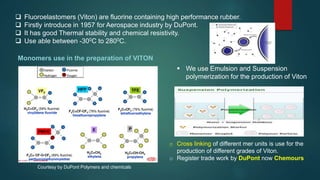

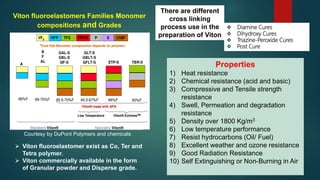

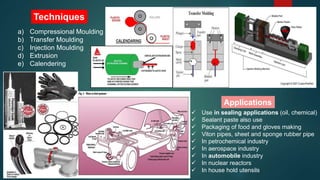

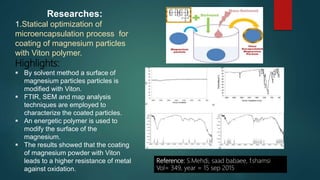

Viton is a fluoroelastomer introduced in 1957 for use in the aerospace industry. It has excellent thermal stability and chemical resistance, being usable between -30°C to 280°C. Viton exists as co, ter, and tetra polymers and is commercially available as granular powder or dispersions. It has many applications due to its heat resistance, strength, and resistance to chemicals, hydrocarbons, weathering and oxidation. Research has shown Viton can act as a thermally stable binder and be used to coat magnesium particles to increase their oxidation resistance.