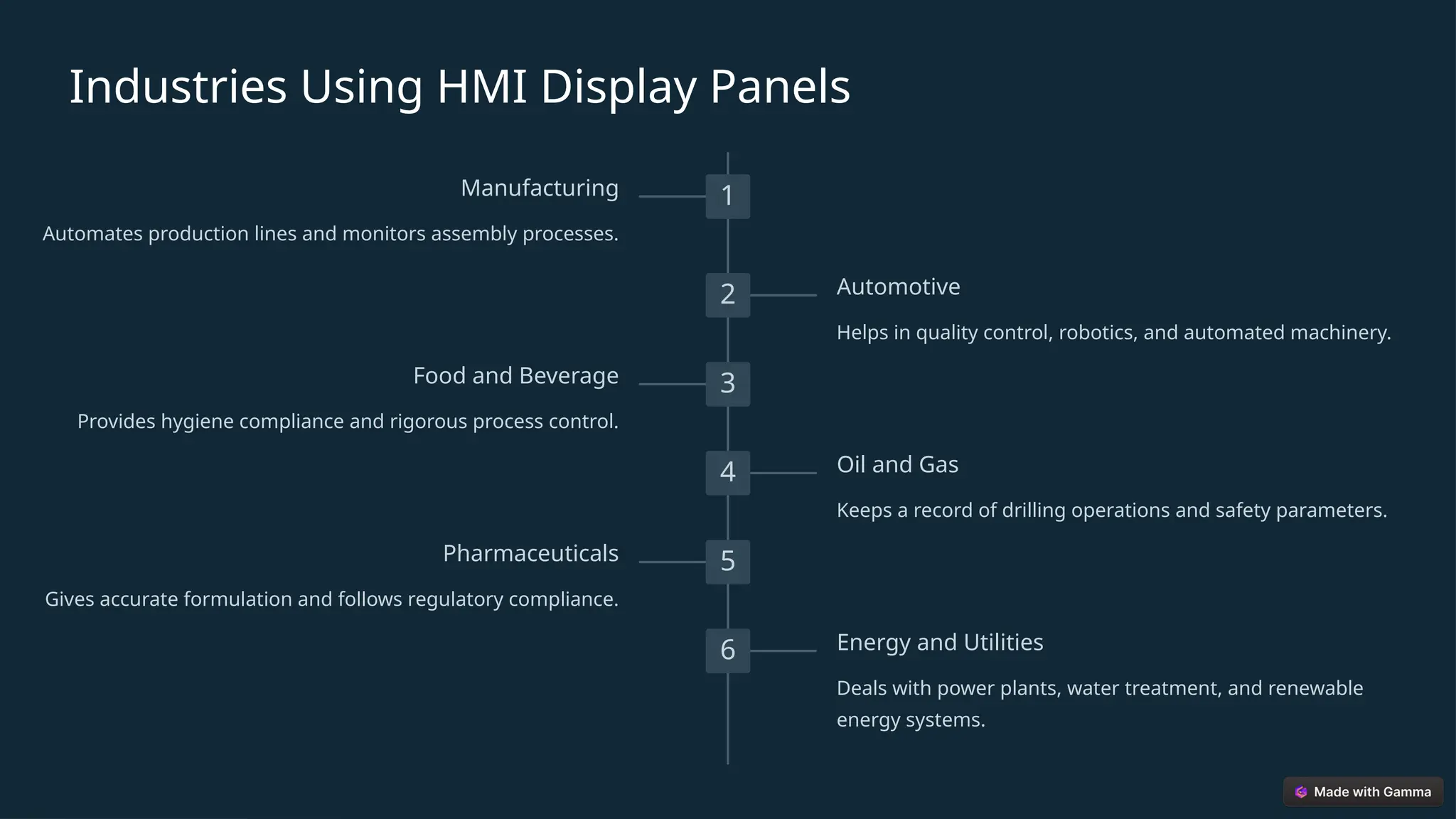

This document discusses the significance of HMI (Human-Machine Interface) display panels in industrial automation, outlining their features, types, and benefits such as enhanced control, real-time data visualization, and improved efficiency. It highlights various industries utilizing HMI panels and identifies future trends including AI and IoT integration, cloud-based systems, and augmented reality interfaces. The presentation emphasizes that HMI panels are vital for optimizing operations and reducing downtime in industrial settings.