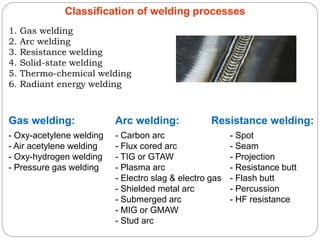

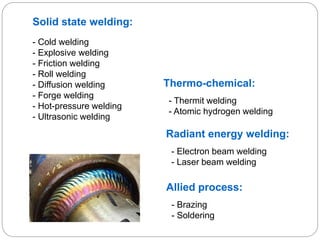

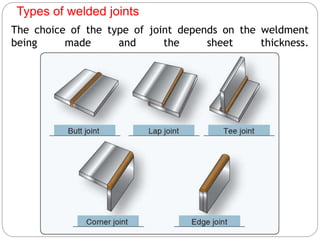

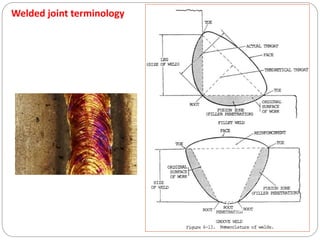

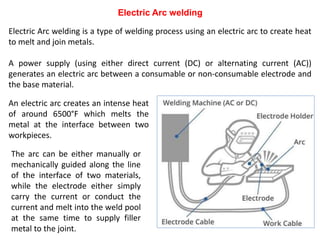

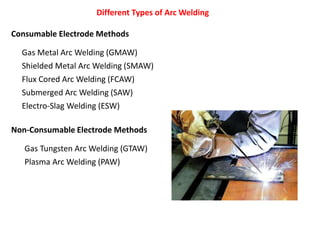

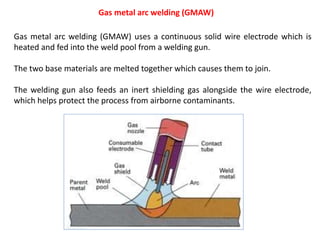

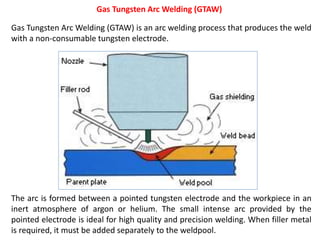

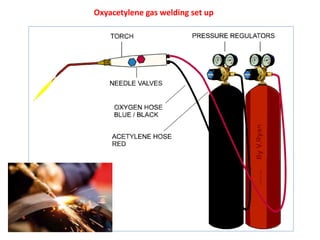

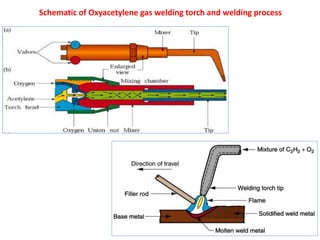

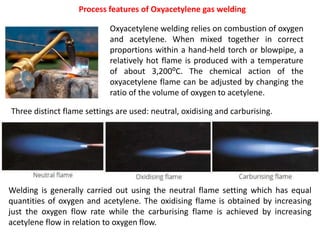

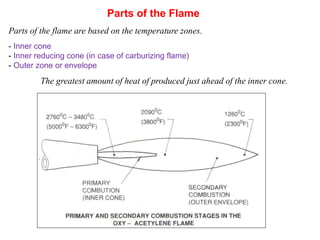

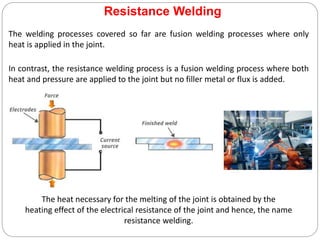

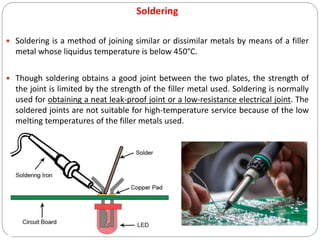

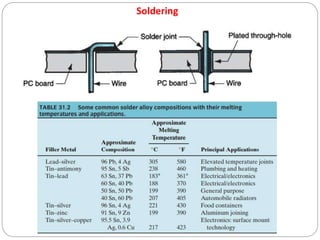

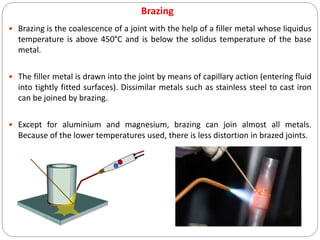

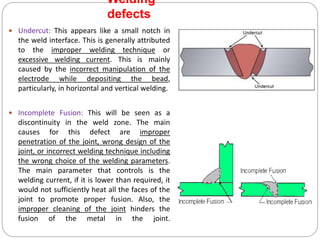

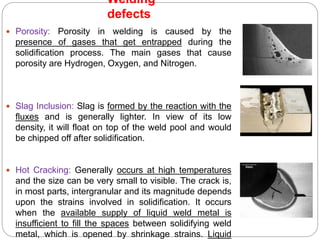

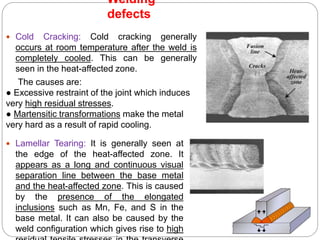

The document discusses secondary manufacturing processes, specifically focusing on welding fabrication techniques, which involve joining materials either permanently or temporarily. It elaborates on various welding methods, including gas welding, arc welding, and resistance welding, as well as the types of joints and techniques used in welding practices. The document also covers common welding defects and their causes, emphasizing the complexities involved in achieving quality welds.