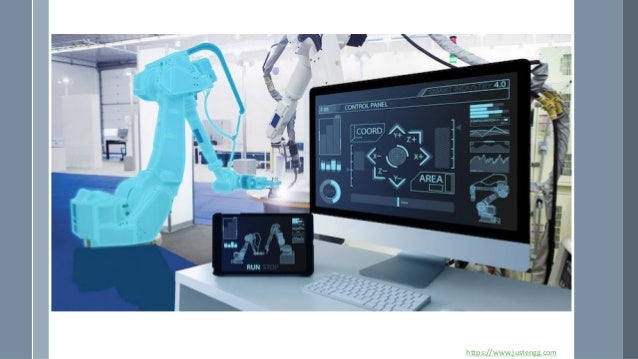

An HMI, or human-machine interface, allows humans to interact with machines and industrial processes. It provides visualization capabilities and interfaces through screens, allowing operators to monitor processes, view data, and control machines. Common HMI formats include built-in machine screens, computer monitors, and tablets. HMIs are widely used across industries like manufacturing, oil and gas, and more. Advanced HMI technologies now include touch screens, mobile access, remote monitoring, and edge-of-network capabilities.