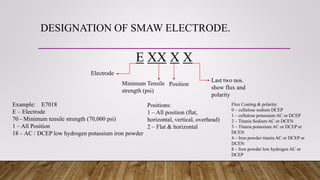

This document provides an overview of welding and career opportunities in welding technology. It begins by classifying welding into solid state welding and liquid state welding. It then discusses power sources for welding, including transformers, alternators, and electric generators. The document covers polarity for AC and DC output and electrode designation codes. It provides examples of electrode types and discusses factors for selecting electrodes, such as the base metal properties, welding current, and service conditions. Finally, it discusses career opportunities in welding technology.