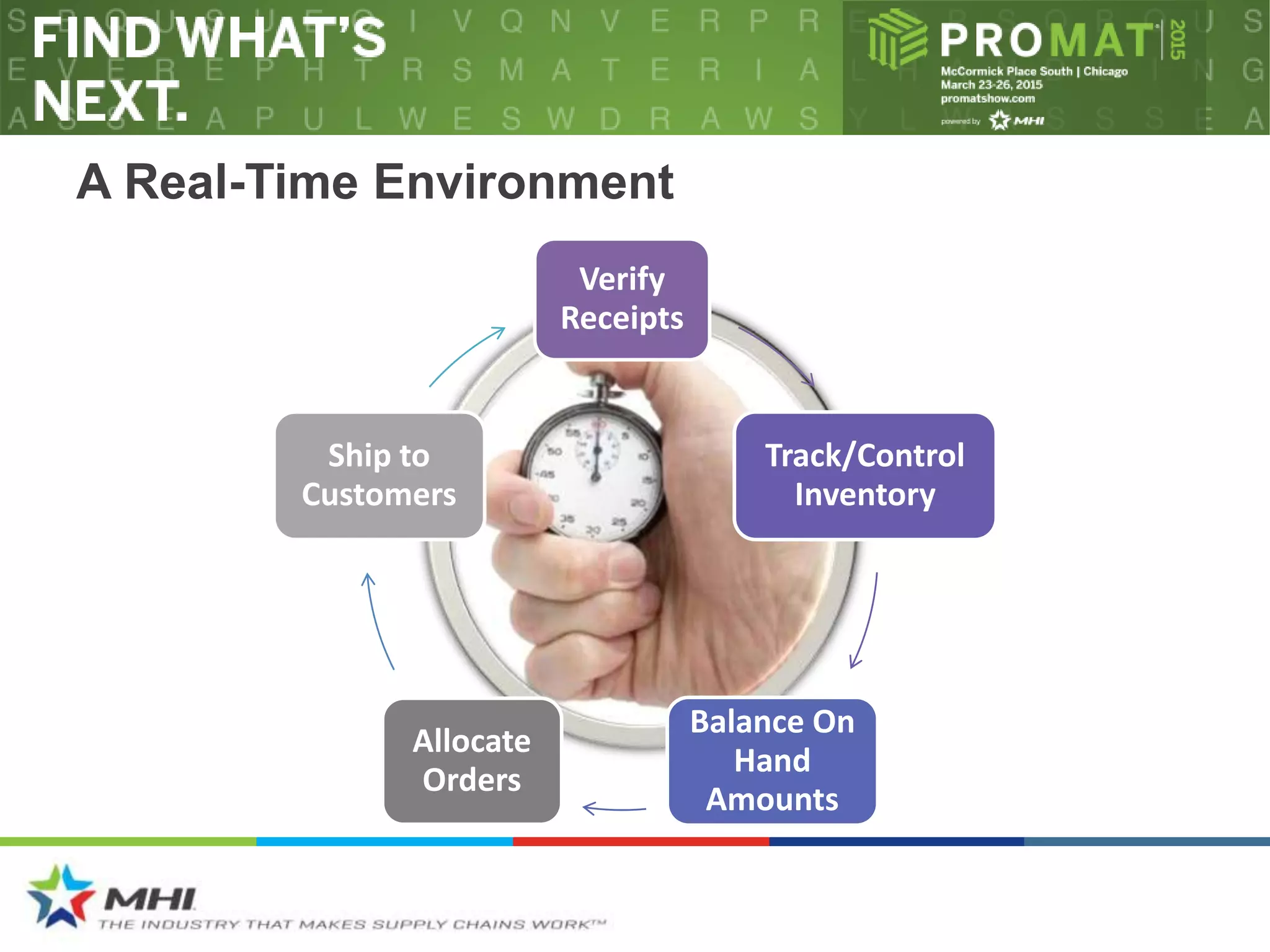

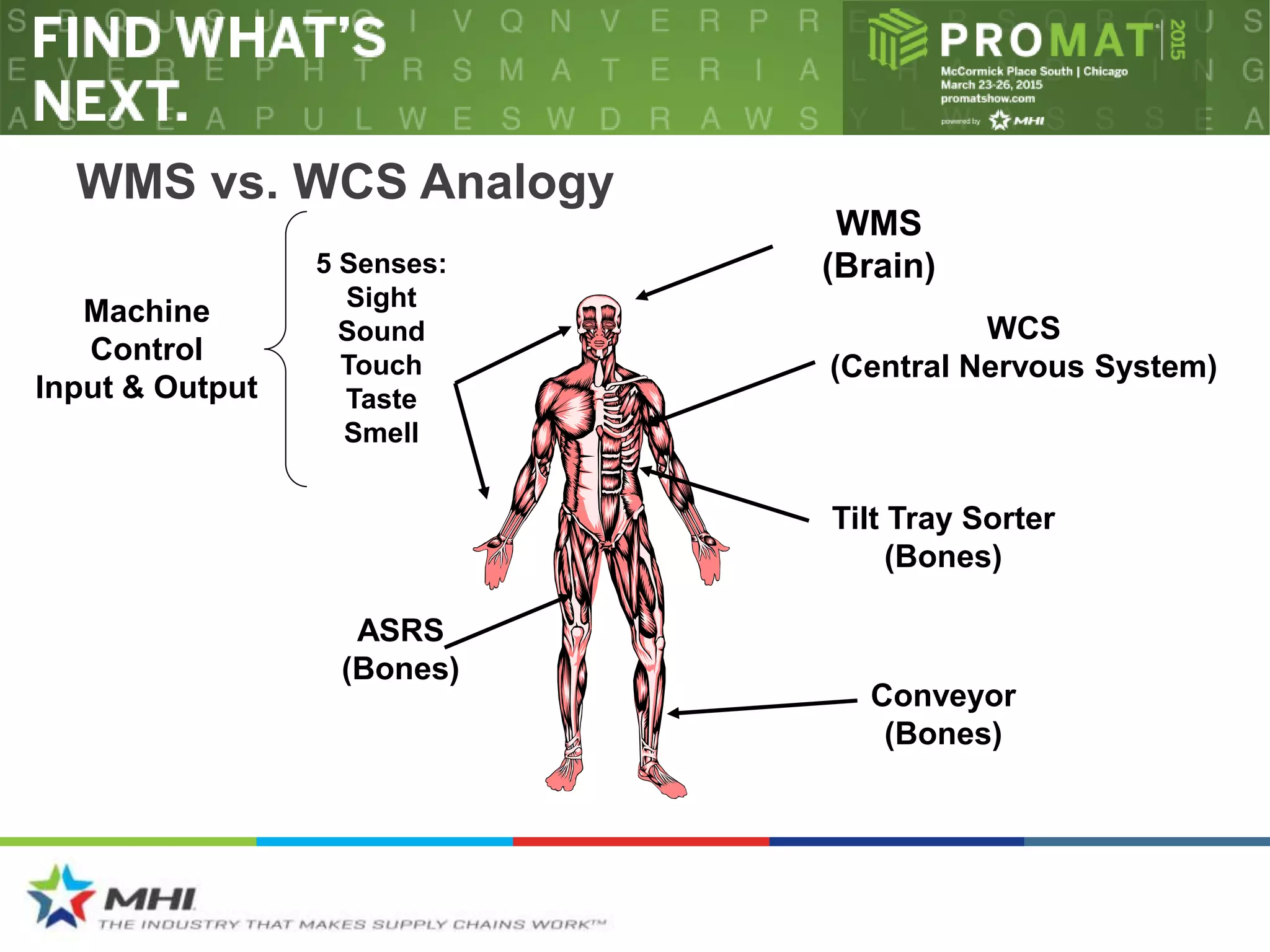

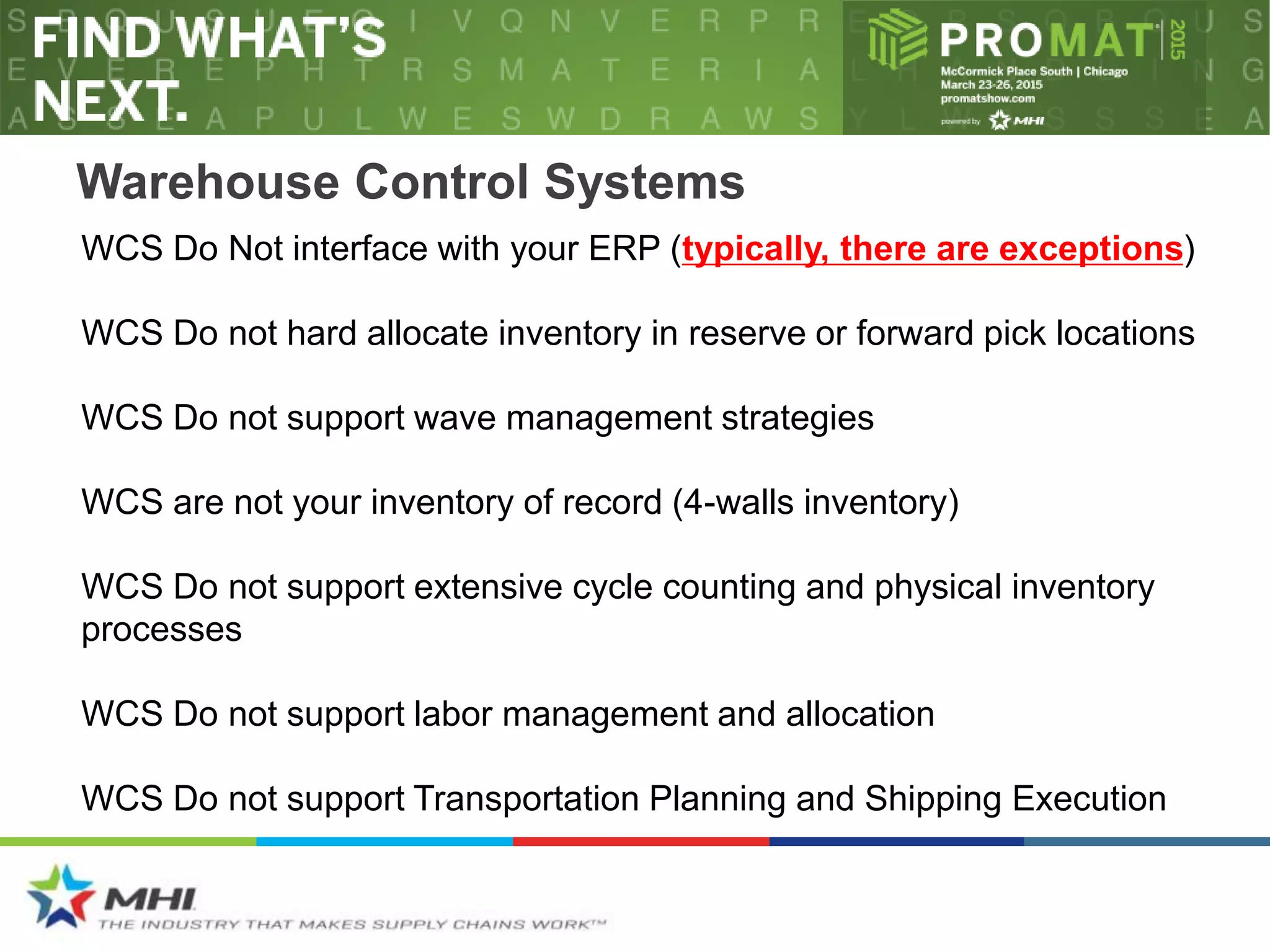

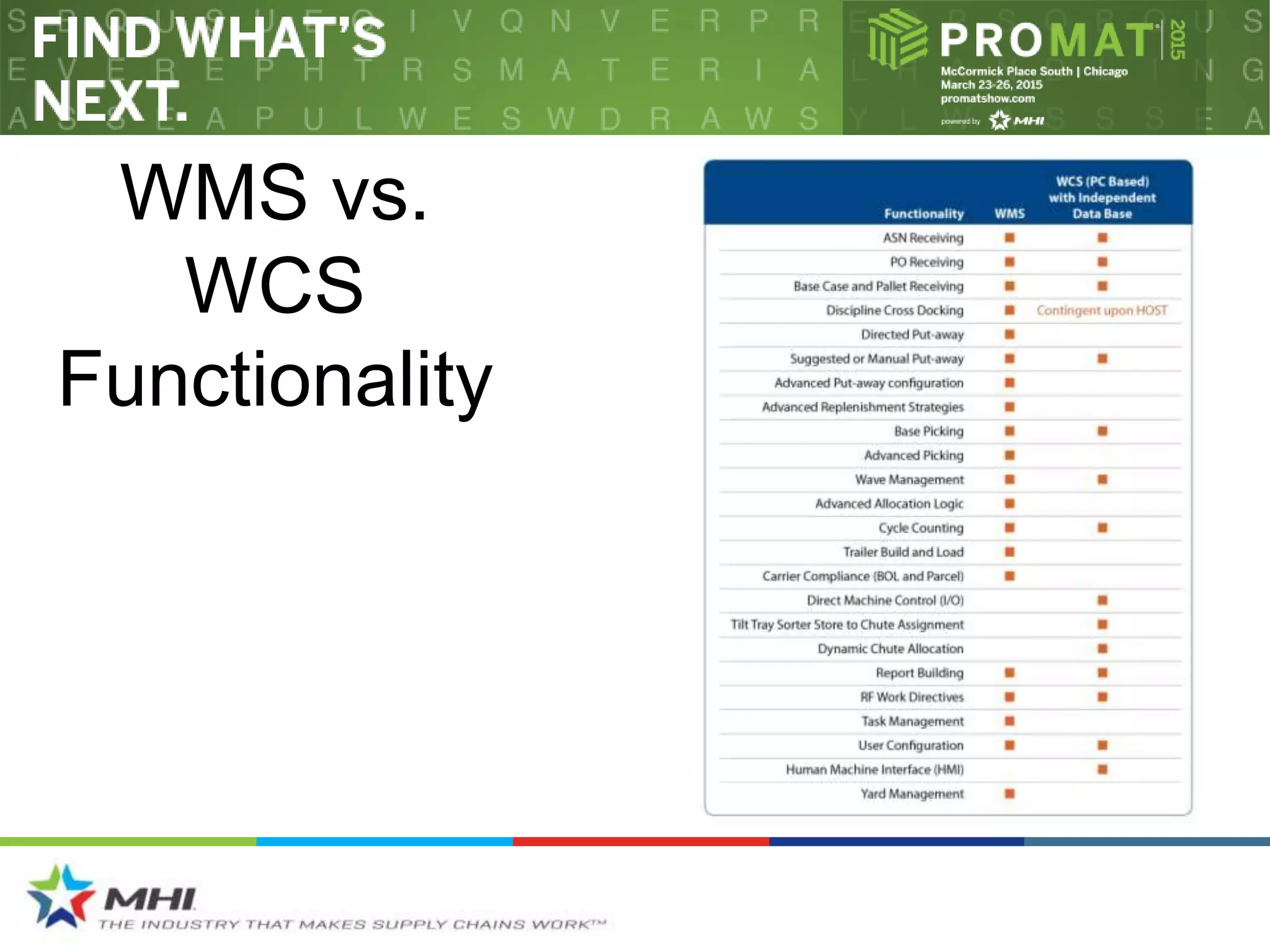

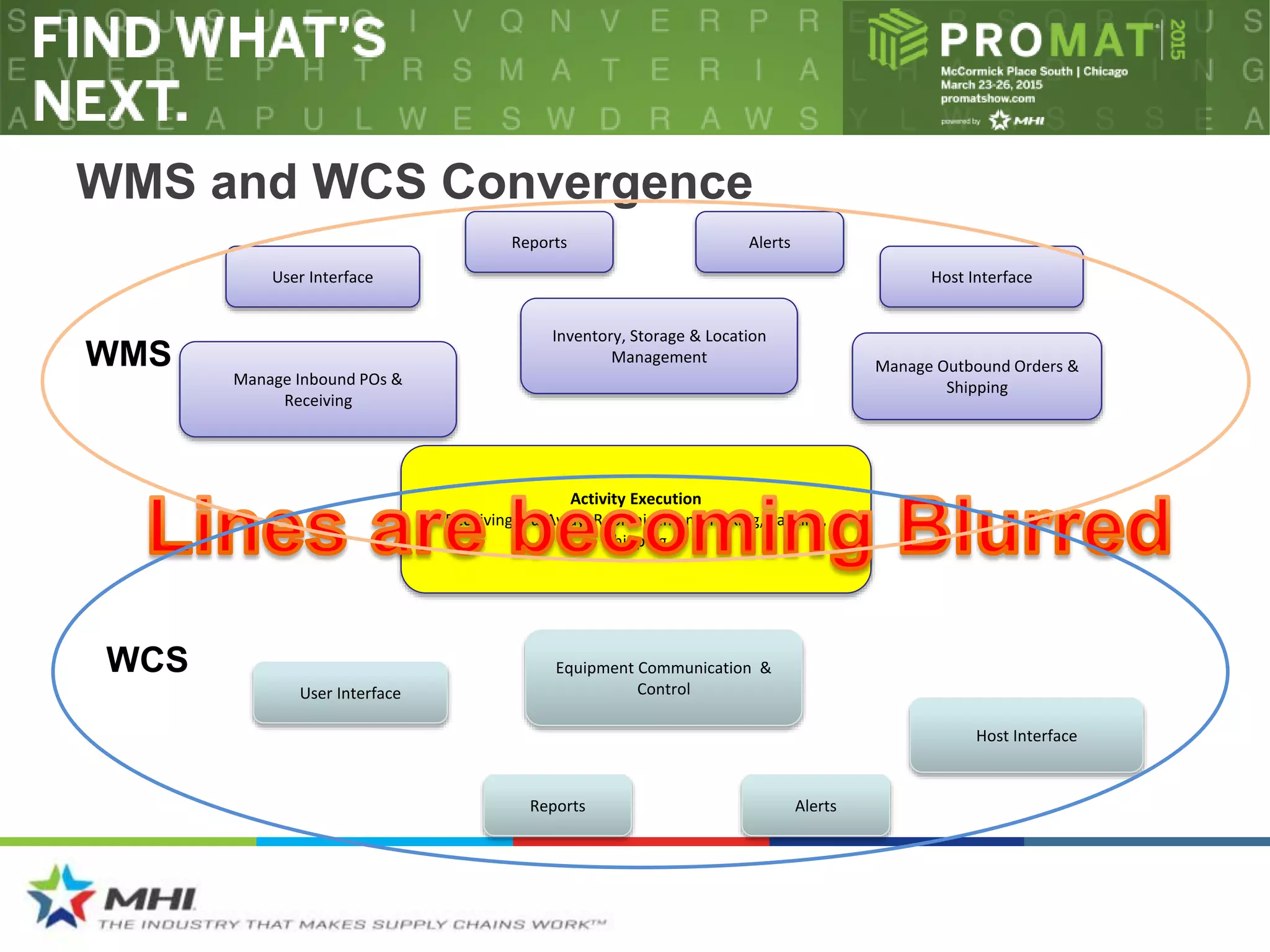

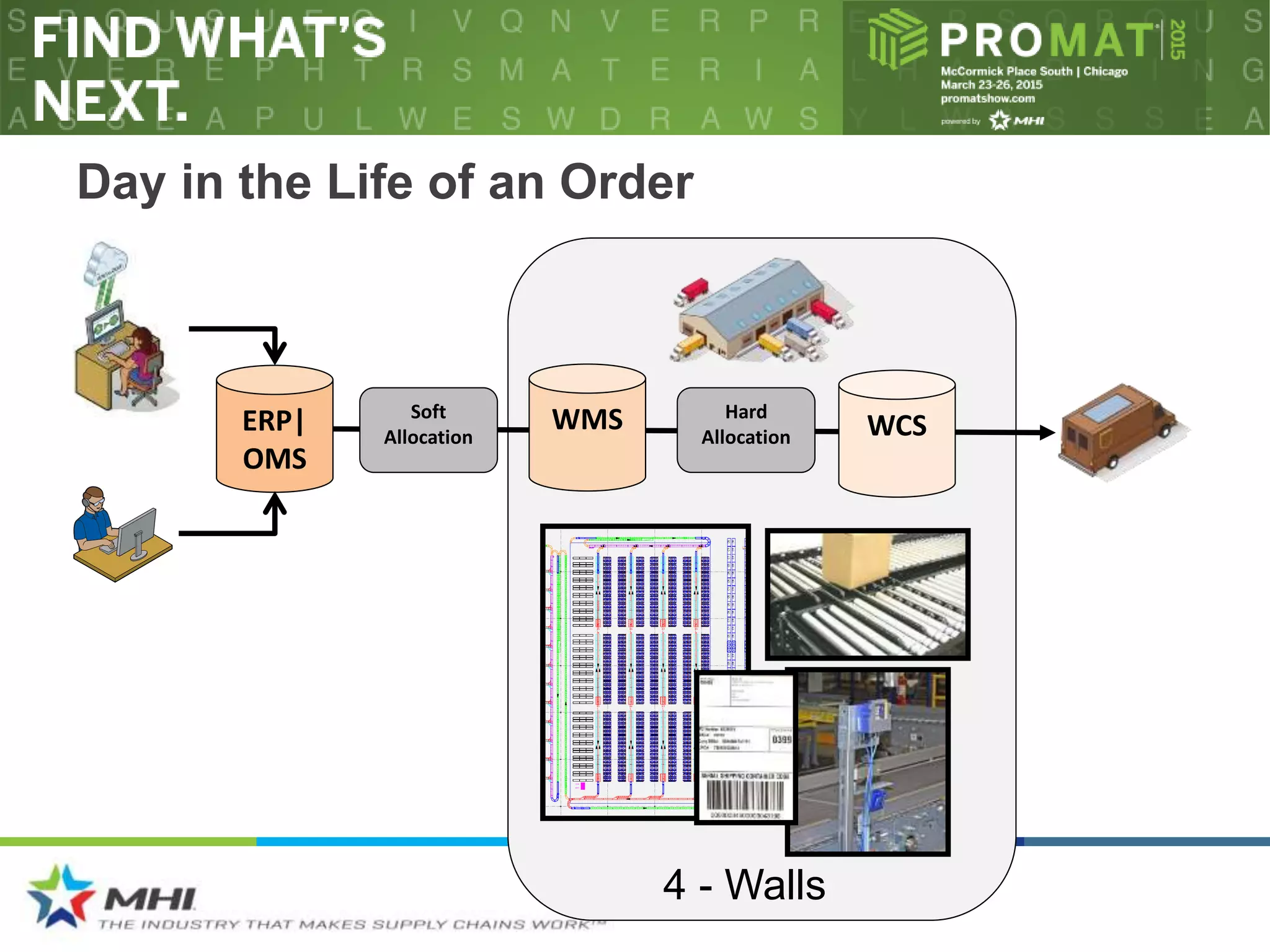

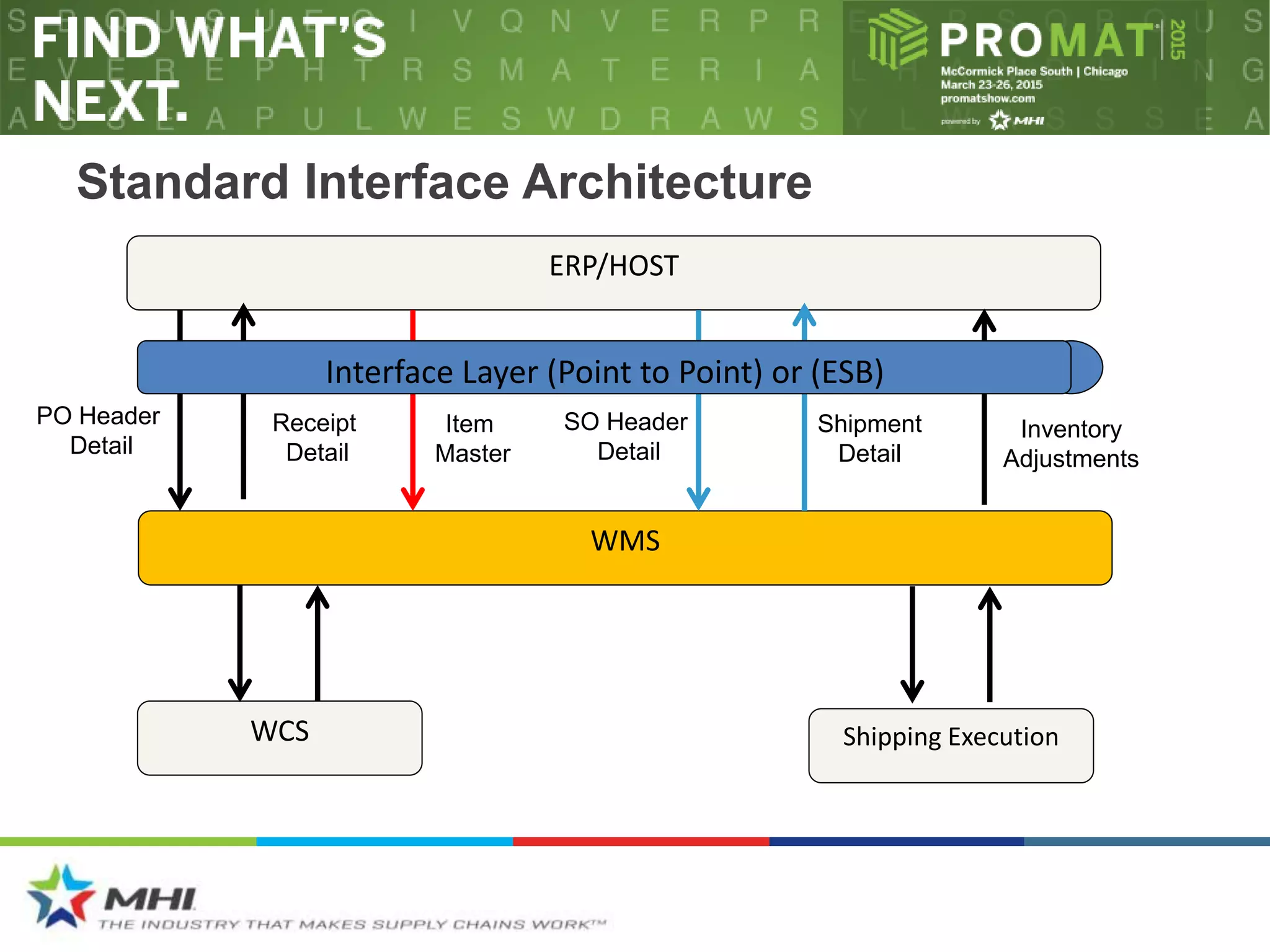

The document presents a detailed comparison between Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS), outlining their definitions, functionalities, and use cases. WMS is focused on inventory management within distribution centers, while WCS manages automated equipment and real-time communications for material handling. It also includes case studies and lessons learned for optimizing the application of WMS and WCS in business operations.