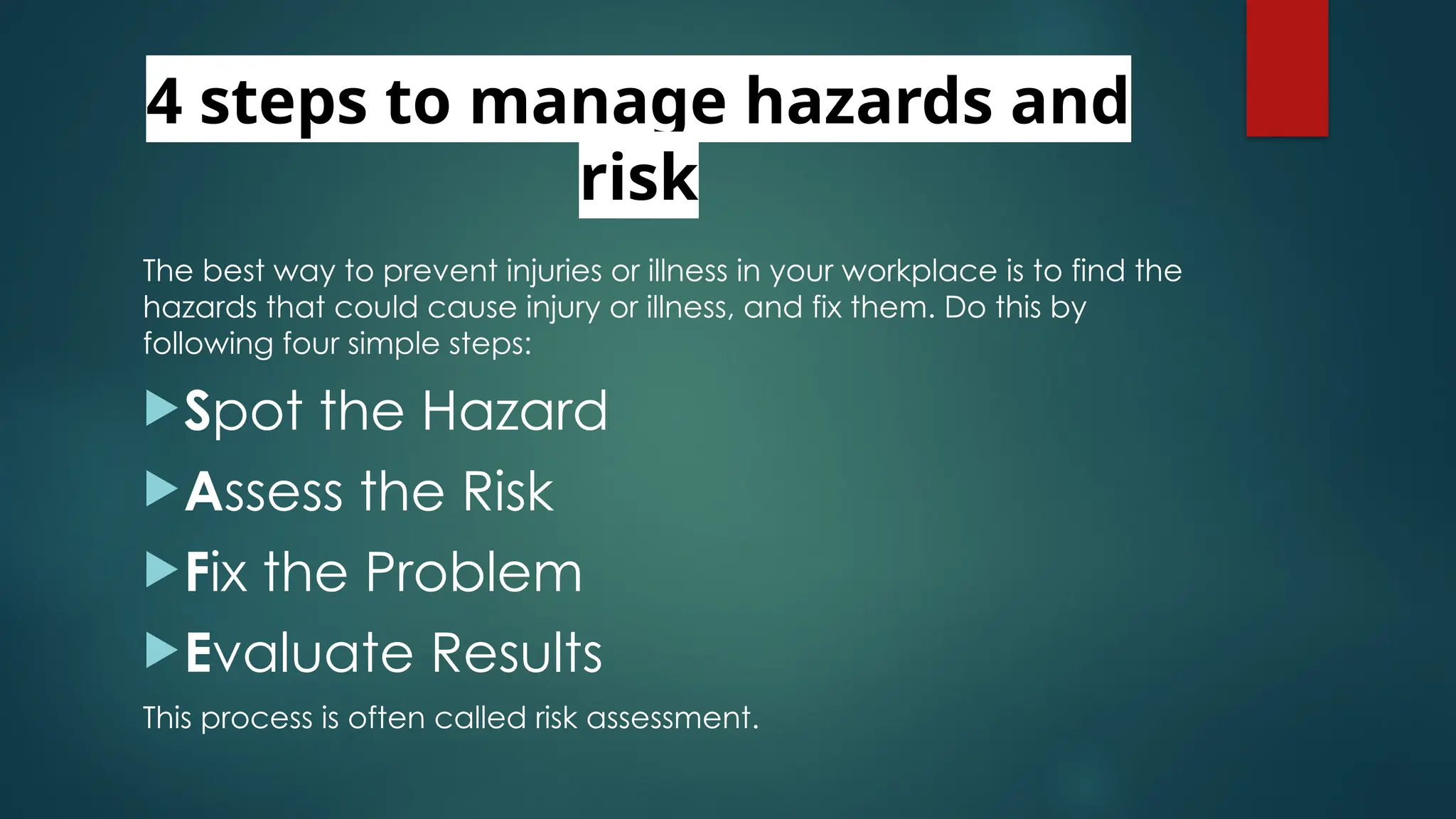

The document discusses risk management in the context of safety, security, and sanitation by identifying hazards, which are potential sources of harm, and classifying them into categories such as natural or technological. It outlines a four-step process for managing hazards: spotting the hazard, assessing risk, fixing the problem, and evaluating results, with various methods to eliminate or mitigate hazards. The document emphasizes the importance of proactive measures in workplace safety to prevent injuries and illnesses.