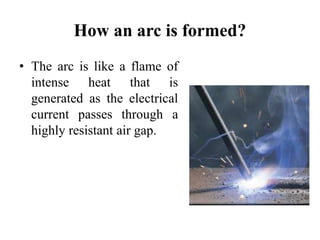

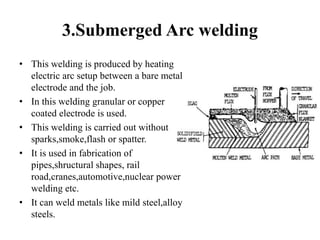

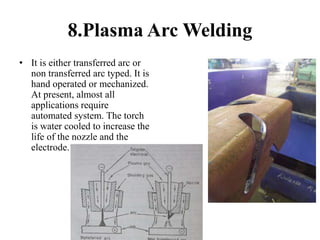

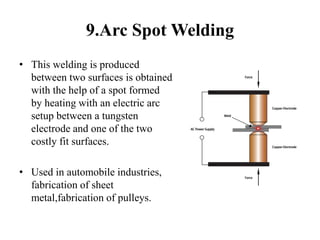

Arc welding is a group of processes that join metal pieces by generating heat from an electric arc, which can be performed with or without filler metal. Various methods include carbon arc, shielded metal, submerged arc, TIG, MIG, electroslag, electrogas, plasma arc, arc spot, and stud arc welding, each having specific applications and materials suitable for welding. This technology is widely used in industries like construction, automotive, shipbuilding, and manufacturing due to its efficiency and versatility.