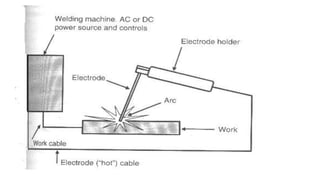

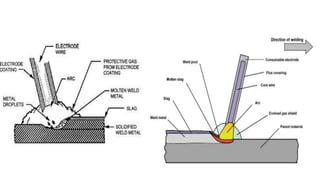

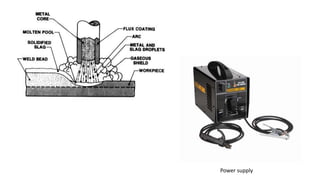

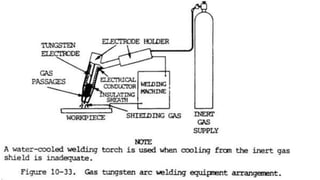

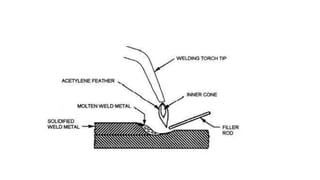

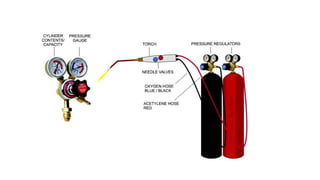

Welding is a fabrication process that joins materials like metals by melting them together with heat and sometimes pressure. There are different types of welding including arc welding, which uses an electric arc to melt metals, and gas welding (oxyacetylene welding), which uses fuel gases and oxygen applied through a torch. Specific arc welding methods include shielded metal arc welding, gas tungsten arc welding, and others that use consumable or non-consumable electrodes to create the arc and melt the materials. Equipment for gas welding includes oxygen and fuel gas cylinders, regulators, hoses, and a torch.