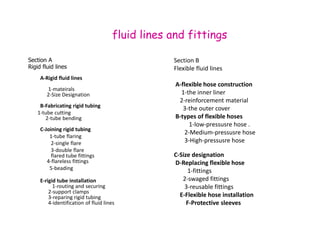

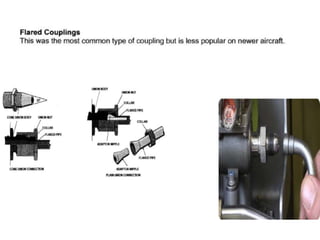

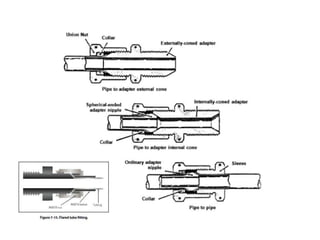

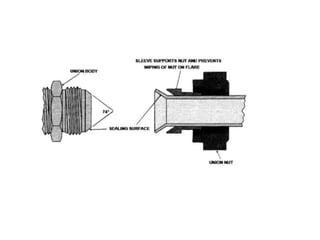

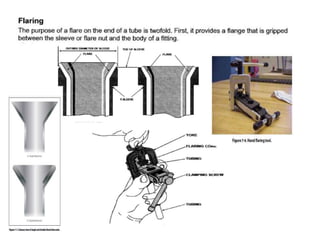

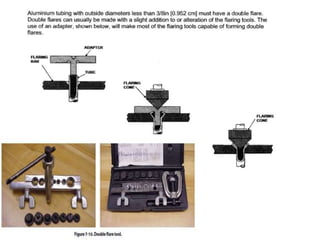

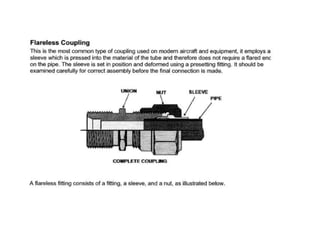

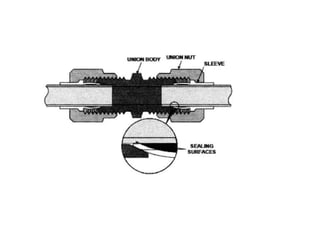

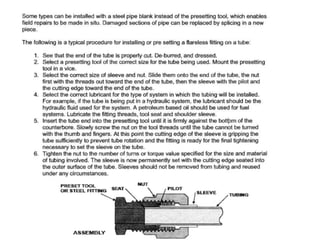

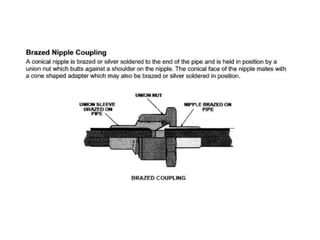

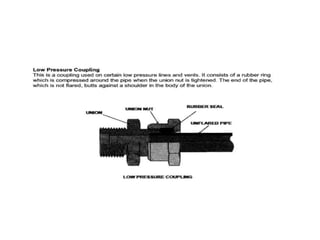

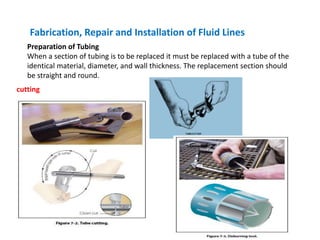

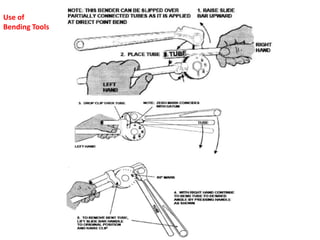

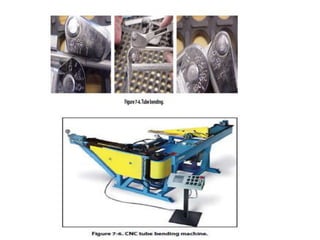

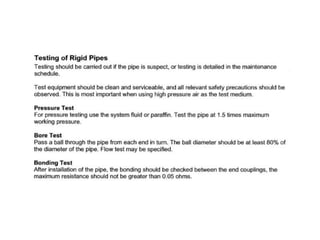

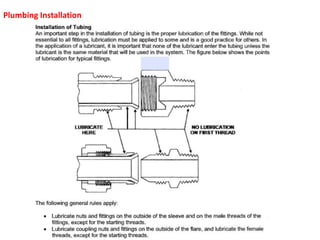

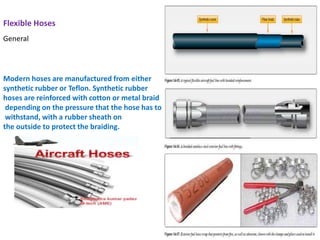

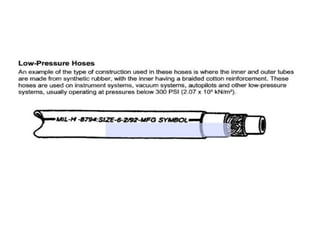

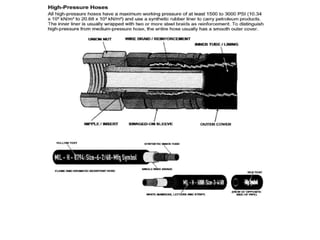

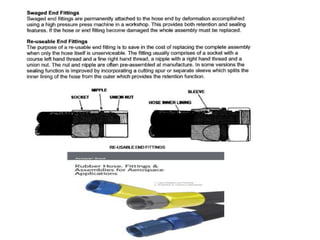

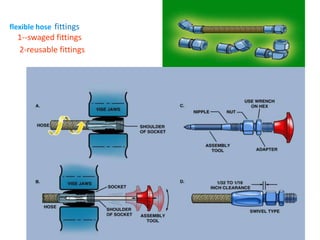

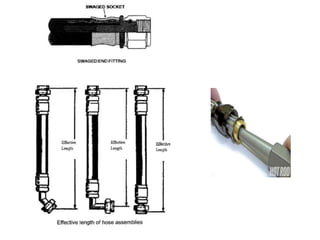

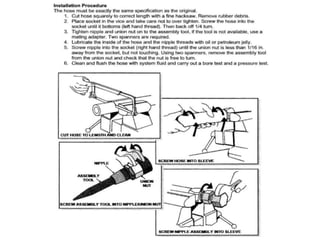

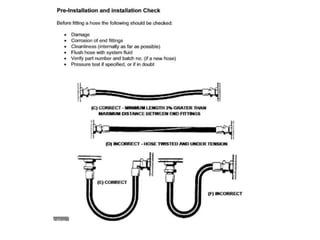

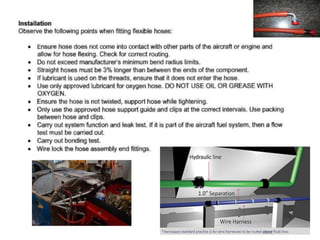

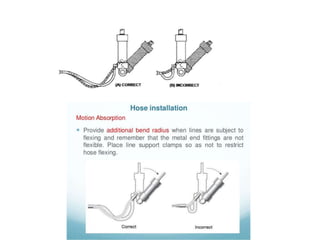

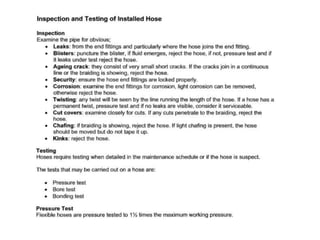

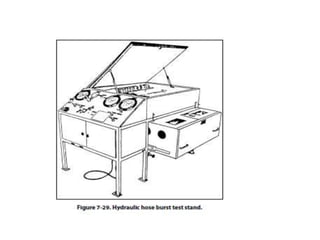

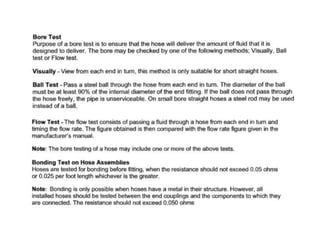

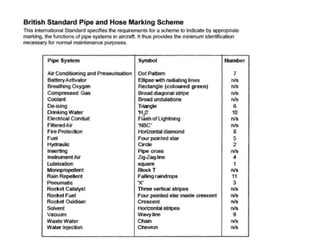

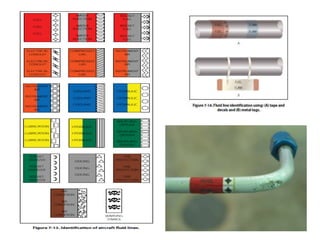

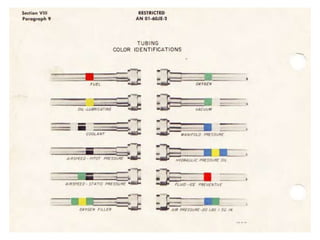

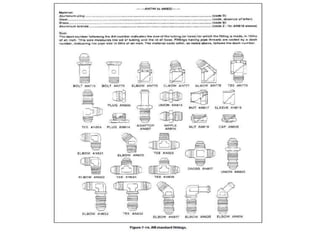

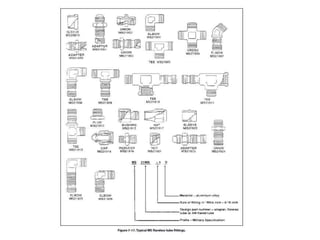

This document discusses pipes and unions used for aircraft systems. It describes rigid pipes made from materials like stainless steel, aluminum alloys, and copper alloys. Flexible hoses are constructed with an inner liner, reinforcement, and outer cover. Rigid pipes are joined using methods like flaring and bead rolling. Flexible hoses use fittings like swaged or reusable fittings. The document provides safety guidelines and describes fabricating, repairing, and installing both rigid pipes and flexible hoses on aircraft.