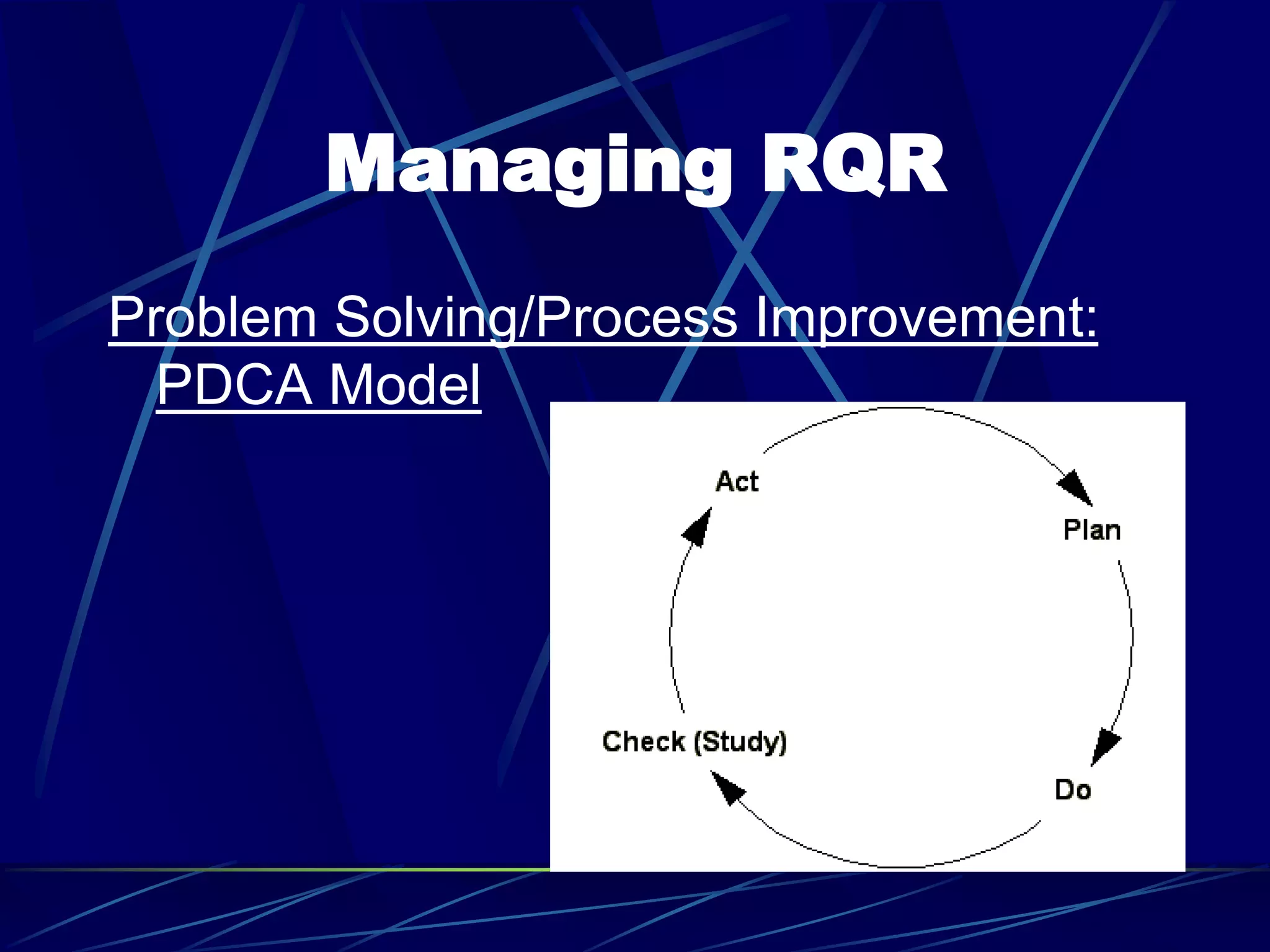

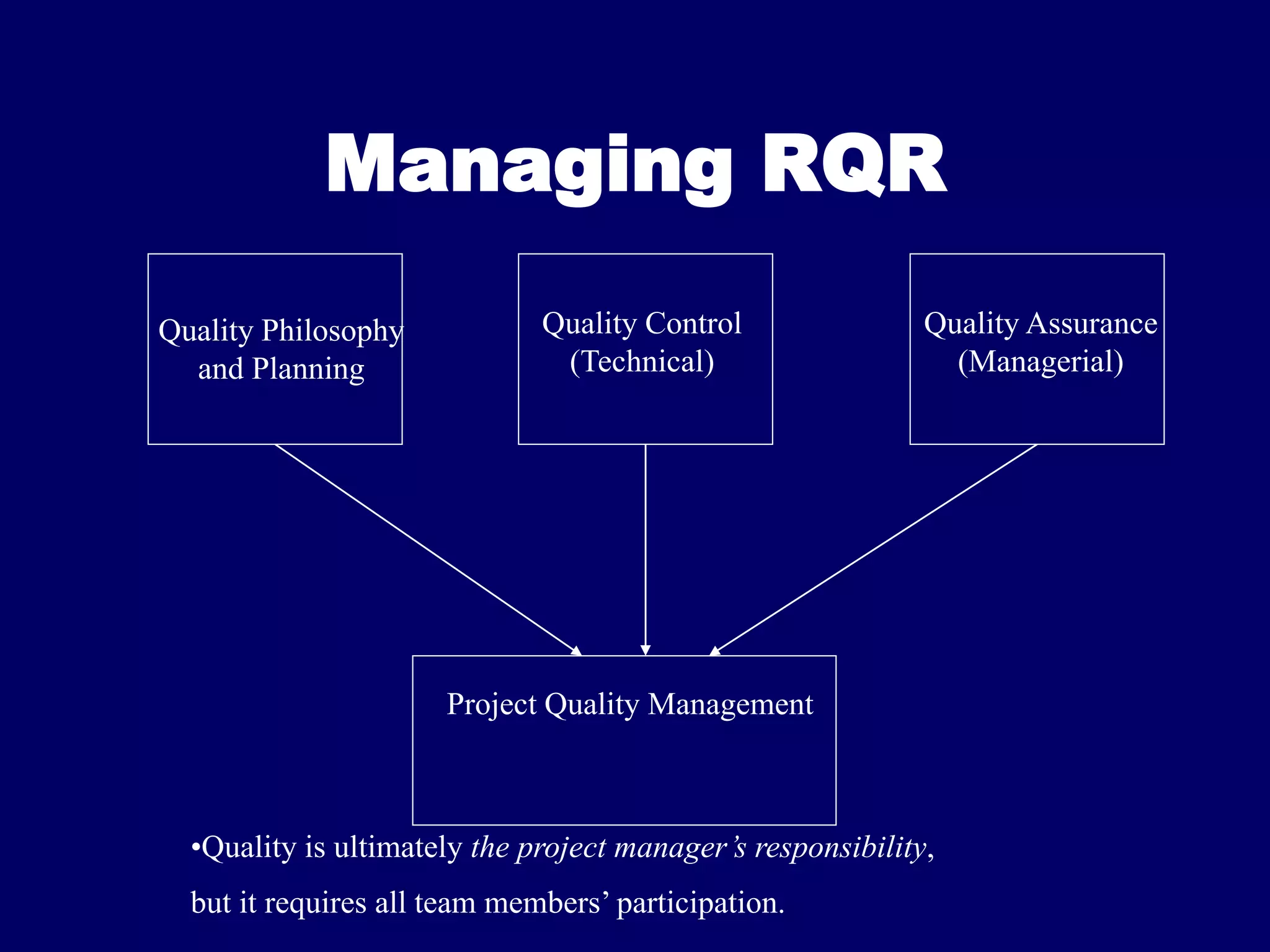

The document outlines the principles and practices of managing quality in organizations, emphasizing the importance of customer focus, effective leadership, and continuous improvement. It discusses the role of project managers in ensuring that quality is prioritized and integrated into all processes, while also addressing the cost of quality and the significance of system-based improvements. Key strategies include engaging employees at all levels, using data-driven decision-making, and fostering a culture of quality throughout the organization.