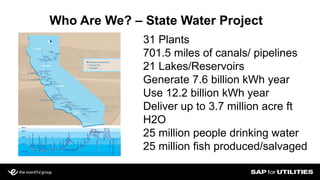

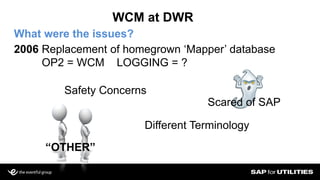

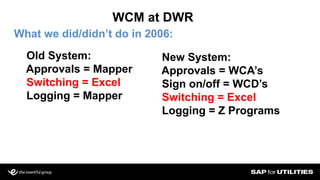

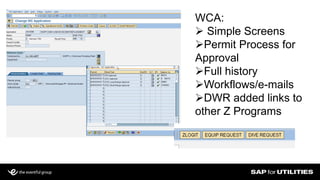

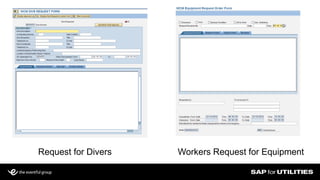

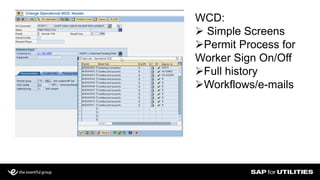

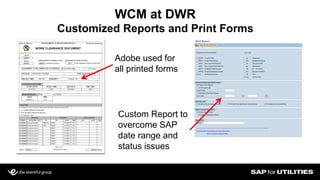

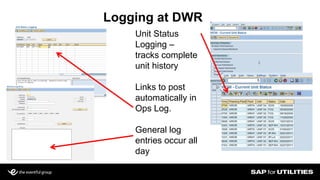

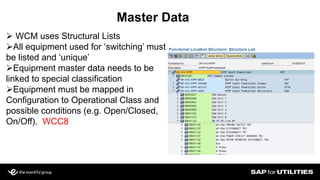

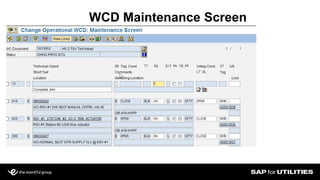

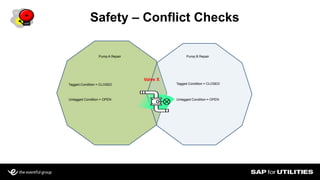

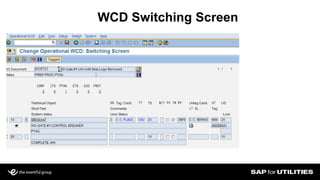

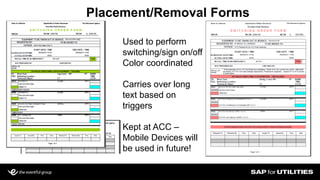

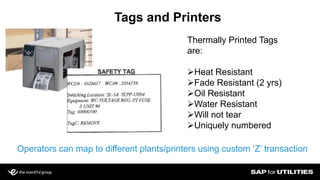

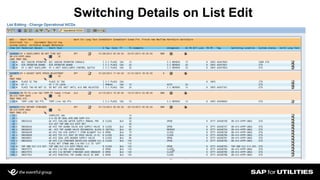

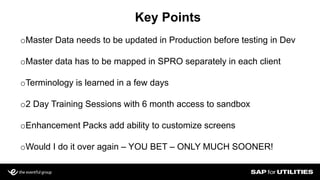

This document summarizes the operational switching program implemented at the California Department of Water Resources (DWR) to safely shut down hazardous energy sources for equipment maintenance. It discusses DWR's implementation of SAP's Work Clearance Management module, including developing master data, configuration, permit and logging screens, tagging printers, and testing. The program went live in 2012 and has resulted in fewer than 5 issues statewide with no operational near misses due to switching. Key lessons learned include the importance of extensive testing and updating master data.