The document discusses the properties and applications of several fluoropolymer materials:

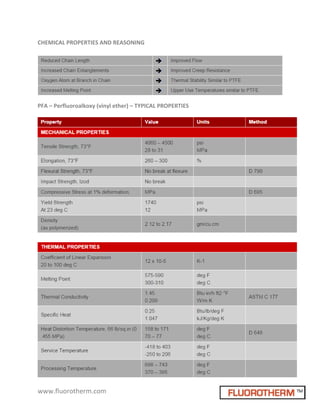

- PFA (perfluoroalkoxy) is chemically inert and resistant to strong acids/bases. It is used in non-shrink tubing, heat exchangers, medical tubing, cable coating, and lining chemical equipment.

- PVDF (polyvinylidene fluoride) has high purity and strength, resisting solvents, acids, bases and heat. It is used where its lower melting point is advantageous for melt processing.

- PCTFE (polychlorotrifluoroethylene) is rigid with low gas permeability and compressive strength. It maintains properties at high temperatures and in chemicals.

-