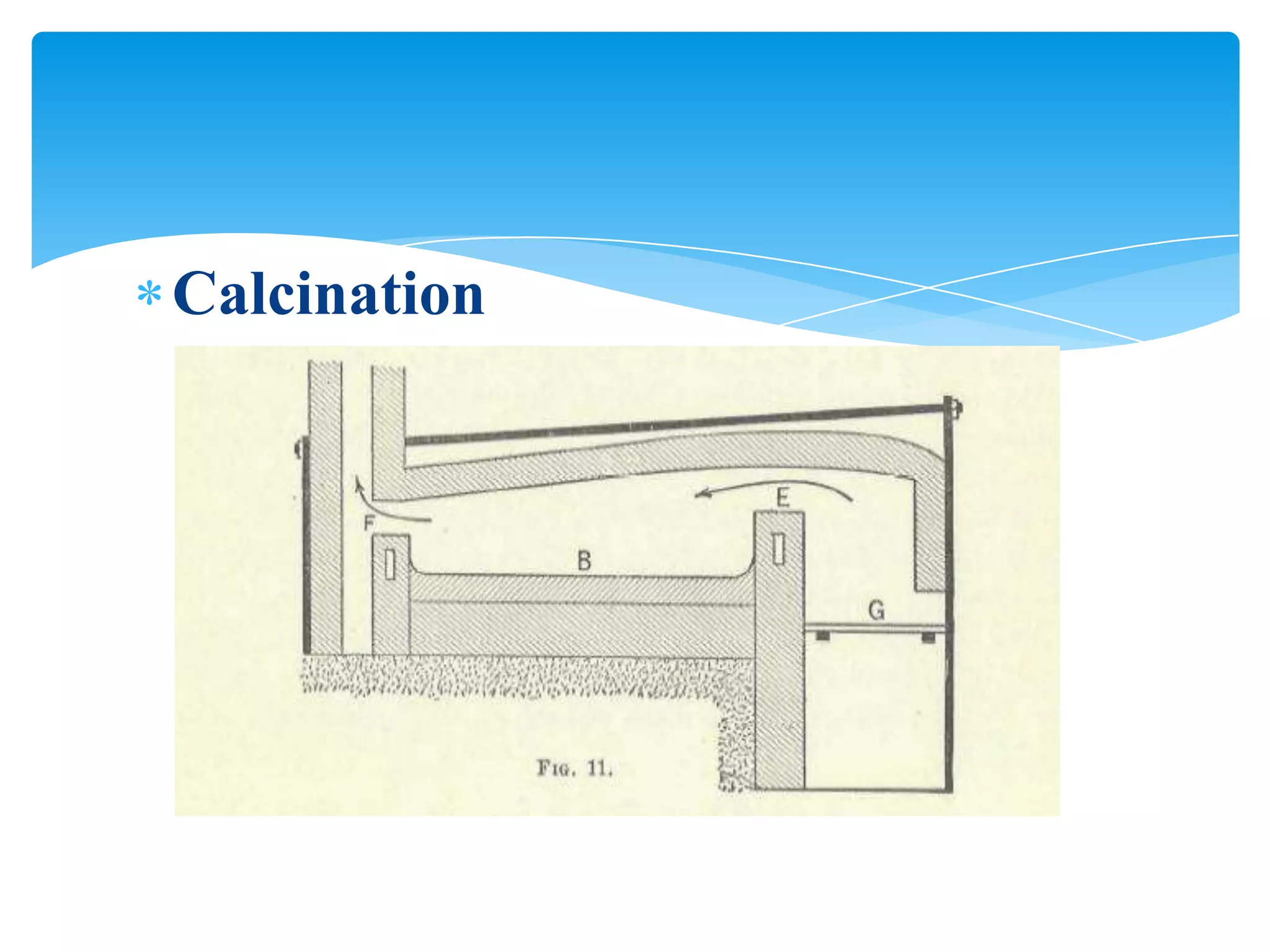

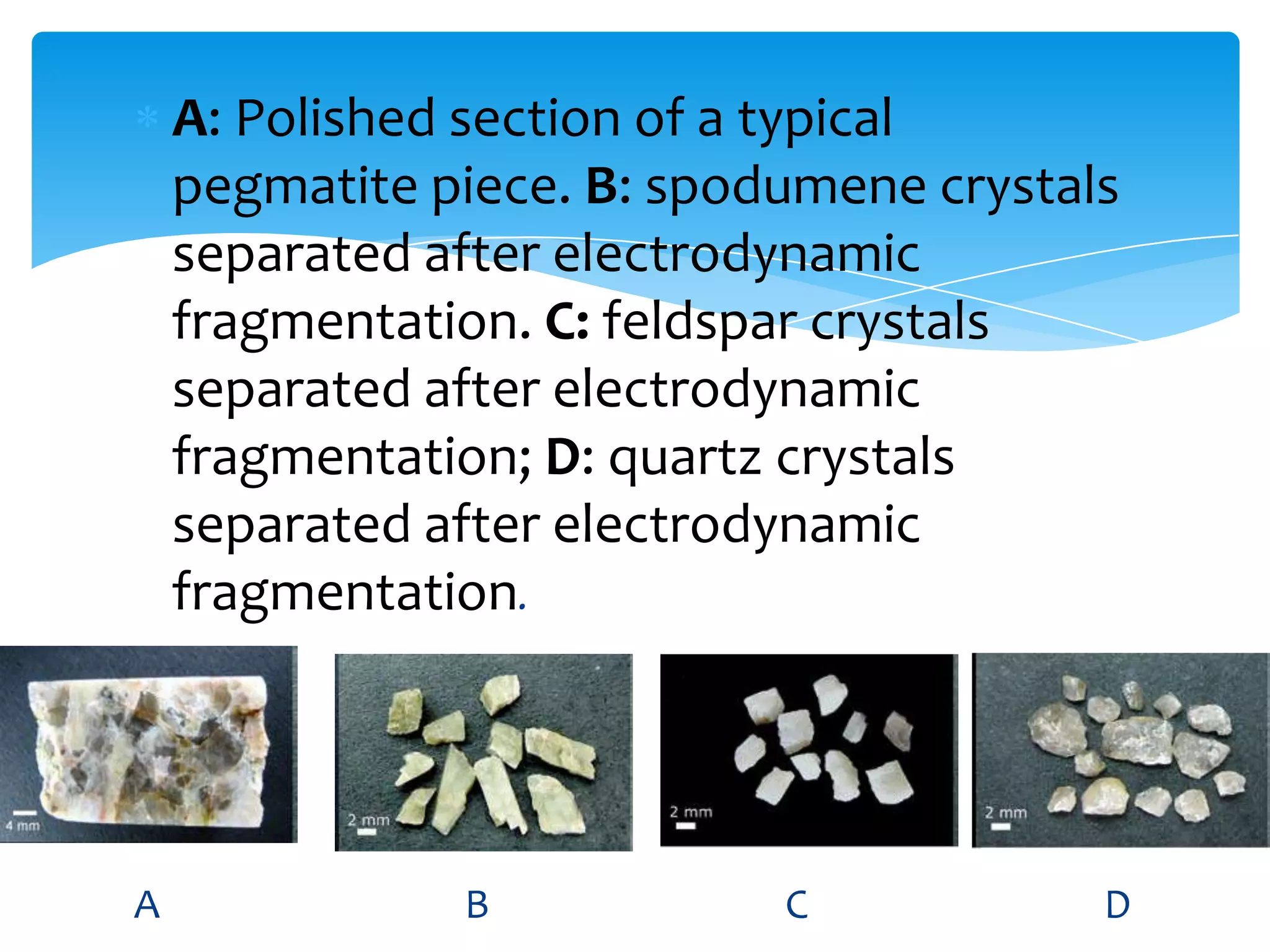

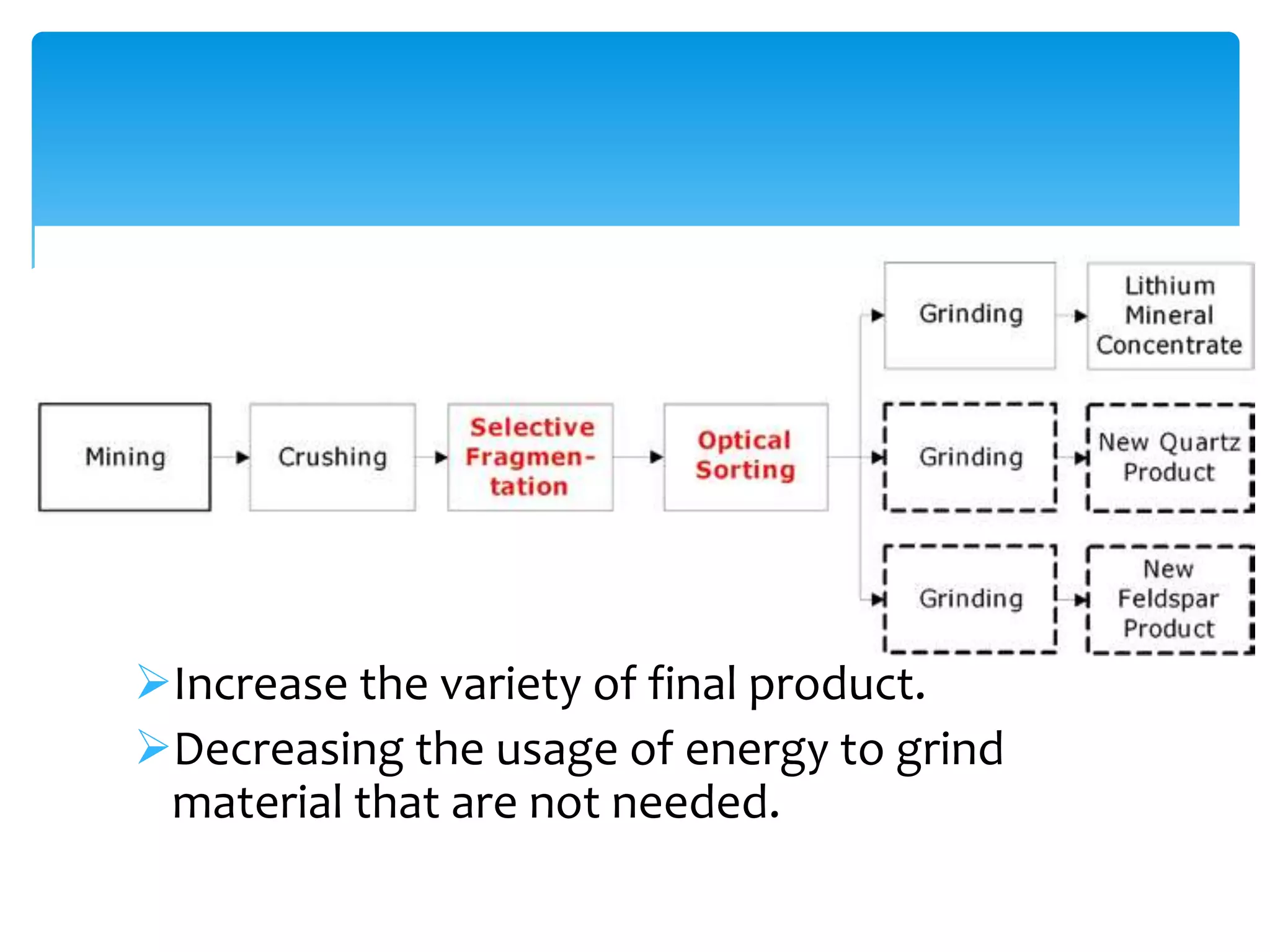

This document discusses several ways to improve the extraction of ores like aluminum, lithium, and other minerals. It describes processes like indirect carbothermic reduction and calcination that can extract aluminum using less energy and carbon emissions than traditional methods. It also outlines a fusion method for extracting lithium chloride from silicate minerals, which can then be electrolyzed to produce pure lithium metal. New analytical methods like electrodynamic fragmentation are highlighted as well, which allow for the selective separation of minerals like spodumene, feldspar, and quartz to increase final product variety while decreasing unnecessary energy use.