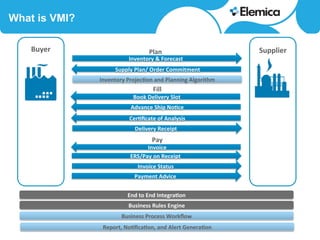

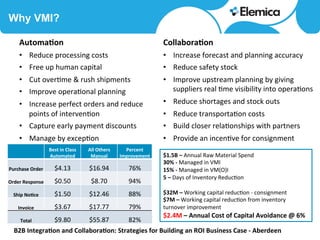

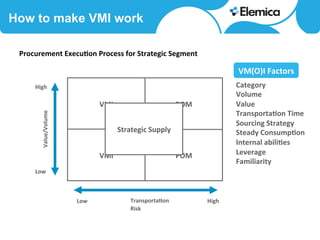

This document discusses building a vendor managed inventory (VMI) program to drive working capital savings. It defines VMI as a collaboratively managed order replenishment solution that provides suppliers tools to create optimized delivery schedules through shared visibility into forecasts and inventory levels. The document outlines benefits of VMI such as reduced costs from automation and improved collaboration. It provides best practices for a VMI program including automating standard processes, change management, and building a supplier network foundation before implementing more advanced strategies.