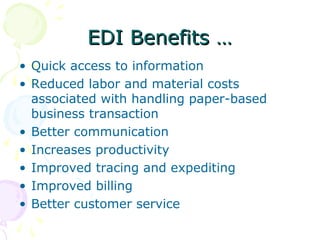

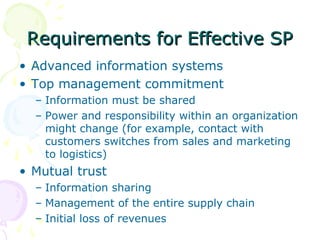

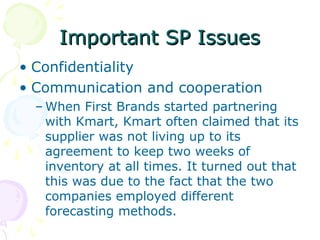

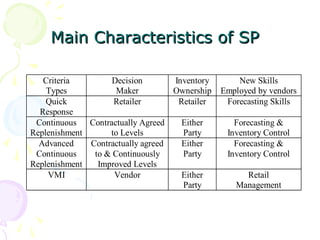

This document discusses different types of strategic partnering (SP) between suppliers and retailers, including quick response, continuous replenishment, advanced continuous replenishment, and vendor managed inventory. It provides examples of SP implementations between companies like Milliken and department stores, Walmart and suppliers, and Dillard's, JC Penney, and Walmart with their suppliers. The document also outlines advantages and disadvantages of SP, as well as requirements, issues, implementation steps, and examples of both successful and unsuccessful SP arrangements.