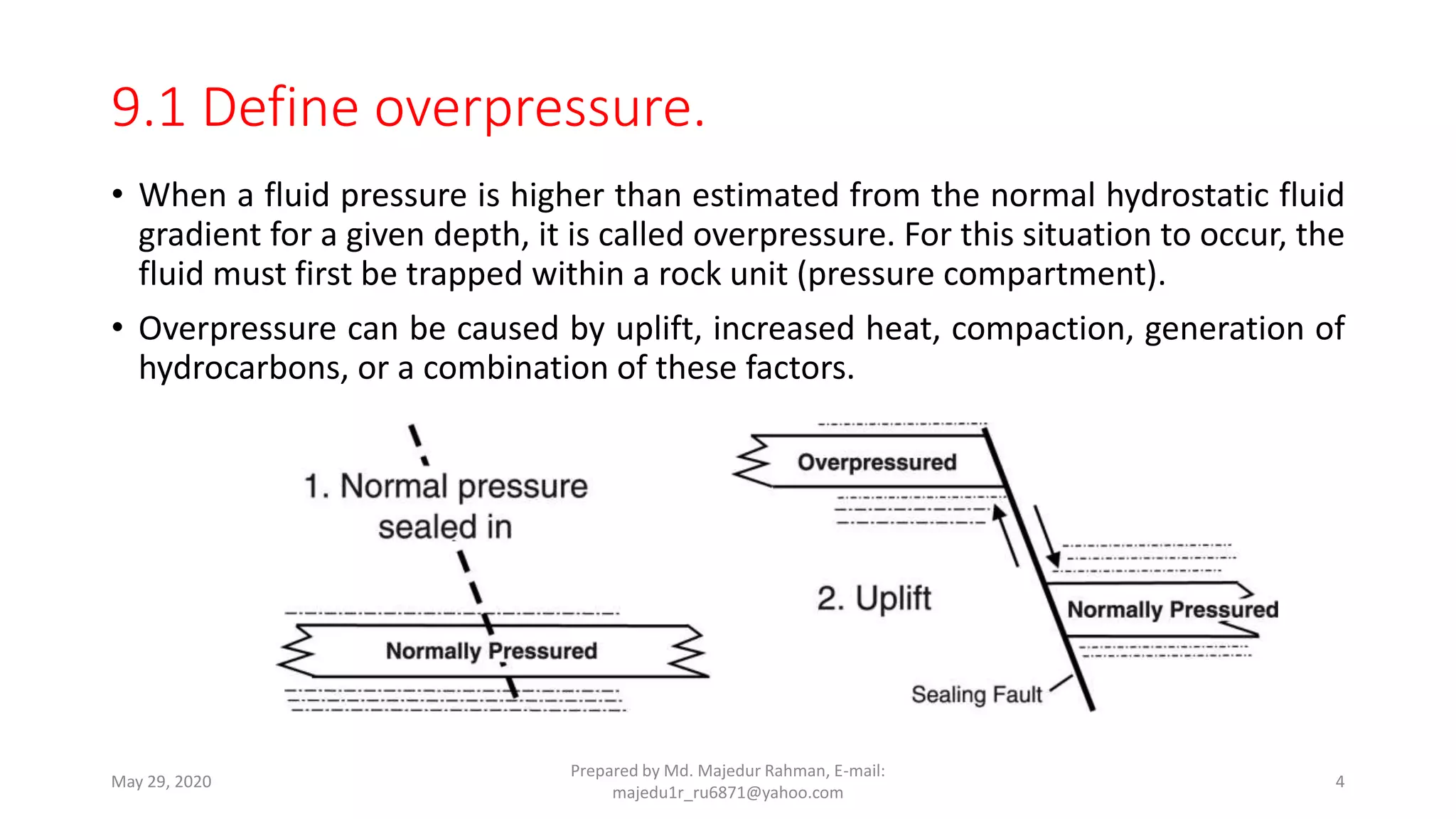

The document presents an educational overview of well control and blowout prevention techniques for students in their 7th semester of mining at Bogura Polytechnic Institute. It covers essential concepts such as overpressure, causes of well kicks, blowout prevention systems, the importance of proper planning, and various well shutdown procedures. Additionally, it discusses fishing operations for retrieving lost objects in boreholes and emphasizes the significance of effective drilling practices to mitigate risks.