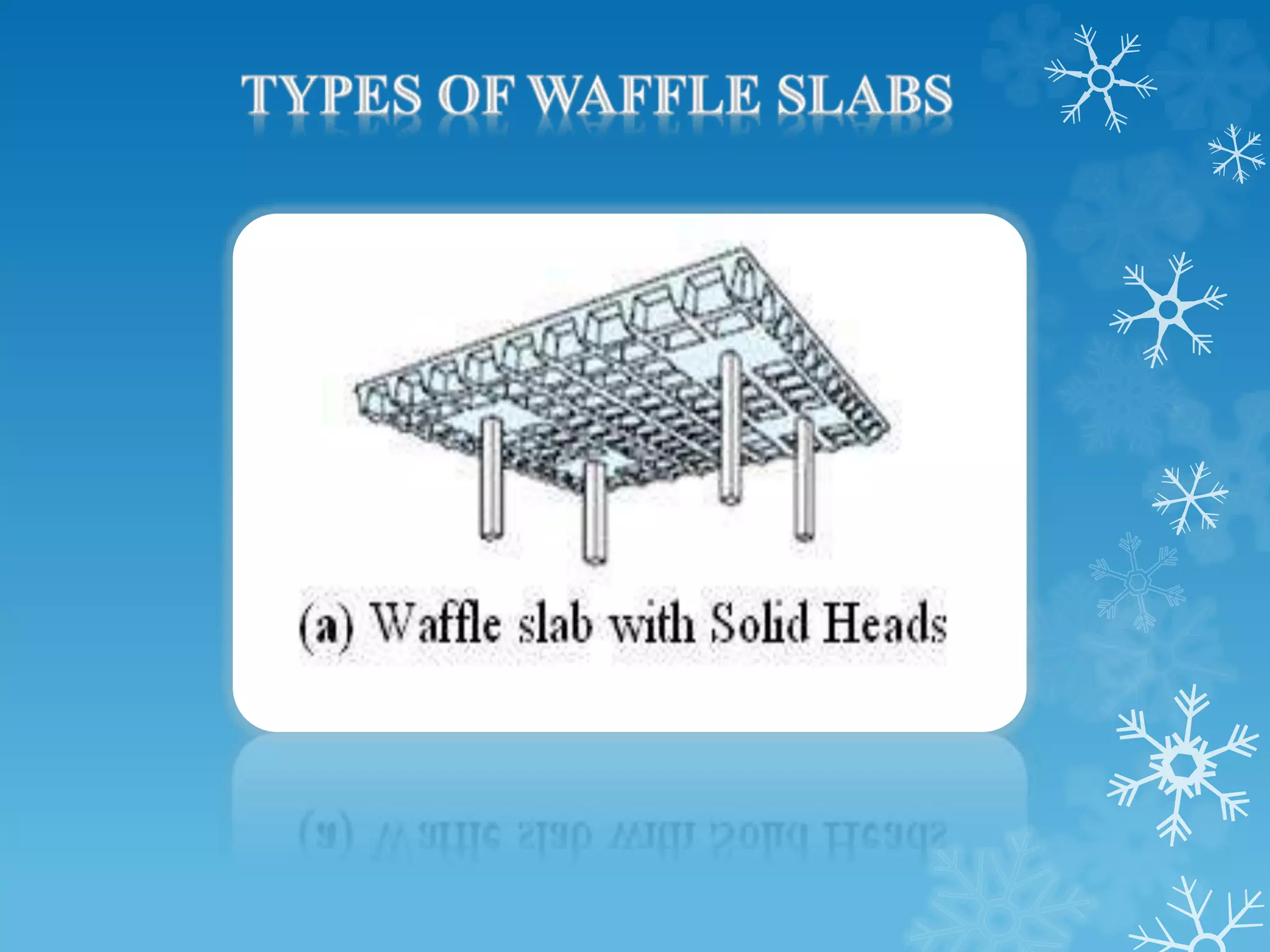

This document presents a comparative study of reinforced concrete (RCC) waffle slabs versus prestressed concrete waffle slabs. It aims to determine the most economical design for different span lengths, studying structural behavior through software analysis and manual calculations. For spans over 25 meters, prestressed design is found to be more cost effective. The document also reviews previous literature analyzing waffle slab optimization and behavior under different loading and boundary conditions.

![CASE STUDY :-

J. Prasad[1], S. Chander[2], A.K. Ahuja[3]; “Optimum Dimensions of Waffle

Slab for Medium Size Floors”, Asian Journal of Civil Engineering VOL. 6, No.

3(2005).

The author shows the results from the analysis carried out on waffle slab

medium size floor system with a view to achieve the optimum dimensions

of rib spacing, its depth and width.

In order to carry out parametric investigation to arrive at optimum values

of rib number and dimensions for a given floor size, the waffle slabs with

square floor plans of size 6×6 m, 7×7 m and 8×8 m have been considered

for 3 kN/m2 and 5 kN/m2 of Live Load & Floor finish 1.5 kN/m2

In order to evaluate dead loads unit-weight of R.C.C. as 25 kN/m3 has

taken](https://image.slidesharecdn.com/waffleslab-180307053416/75/Waffle-slab-9-2048.jpg)

![REFREANCES:-

J. Prasad[1], S. Chander[2], A.K. Ahuja[3]; “Optimum Dimensions of

Waffle Slab for Medium Size Floors”, Asian Journal of Civil Engineering

VOL. 6, No. 3(2005).

Chowdhury [1], J. P. Singh [2]; “Analysis and Design of Waffle Slab with

different Boundary Conditions”, The Indian Concrete Journal (2015).

Somasekhar [1], P. Prabhakaran [2]; “Analysis of Concrete Waffle Slab

with Opening”, International Journal of Emerging Technology and

Advanced Engineering VOL. 5, Issue 9 (2015).

A. C. Galeb[1], Z. F. Atiyah[2]; “Optimum design of reinforced concrete

waffle slabs”, International Journal of Civil And Structural Engineering

Volume 1, No 4, (2011).

Ibrahim Arman[1]; “Analysis of two- way ribbed and waffle slabs with

hidden beams”, International Journal For Computational Civil AND

Structural Engineering · January (2014).](https://image.slidesharecdn.com/waffleslab-180307053416/75/Waffle-slab-16-2048.jpg)